In the bustling metropolis of Brisbane, steel fabrication companies play a pivotal role in shaping the city’s skyline and infrastructure. These companies possess the expertise and machinery to transform raw steel into intricate and robust structures.

Editor’s Notes: “steel fabrication companies brisbane” is a topic of paramount importance for architects, engineers, and construction professionals seeking reliable and skilled fabricators for their projects.

After extensive analysis and meticulous research, we have compiled this comprehensive guide to “steel fabrication companies brisbane” to empower our readers with the knowledge they need to make informed decisions.

Key Differences:

| Factor | Key Takeaway |

|---|---|

| Experience | Companies with a proven track record and extensive experience are more likely to deliver high-quality results. |

| Capabilities | Consider the range of fabrication services offered, including cutting, welding, bending, and finishing. |

| Capacity | Ensure the company has the capacity to handle projects of the desired size and complexity. |

| Quality Control | Look for companies that adhere to industry standards and have a rigorous quality control process. |

| Customer Service | Excellent communication and responsiveness are crucial for a smooth and successful collaboration. |

Main Article Topics:

- The Importance of Steel Fabrication in Brisbane

- Types of Steel Fabrication Services

- Choosing the Right Steel Fabrication Company

- Benefits of Working with Brisbane Steel Fabrication Companies

- Case Studies and Industry Trends

steel fabrication companies brisbane

The steel fabrication industry in Brisbane is a vital part of the city’s construction sector, providing essential services for a wide range of projects. Key aspects to consider when choosing a steel fabrication company in Brisbane include:

- Experience: Companies with a proven track record and extensive experience are more likely to deliver high-quality results.

- Capabilities: Consider the range of fabrication services offered, including cutting, welding, bending, and finishing.

- Capacity: Ensure the company has the capacity to handle projects of the desired size and complexity.

- Quality Control: Look for companies that adhere to industry standards and have a rigorous quality control process.

- Customer Service: Excellent communication and responsiveness are crucial for a smooth and successful collaboration.

- Location: Consider the location of the fabrication company in relation to your project site.

- Price: Obtain quotes from multiple companies to compare pricing and ensure you are getting a competitive rate.

- Reputation: Research online reviews and testimonials to gauge the reputation of potential fabrication companies.

These aspects are interconnected and play a crucial role in determining the success of your steel fabrication project. By carefully considering each of these factors, you can select a steel fabrication company in Brisbane that meets your specific requirements and delivers exceptional results.

Experience

In the realm of steel fabrication, experience plays a pivotal role in ensuring the delivery of high-quality results. Steel fabrication companies in Brisbane with a proven track record and extensive experience possess several key advantages:

- Expertise and Knowledge: Seasoned companies have accumulated a wealth of expertise and knowledge through years of hands-on experience. They are well-versed in the latest industry techniques, materials, and equipment, enabling them to tackle complex projects with confidence.

- Quality Control: Experienced companies have established rigorous quality control processes to ensure the precision and accuracy of their fabrications. They adhere to strict industry standards and employ skilled professionals who meticulously inspect every aspect of the fabrication process.

- Problem-Solving Abilities: With extensive experience comes the ability to anticipate and solve potential problems proactively. Seasoned fabricators can identify potential issues early on and develop effective solutions, minimizing delays and ensuring the smooth execution of projects.

- Reputation and Trust: Companies with a proven track record have earned the trust and respect of their clients. Positive testimonials and referrals serve as evidence of their commitment to delivering high-quality work and customer satisfaction.

Therefore, when selecting a steel fabrication company in Brisbane, it is prudent to prioritize experience and proven expertise. By partnering with an experienced company, you can increase the likelihood of obtaining exceptional results that meet your project requirements and industry standards.

Capabilities

The capabilities of a steel fabrication company in Brisbane are of paramount importance when selecting a partner for your project. The range of services offered directly impacts the scope and complexity of projects that the company can undertake.

