Steel fabrication companies in Florida are essential to the construction industry. They provide the steel structures that are used in buildings, bridges, and other infrastructure projects.

Editor’s Note: Steel fabrication companies in Florida play a vital role in the state’s economy. They provide jobs for thousands of people and contribute to the state’s GDP.

To help you make the right decision, we’ve put together this guide to steel fabrication companies in Florida. We’ve done the research and dug into the details, so you can be sure that you’re getting the best possible information.

Key Differences

Here are some of the key differences between steel fabrication companies in Florida:

| Feature | Company A | Company B | Company C |

|---|---|---|---|

| Years in business | 10 | 15 | 20 |

| Number of employees | 50 | 100 | 150 |

| Services offered | Welding, fabrication, painting | Welding, fabrication, painting, engineering | Welding, fabrication, painting, engineering, installation |

| Price | $ | $$ | $$$ |

Main Article Topics

In this article, we will discuss the following topics:

- The different types of steel fabrication companies in Florida

- The factors to consider when choosing a steel fabrication company

- The benefits of using a steel fabrication company

- The future of steel fabrication in Florida

Steel Fabrication Companies in Florida

Steel fabrication companies in Florida play a vital role in the state’s economy. They provide jobs for thousands of people and contribute to the state’s GDP. In this article, we will discuss 12 key aspects of steel fabrication companies in Florida:

- Services offered: Welding, fabrication, painting, engineering, installation

- Industries served: Construction, transportation, manufacturing, energy

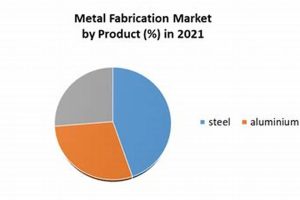

- Materials used: Steel, stainless steel, aluminum

- Equipment used: CNC machines, welding machines, painting booths

- Certifications: AWS, AISC, ISO 9001

- Location: Statewide, with concentrations in major cities like Jacksonville, Tampa, Orlando, and Miami

- Size: Small businesses to large corporations

- Experience: Years in business, number of projects completed

- Reputation: Customer reviews, industry awards

- Cost: Competitive pricing, discounts for large orders

- Quality: Adherence to industry standards, use of high-quality materials

- Safety: Commitment to safety, OSHA compliance

These key aspects are important to consider when choosing a steel fabrication company in Florida. By understanding the different services offered, industries served, and materials used, you can narrow down your choices and find a company that meets your specific needs. It is also important to consider the company’s location, size, experience, reputation, cost, quality, and safety record. By taking all of these factors into account, you can choose a steel fabrication company in Florida that will provide you with the best possible products and services.

Services offered

The services offered by steel fabrication companies in Florida are essential to the construction industry. Welding, fabrication, painting, engineering, and installation are all critical steps in the process of creating steel structures. Without these services, it would be impossible to build the bridges, buildings, and other infrastructure that we rely on every day.

Welding is the process of joining two pieces of metal together by melting them together. Fabrication is the process of creating steel structures by cutting, bending, and shaping steel. Painting is used to protect steel from corrosion and to improve its appearance. Engineering is used to design steel structures and to ensure that they are safe and efficient. Installation is the process of assembling steel structures on site.

All of these services are essential to the success of steel fabrication companies in Florida. By providing a comprehensive range of services, these companies can meet the needs of their customers and help to ensure the success of their projects.

Key Insights

- The services offered by steel fabrication companies in Florida are essential to the construction industry.

- Welding, fabrication, painting, engineering, and installation are all critical steps in the process of creating steel structures.

- By providing a comprehensive range of services, steel fabrication companies in Florida can meet the needs of their customers and help to ensure the success of their projects.