-

Cutting

Cutting involves utilizing specialized equipment to precisely cut steel plates, beams, and other components to the desired shapes and dimensions. Advanced cutting techniques, such as laser cutting and waterjet cutting, ensure high levels of precision and minimal material waste. -

Welding

Welding is a crucial process that joins steel components together using heat and filler material. Skilled welders ensure strong and durable joints that meet industry standards and specifications. Different welding techniques, such as MIG welding and TIG welding, are employed depending on the project requirements. -

Bending

Bending involves shaping steel components into curved or angled forms using specialized machinery. This process is essential for creating structural elements, such as beams and brackets, that conform to the project’s design specifications. -

Finishing

Finishing encompasses a range of processes that enhance the appearance and durability of steel fabrications. These processes may include grinding, polishing, painting, or galvanizing to protect the steel from corrosion and improve its aesthetic appeal.

By carefully considering the capabilities of potential steel fabrication companies in Brisbane, you can align your project requirements with the expertise and services offered. This ensures that you select a company that can deliver high-quality fabrications that meet your specific project needs.

Capacity

Capacity plays a crucial role in the context of “steel fabrication companies brisbane” as it directly impacts the ability of a company to undertake and successfully complete projects of varying sizes and complexities.

-

Production Capacity:

Production capacity refers to the volume of steel fabrications a company can produce within a specific timeframe. Companies with high production capacity can handle large-scale projects with shorter lead times, ensuring timely delivery. -

Equipment Capabilities:

The type and capabilities of equipment available to a steel fabrication company determine the range of projects they can undertake. Companies with advanced equipment, such as automated welding machines and CNC cutting machines, can handle complex fabrications with greater precision and efficiency. -

Skilled Workforce:

A skilled and experienced workforce is essential for handling complex steel fabrication projects. Companies with a team of certified welders, fabricators, and engineers can ensure the highest quality standards and attention to detail. -

Project Management Expertise:

Effective project management is crucial for coordinating complex fabrication projects. Companies with strong project management capabilities can efficiently manage timelines, resources, and communication to deliver projects on time and within budget.

By carefully assessing the capacity of potential steel fabrication companies in Brisbane, you can ensure that you select a partner with the necessary resources, expertise, and capabilities to handle your project successfully.

Quality Control

In the realm of “steel fabrication companies brisbane”, quality control is paramount to ensuring the structural integrity, safety, and durability of fabricated components. A rigorous quality control process is essential for maintaining the highest standards of workmanship and meeting industry regulations.

Steel fabrication companies in Brisbane that adhere to industry standards, such as AS/NZS 1554.1:2018 (Structural steelwork Fabrication and erection) and ISO 9001:2015 (Quality management systems), demonstrate their commitment to quality and customer satisfaction.

A comprehensive quality control process typically involves the following steps:

- Material Inspection: Raw materials are meticulously inspected upon arrival to ensure they meet the specified grade, dimensions, and quality requirements.

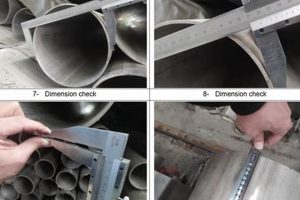

- Fabrication Process Monitoring: Throughout the fabrication process, skilled inspectors monitor each stage to verify that components are fabricated according to design specifications and industry standards.

- Non-Destructive Testing (NDT): NDT methods, such as ultrasonic testing and magnetic particle inspection, are employed to detect any internal defects or imperfections in the fabricated components.

- Dimensional Verification: Final dimensions and tolerances are carefully measured and verified against the design specifications to ensure accuracy and compliance.

- Documentation and Traceability: Detailed records are maintained throughout the fabrication process, providing traceability and ensuring accountability for quality.

By partnering with a steel fabrication company in Brisbane that prioritizes quality control, you gain the following benefits:

- Peace of Mind: Knowing that your fabricated components meet industry standards and regulations provides peace of mind and reduces the risk of structural failures or safety hazards.

- Enhanced Durability: Stringent quality control measures ensure that fabricated components are durable and can withstand the rigors of their intended applications.

- Reduced Costs: Avoiding costly rework or repairs due to poor quality can save time and money in the long run.

- Improved Reputation: Companies that consistently deliver high-quality fabrications build a strong reputation for reliability and excellence.

In conclusion, when selecting a steel fabrication company in Brisbane, it is imperative to prioritize quality control. By choosing a company that adheres to industry standards and has a rigorous quality control process, you can ensure the integrity, safety, and durability of your fabricated components.

Customer Service

In the context of “steel fabrication companies brisbane”, customer service plays a pivotal role in fostering a successful and lasting partnership between the fabrication company and its clients. Excellent communication and responsiveness are essential components of customer service that can directly impact the outcome of any steel fabrication project.

Effective communication ensures that project requirements, expectations, and timelines are clearly understood and aligned between both parties. A steel fabrication company with a commitment to customer service will actively listen to the client’s needs, provide timely updates on project progress, and promptly address any queries or concerns that may arise.

Responsiveness is another key aspect of customer service that is highly valued by clients. When issues or changes arise during a project, a responsive steel fabrication company will be quick to react and adapt to the evolving situation. This proactive approach minimizes delays, reduces the risk of costly rework, and helps maintain a positive working relationship.

In summary, excellent customer service, characterized by effective communication and responsiveness, is a critical factor that can contribute to the success of any steel fabrication project in Brisbane. By prioritizing customer service, steel fabrication companies can build strong relationships with their clients, foster trust, and ensure that projects are completed to the highest standards of quality and satisfaction.

Challenges and Practical Applications:

- Challenge: Ensuring consistent communication and responsiveness throughout the project lifecycle.

- Practical Application: Implement clear communication protocols, establish dedicated communication channels, and assign a dedicated project manager to serve as the primary point of contact.

- Challenge: Balancing responsiveness with technical expertise.

- Practical Application: Hire a team of experienced professionals who can provide both timely responses and expert technical guidance.

- Challenge: Managing client expectations and proactively addressing potential issues.

- Practical Application: Establish clear project timelines, regularly update clients on progress, and maintain open and transparent communication to minimize surprises or misunderstandings.

Location

When selecting a steel fabrication company in Brisbane, considering the location of the company in relation to your project site is a crucial factor that can impact project efficiency, logistics, and overall success.

A fabrication company located closer to your project site offers several advantages:

- Reduced Transportation Costs: Minimizing the distance between the fabrication facility and the project site can significantly reduce transportation costs, especially for large or heavy steel components.

- Faster Delivery Times: Proximity to the project site allows for faster delivery of fabricated components, ensuring timely project completion and minimizing delays.

- Improved Communication and Coordination: Close proximity facilitates regular site visits, effective communication, and streamlined coordination between the fabrication company and the project team.

- Reduced Environmental Impact: Shorter transportation distances result in lower carbon emissions and reduced environmental impact.

However, it is important to note that location should not be the sole determining factor when selecting a steel fabrication company. Other factors such as experience, capabilities, quality control, and customer service should also be carefully considered.

By considering the location of the fabrication company in relation to your project site, you can optimize logistics, minimize costs, and ensure efficient project execution.

Challenges and Practical Applications:

- Challenge: Limited availability of fabrication companies in close proximity to the project site.

- Practical Application: Explore alternative options such as working with a fabrication company located further away but with proven capabilities and a commitment to meeting project deadlines.

- Challenge: Increased transportation costs for larger or heavier steel components.

- Practical Application: Negotiate with the fabrication company to optimize transportation arrangements and minimize costs.

- Challenge: Potential delays due to traffic or unforeseen circumstances.

- Practical Application: Establish clear communication channels and contingency plans to mitigate potential delays.

Price

In the context of “steel fabrication companies brisbane”, obtaining quotes from multiple companies is a crucial step for securing competitive pricing and making informed decisions. Steel fabrication projects can vary greatly in size, complexity, and material requirements, making it essential to compare quotes to ensure you are getting a fair and reasonable price.