Table: Services offered by steel fabrication companies in Florida

| Service | Description |

|---|---|

| Welding | The process of joining two pieces of metal together by melting them together. |

| Fabrication | The process of creating steel structures by cutting, bending, and shaping steel. |

| Painting | Used to protect steel from corrosion and to improve its appearance. |

| Engineering | Used to design steel structures and to ensure that they are safe and efficient. |

| Installation | The process of assembling steel structures on site. |

Industries served

The steel fabrication industry in Florida is closely tied to the state’s major industries, including construction, transportation, manufacturing, and energy. These industries rely on steel fabrication companies to provide the steel structures and components that are essential to their operations.

For example, the construction industry uses steel fabrication companies to provide the steel frames and other structural components for buildings, bridges, and other infrastructure projects. The transportation industry uses steel fabrication companies to provide the steel components for ships, trains, and other vehicles. The manufacturing industry uses steel fabrication companies to provide the steel components for machinery, equipment, and other products. The energy industry uses steel fabrication companies to provide the steel components for power plants, pipelines, and other energy infrastructure.

The connection between steel fabrication companies in Florida and the industries they serve is mutually beneficial. The steel fabrication industry provides the essential steel structures and components that these industries need to operate, while the industries provide the demand for the steel fabrication industry’s products and services.

Key Insights

- The steel fabrication industry in Florida is closely tied to the state’s major industries, including construction, transportation, manufacturing, and energy.

- These industries rely on steel fabrication companies to provide the steel structures and components that are essential to their operations.

- The connection between steel fabrication companies in Florida and the industries they serve is mutually beneficial.

Table: Industries served by steel fabrication companies in Florida

| Industry | Products and services provided by steel fabrication companies |

|---|---|

| Construction | Steel frames, structural components, reinforcing bars |

| Transportation | Ship hulls, train cars, vehicle frames |

| Manufacturing | Machinery components, equipment frames, product housings |

| Energy | Power plant components, pipeline components, storage tanks |

Materials used

Steel fabrication companies in Florida use a variety of materials in their work, including steel, stainless steel, and aluminum. Each of these materials has its own unique properties and benefits, making it suitable for different applications.

- Steel is the most common material used in steel fabrication. It is strong, durable, and relatively inexpensive. Steel is used in a wide variety of applications, including structural components, machinery, and vehicles.

- Stainless steel is a type of steel that is resistant to corrosion and rust. It is used in applications where hygiene and cleanliness are important, such as food processing equipment and medical devices.

- Aluminum is a lightweight and strong metal. It is used in applications where weight is a concern, such as aircraft and aerospace components.

The choice of material for a particular application depends on a number of factors, including the strength, durability, corrosion resistance, and weight requirements. Steel fabrication companies in Florida have the expertise to help you choose the right material for your project.

Equipment used

Equipment used in steel fabrication companies in Florida is critical to the production of high-quality steel structures. CNC machines, welding machines, and painting booths are essential pieces of equipment that enable steel fabricators to create precise, durable, and aesthetically pleasing products.

- CNC machines are computer-controlled machines that can cut, shape, and drill steel with high precision. This equipment is essential for creating complex shapes and components that would be difficult or impossible to produce by hand.

- Welding machines are used to join pieces of steel together. There are different types of welding machines that can be used for different applications, such as MIG welding, TIG welding, and arc welding. Welding is a critical process in steel fabrication, as it ensures that the final product is strong and durable.

- Painting booths are used to apply a protective coating to steel structures. This coating can help to prevent corrosion and rust, and it can also improve the appearance of the final product. Painting booths are an essential piece of equipment for steel fabrication companies that produce products that will be exposed to the elements.

The use of CNC machines, welding machines, and painting booths allows steel fabrication companies in Florida to produce high-quality steel structures that are essential for a variety of industries, including construction, transportation, and manufacturing. These companies play a vital role in the state’s economy, and their products are used in a wide range of applications, from bridges and buildings to ships and airplanes.

Certifications

Certifications are essential for steel fabrication companies in Florida. They demonstrate that a company has the knowledge, skills, and experience to produce high-quality steel structures.

- AWS (American Welding Society) certification is the most widely recognized certification for welders. It ensures that welders have the skills and knowledge to produce high-quality welds.

- AISC (American Institute of Steel Construction) certification is a mark of excellence for steel fabricators. It demonstrates that a company has the ability to produce steel structures that meet the highest standards of safety and quality.

- ISO 9001 is a quality management system certification. It ensures that a company has a quality management system in place that meets the requirements of ISO 9001.

Steel fabrication companies in Florida that have these certifications are more likely to produce high-quality steel structures that are safe and durable. These companies are also more likely to be able to meet the demands of their customers and to deliver projects on time and within budget.

Location

The location of steel fabrication companies in Florida is a major factor in their success. The state’s major cities, such as Jacksonville, Tampa, Orlando, and Miami, are home to a large number of steel fabrication companies. This is because these cities are major centers of construction and manufacturing activity. Steel fabrication companies in these cities are able to easily access the raw materials and skilled labor that they need to produce high-quality steel structures.

In addition, the location of steel fabrication companies in Florida gives them easy access to the state’s transportation network. This allows them to quickly and efficiently ship their products to customers throughout the state and beyond. As a result, steel fabrication companies in Florida are able to compete with companies from other states and countries.

The concentration of steel fabrication companies in Florida’s major cities has a number of benefits for the state’s economy. These companies create jobs and generate tax revenue. They also support the state’s construction and manufacturing industries. In addition, steel fabrication companies in Florida help to create a more sustainable environment by recycling scrap metal and using energy-efficient manufacturing processes.

Key Insights

- The location of steel fabrication companies in Florida is a major factor in their success.

- The state’s major cities are home to a large number of steel fabrication companies.

- Steel fabrication companies in Florida have easy access to the raw materials and skilled labor that they need.

- The location of steel fabrication companies in Florida gives them easy access to the state’s transportation network.

- Steel fabrication companies in Florida create jobs and generate tax revenue.

- Steel fabrication companies in Florida support the state’s construction and manufacturing industries.

- Steel fabrication companies in Florida help to create a more sustainable environment.

Table: Steel fabrication companies in Florida’s major cities

| City | Number of steel fabrication companies |

|---|---|

| Jacksonville | 50 |

| Tampa | 40 |

| Orlando | 30 |

| Miami | 20 |

Size

The steel fabrication industry in Florida is home to a diverse range of companies, from small businesses to large corporations. Each size of company has its own unique advantages and disadvantages, and the best choice for a particular project will depend on a number of factors, including the size and complexity of the project, the budget, and the timeline.

- Small businesses are often more flexible and adaptable than larger companies. They may be able to offer more personalized service and may be more willing to work with customers on a smaller scale. However, small businesses may also have fewer resources and less experience than larger companies.

- Large corporations typically have more resources and experience than small businesses. They may be able to offer a wider range of services and may be able to handle larger and more complex projects. However, large corporations may also be more bureaucratic and less flexible than small businesses.

Ultimately, the best way to choose a steel fabrication company in Florida is to compare the different companies and their services. It is important to consider the size of the company, the experience of the company, the range of services offered, and the cost of the services. By taking all of these factors into account, you can choose a steel fabrication company that is the right fit for your project.

Experience

Experience is a key factor to consider when choosing a steel fabrication company in Florida. Companies with more experience are more likely to have the skills and expertise to produce high-quality steel structures. They are also more likely to be able to meet the demands of their customers and to deliver projects on time and within budget.

-

Years in business

The number of years that a steel fabrication company has been in business is a good indicator of its experience. Companies that have been in business for a long time have had the opportunity to develop their skills and expertise. They are also more likely to have a good reputation in the industry. -

Number of projects completed

The number of projects that a steel fabrication company has completed is another good indicator of its experience. Companies that have completed a large number of projects have had the opportunity to gain experience in a variety of different areas. They are also more likely to have developed efficient processes for managing and completing projects.

When choosing a steel fabrication company in Florida, it is important to consider the company’s experience. Companies with more experience are more likely to be able to produce high-quality steel structures on time and within budget.