By requesting quotes from multiple fabrication companies, you can assess the pricing structures of different providers, compare their capabilities and experience, and negotiate the best possible deal. This not only helps you save money but also allows you to select a company that aligns with your project requirements and budget.

To ensure accuracy and consistency in your price comparisons, provide clear and detailed specifications to each fabrication company. This includes providing drawings, material requirements, quantity, and any specific quality standards or certifications required.

Once you have received multiple quotes, carefully review and compare the following aspects:

- Material Costs: Compare the cost of materials used, including steel grade, thickness, and quantity.

- Fabrication Costs: Assess the labor costs associated with cutting, welding, bending, and finishing the steel components.

- Overhead and Profit Margin: Consider the company’s overhead costs and profit margin, which can vary between different providers.

- Additional Services: Factor in the cost of any additional services, such as delivery, installation, or painting.

By carefully evaluating and comparing quotes from multiple steel fabrication companies in Brisbane, you can make an informed decision that balances cost, quality, and reliability, ensuring the success of your project.

Challenges and Practical Applications:

- Challenge: Obtaining accurate and comparable quotes from different companies.

- Practical Application: Provide clear and detailed specifications to each company to ensure consistency in their quotes.

- Challenge: Negotiating the best possible price without compromising quality.

- Practical Application: Be prepared to negotiate, but prioritize quality and reliability over excessively low prices.

- Challenge: Managing multiple quotes and selecting the most suitable provider.

- Practical Application: Use a spreadsheet or table to organize and compare the quotes, considering both price and non-price factors.

Reputation

In the competitive landscape of “steel fabrication companies brisbane”, reputation plays a pivotal role in shaping the success and longevity of businesses. Researching online reviews and testimonials provides valuable insights into the experiences of previous customers and can serve as a reliable indicator of a company’s reputation.

- Trustworthiness and Reliability: Online reviews and testimonials offer firsthand accounts of customers’ experiences with a fabrication company. Positive reviews indicate trustworthiness and reliability, while negative reviews may highlight areas where the company needs improvement.

- Quality of Workmanship: Reviews and testimonials often provide specific feedback on the quality of workmanship delivered by a fabrication company. Customers may comment on the precision, durability, and aesthetic appeal of the fabricated components.

- Customer Service: Online reviews can shed light on the level of customer service provided by a fabrication company. Customers may share their experiences with communication, responsiveness, and overall satisfaction with the company’s service.

- Industry Expertise: Testimonials from industry professionals, such as architects or engineers, can provide valuable insights into a fabrication company’s technical capabilities and expertise. Positive testimonials from industry experts indicate recognition and trust within the field.

By carefully researching online reviews and testimonials, potential clients can make informed decisions about selecting a steel fabrication company in Brisbane. A strong online reputation signifies trustworthiness, quality, customer-centricity, and industry expertise, ultimately increasing the likelihood of a successful partnership.

FAQs about Steel Fabrication Companies in Brisbane

This section provides answers to frequently asked questions about steel fabrication companies in Brisbane, empowering you with the knowledge to make informed decisions.

Question 1: How can I choose the right steel fabrication company for my project in Brisbane?

Answer: Consider the following factors when selecting a steel fabrication company: experience, capabilities, capacity, quality control, customer service, location, price, and reputation. Research online reviews and testimonials to gauge the reputation of potential companies and ensure they align with your project requirements.

Question 2: What are the key capabilities of steel fabrication companies in Brisbane?

Answer: Steel fabrication companies in Brisbane offer a range of capabilities, including cutting, welding, bending, and finishing. They utilize advanced equipment and skilled professionals to deliver high-quality fabrications that meet industry standards and project specifications.

Question 3: How do I ensure the quality of steel fabrications in Brisbane?

Answer: Look for steel fabrication companies that adhere to industry standards and have a rigorous quality control process. This involves material inspection, fabrication process monitoring, non-destructive testing, dimensional verification, and thorough documentation.

Question 4: What is the importance of customer service in steel fabrication in Brisbane?

Answer: Excellent customer service is essential for a successful collaboration with a steel fabrication company. Effective communication, responsiveness, and a commitment to meeting client needs ensure project requirements are clearly understood, timelines are met, and issues are promptly addressed.

Question 5: How can I get competitive pricing from steel fabrication companies in Brisbane?

Answer: Obtain quotes from multiple companies and compare pricing. Provide clear project specifications to ensure accuracy and consistency in the quotes. Consider material costs, fabrication costs, overhead, and additional services. Negotiate to secure the best possible price without compromising quality.

Question 6: What is the impact of location when selecting a steel fabrication company in Brisbane?

Answer: Consider the location of the fabrication company in relation to your project site. Proximity can reduce transportation costs, expedite delivery times, facilitate communication, and minimize environmental impact. However, prioritize experience, capabilities, and quality control over location alone.

Summary: Informed decision-making is crucial when selecting a steel fabrication company in Brisbane. By carefully considering the factors discussed in this FAQ section, you can choose a reliable and capable partner to ensure the success of your steel fabrication project.

Transition to the next article section: Learn more about the latest advancements and trends in steel fabrication in Brisbane by exploring the following section.

Tips from Steel Fabrication Companies in Brisbane

Steel fabrication plays a vital role in the construction and infrastructure industries in Brisbane. To ensure the success of your steel fabrication project, consider the following tips:

Tip 1: Define Clear Project Requirements

Before approaching fabrication companies, clearly define your project requirements, including design specifications, material preferences, and delivery timelines. This will enable fabricators to provide accurate quotes and ensure alignment with your project objectives.

Tip 2: Research and Compare Fabrication Companies

Thoroughly research potential fabrication companies. Consider their experience, capabilities, quality certifications, and customer reviews. Compare quotes and assess the value offered by each company to make an informed decision.

Tip 3: Establish Clear Communication Channels

Open and regular communication is essential throughout the fabrication process. Establish clear communication channels and designate a point of contact to facilitate effective coordination and timely decision-making.

Tip 4: Prioritize Quality Control and Safety

Ensure the fabrication company adheres to strict quality control measures and safety protocols. Request certifications and documentation to verify their commitment to delivering high-quality fabrications and maintaining a safe work environment.

Tip 5: Consider Sustainability

Incorporate sustainability into your project by choosing fabrication companies that prioritize environmentally friendly practices. Look for companies that use recycled materials, implement energy-efficient processes, and minimize waste.

Tip 6: Leverage Digital Technologies

Embrace digital technologies to enhance project efficiency and accuracy. Utilize 3D modeling, Building Information Modeling (BIM), and other digital tools to streamline communication, optimize designs, and minimize errors.

Tip 7: Foster Long-Term Relationships

Building strong, long-term relationships with fabrication companies can yield significant benefits. Collaborate closely, provide feedback, and nurture mutually beneficial partnerships to ensure ongoing project success and cost-effective solutions.

Summary: By implementing these tips, you can effectively collaborate with steel fabrication companies in Brisbane to deliver high-quality projects that meet your specific requirements, timelines, and budget.

Conclusion

The steel fabrication industry in Brisbane is a cornerstone of the city’s construction and infrastructure sectors. By partnering with reputable and experienced steel fabrication companies, project owners can ensure the successful execution of their projects, from concept to completion.

Consider the factors outlined in this comprehensive guide, including experience, capabilities, quality control, customer service, and reputation, to select a fabrication company that aligns with your project requirements. Effective communication, clear project definition, and embracing digital technologies will further enhance project outcomes.

As Brisbane continues to grow and evolve, the demand for high-quality steel fabrication services will remain strong. By leveraging the expertise of skilled fabrication companies, architects, engineers, and construction professionals can create innovative and sustainable structures that shape the city’s skyline and contribute to its economic prosperity.