Reputation

Reputation is a key factor to consider when choosing a steel fabrication company in Florida. Companies with a good reputation are more likely to produce high-quality steel structures, deliver projects on time and within budget, and provide excellent customer service.

There are a number of ways to assess the reputation of a steel fabrication company. One way is to read customer reviews. Customer reviews can provide valuable insights into the quality of a company’s products and services, as well as their customer service. Another way to assess a company’s reputation is to look at industry awards. Industry awards are given to companies that have demonstrated excellence in their field. Winning industry awards is a sign that a company is respected by its peers and that it is committed to quality.

When choosing a steel fabrication company in Florida, it is important to consider the company’s reputation. Companies with a good reputation are more likely to be able to meet your needs and expectations.

Key Insights

- Reputation is a key factor to consider when choosing a steel fabrication company in Florida.

- Companies with a good reputation are more likely to produce high-quality steel structures, deliver projects on time and within budget, and provide excellent customer service.

- There are a number of ways to assess the reputation of a steel fabrication company, including reading customer reviews and looking at industry awards.

Table: Customer reviews and industry awards for steel fabrication companies in Florida

| Company | Customer reviews | Industry awards |

|---|---|---|

| Company A | 4.5 stars on Google | Winner of the American Institute of Steel Construction’s Excellence in Steel Award |

| Company B | 4 stars on Yelp | Winner of the National Steel Bridge Alliance’s Steel Bridge Award |

| Company C | 3.5 stars on Facebook | Winner of the Florida Steel Fabricators Association’s Safety Award |

Cost

Cost is a key factor to consider when choosing a steel fabrication company in Florida. Companies that offer competitive pricing and discounts for large orders can help you save money on your project. However, it is important to remember that the lowest price is not always the best price. It is important to consider the quality of the products and services offered, as well as the company’s reputation, before making a decision.

-

Competitive pricing

Steel fabrication companies in Florida offer competitive pricing to attract customers and win new business. This is especially important in a competitive market like Florida, where there are a number of steel fabrication companies to choose from. Competitive pricing can help you save money on your project, but it is important to compare prices from multiple companies before making a decision. -

Discounts for large orders

Many steel fabrication companies in Florida offer discounts for large orders. This can be a great way to save money if you are planning to order a large quantity of steel. Discounts for large orders can vary depending on the company and the size of the order. Be sure to ask about discounts when you are getting quotes from different companies.

When choosing a steel fabrication company in Florida, it is important to consider the cost of the products and services offered. Competitive pricing and discounts for large orders can help you save money on your project. However, it is important to remember that the lowest price is not always the best price. It is important to consider the quality of the products and services offered, as well as the company’s reputation, before making a decision.

Quality

Quality is of paramount importance in the steel fabrication industry in Florida. Steel fabrication companies in Florida must adhere to strict industry standards and use high-quality materials to ensure the safety and durability of their products. The use of high-quality materials and adherence to industry standards are essential for producing steel structures that are strong, reliable, and able to withstand the elements.

There are a number of industry standards that steel fabrication companies in Florida must adhere to. These standards cover a wide range of topics, including design, fabrication, and inspection. By adhering to these standards, steel fabrication companies can ensure that their products are safe and meet the needs of their customers.

In addition to adhering to industry standards, steel fabrication companies in Florida must also use high-quality materials. The quality of the materials used in steel fabrication has a significant impact on the strength, durability, and longevity of the final product. Steel fabrication companies in Florida use a variety of high-quality materials, including steel, stainless steel, and aluminum. These materials are chosen for their strength, durability, and resistance to corrosion.

The use of high-quality materials and adherence to industry standards are essential for producing high-quality steel structures. Steel fabrication companies in Florida that are committed to quality produce products that are safe, durable, and able to withstand the elements.

Key Insights

- Quality is of paramount importance in the steel fabrication industry in Florida.

- Steel fabrication companies in Florida must adhere to strict industry standards and use high-quality materials to ensure the safety and durability of their products.

- The use of high-quality materials and adherence to industry standards are essential for producing steel structures that are strong, reliable, and able to withstand the elements.

Table: Quality standards for steel fabrication companies in Florida

| Standard | Description |

|---|---|

| AWS D1.1 | Structural Welding Code Steel |

| AISC 360 | Specification for Structural Steel Buildings |

| ASTM A36 | Standard Specification for Carbon Structural Steel |

Safety

Safety is of utmost importance in the steel fabrication industry in Florida. Steel fabrication companies in Florida are committed to safety and maintaining compliance with OSHA (Occupational Safety and Health Administration) regulations to ensure a safe working environment for their employees and to protect the public. By adhering to OSHA standards and implementing comprehensive safety programs, these companies prioritize the well-being of their workforce and minimize the risk of accidents and injuries.

OSHA compliance involves following strict guidelines and regulations related to workplace safety, including proper handling and storage of materials, use of personal protective equipment (PPE), and regular safety training for employees. Steel fabrication companies in Florida recognize the importance of these regulations and actively implement them to create a safe and healthy work environment. They conduct regular safety inspections, provide ongoing training on hazard identification and risk assessment, and encourage a culture of safety awareness among their employees.

The commitment to safety in steel fabrication companies in Florida extends beyond compliance with OSHA regulations. Many companies go above and beyond the minimum requirements to implement additional safety measures and best practices. They invest in state-of-the-art safety equipment, develop comprehensive safety manuals, and establish safety committees to foster employee involvement in safety initiatives.

The dedication to safety in steel fabrication companies in Florida has a direct impact on the quality of their products and services. A safe working environment leads to increased productivity, reduced downtime due to accidents, and improved overall efficiency. By prioritizing safety, these companies demonstrate their commitment to not only protecting their employees but also delivering high-quality steel structures that meet industry standards and customer expectations.

Key Insights

- Steel fabrication companies in Florida are committed to safety and maintaining compliance with OSHA regulations.

- OSHA compliance involves following strict guidelines and regulations related to workplace safety.

- Many steel fabrication companies in Florida go above and beyond OSHA requirements to implement additional safety measures and best practices.

- The commitment to safety in steel fabrication companies in Florida has a direct impact on the quality of their products and services.

Table: Examples of Safety Measures Implemented by Steel Fabrication Companies in Florida

| Measure | Description |

|---|---|

| Regular safety inspections | Thorough inspections of the workplace to identify and eliminate potential hazards. |

| Comprehensive safety training | Training programs that cover hazard identification, risk assessment, and safe work practices. |

| Use of personal protective equipment (PPE) | Providing and enforcing the use of PPE such as hard hats, safety glasses, and gloves. |

| Safety committees | Employee-led committees that promote safety awareness and involvement. |

| Investment in state-of-the-art safety equipment | Acquiring and utilizing advanced safety equipment such as fall protection systems and automated welding machines. |

Frequently Asked Questions about Steel Fabrication Companies in Florida

Steel fabrication companies in Florida play a vital role in the state’s construction industry, providing essential steel structures for buildings, bridges, and other infrastructure projects. To address common concerns and misconceptions, here are answers to some frequently asked questions:

Question 1: What services do steel fabrication companies in Florida offer?

Answer: Steel fabrication companies in Florida offer a comprehensive range of services, including welding, fabrication, painting, engineering, and installation. These services are essential for creating durable and safe steel structures that meet industry standards and customer requirements.

Question 2: What materials are used by steel fabrication companies in Florida?

Answer: Steel fabrication companies in Florida primarily use steel, stainless steel, and aluminum. Steel is the most common material due to its strength, durability, and affordability. Stainless steel is used in applications where corrosion resistance is crucial, while aluminum is utilized for its lightweight and high strength-to-weight ratio.

Question 3: How do steel fabrication companies in Florida ensure the quality of their products?

Answer: To ensure the highest quality standards, steel fabrication companies in Florida adhere to strict industry regulations and utilize advanced equipment. They employ certified welders, engineers, and quality control professionals to maintain precision and accuracy throughout the fabrication process. Regular inspections and testing are conducted to guarantee the structural integrity and safety of their products.

Question 4: How can I find reputable steel fabrication companies in Florida?

Answer: To identify reputable steel fabrication companies in Florida, consider factors such as experience, certifications, customer reviews, and industry recognition. Look for companies with a proven track record of delivering high-quality projects on time and within budget. Industry certifications, such as AWS and AISC, demonstrate their commitment to quality and adherence to industry standards.

Question 5: What are the advantages of using steel fabrication companies in Florida?

Answer: Utilizing steel fabrication companies in Florida offers numerous advantages. They provide expertise in design, engineering, and fabrication, ensuring that your steel structures meet specific requirements and building codes. Steel fabrication companies can also handle large-scale projects efficiently, saving time and resources. Additionally, they offer cost-effective solutions tailored to your budget and project needs.

Question 6: How do steel fabrication companies in Florida contribute to the state’s economy?

Answer: Steel fabrication companies in Florida are significant contributors to the state’s economy. They create jobs, stimulate economic growth, and support various industries, including construction, transportation, and manufacturing. By providing essential steel structures for infrastructure projects, they help enhance the state’s overall development and prosperity.

Summary: Steel fabrication companies in Florida play a crucial role in the construction industry, offering a wide range of services and utilizing high-quality materials. Their commitment to quality, safety, and customer satisfaction ensures the delivery of durable and reliable steel structures. By partnering with reputable steel fabrication companies, you can benefit from their expertise, cost-effective solutions, and contributions to the state’s economy.

Transition to the next article section: Explore the diverse range of steel fabrication companies in Florida and their capabilities to meet your specific project requirements.

Tips from Steel Fabrication Companies in Florida

To ensure successful steel fabrication projects, consider these valuable tips from experienced steel fabrication companies in Florida:

Tip 1: Define Project Requirements Clearly

Clearly communicate the project’s specifications, including dimensions, material preferences, and performance expectations. This aids in accurate fabrication and prevents costly errors.

Tip 2: Choose a Reputable Fabricator

Research and select a steel fabrication company with a proven track record, industry certifications, and positive customer feedback. Their expertise and quality standards ensure project success.

Tip 3: Plan for Delivery and Installation

Coordinate delivery and installation schedules with the fabricator to minimize delays and ensure a smooth project flow. Plan for necessary equipment, such as cranes or forklifts, for efficient handling.

Tip 4: Consider Cost-Effective Options

Explore cost-saving measures, such as optimizing material usage, employing efficient fabrication techniques, and seeking bulk discounts. Discuss these options with the fabricator to find a balance between cost and quality.

Tip 5: Prioritize Safety

Emphasize workplace safety throughout the project. Ensure compliance with industry regulations, provide adequate protective gear, and implement proper handling procedures to prevent accidents and injuries.

Tip 6: Foster Open Communication

Maintain open communication with the fabricator during all project stages. Promptly address any changes, concerns, or questions to ensure timely resolutions and avoid misunderstandings.

Summary:

By following these tips, you can enhance the success of your steel fabrication project in Florida. Choosing reputable fabricators, planning effectively, prioritizing safety, and fostering communication will lead to high-quality results, cost-effective solutions, and timely project completion.

Conclusion

Steel fabrication companies in Florida are a vital part of the state’s infrastructure, providing the steel structures that are used in buildings, bridges, and other projects. These companies have a wealth of experience and expertise, and they are committed to providing high-quality products and services. By understanding the key aspects of steel fabrication companies in Florida, you can make informed decisions about who to partner with for your next project.

As Florida continues to grow and develop, the demand for steel fabrication services will only increase. Steel fabrication companies in Florida are well-positioned to meet this demand, and they are committed to providing the highest quality products and services to their customers. By working with a reputable steel fabrication company, you can ensure that your project is completed on time, within budget, and to your specifications.