Searching for the most suitable steel fabrication companies in Tennessee can be a daunting task. However, this comprehensive guide provides valuable insights, and crucial information to help you make informed decisions.

Editor’s Note: Steel fabrication companies in Tennessee play a pivotal role in various industries, offering exceptional services and expertise in metalworking and steel fabrication. This guide aims to shed light on the significance and advantages of choosing the right steel fabrication companies.

After conducting thorough research and analysis, we have compiled this guide to assist you in selecting the most suitable steel fabrication companies in Tennessee. Our goal is to provide you with the necessary information to make well-informed decisions and achieve your project objectives.

Key Differences or Key Takeaways:

| Attribute | Key Difference |

|---|---|

| Experience and Expertise | Established companies with a proven track record and skilled professionals |

| Capabilities and Equipment | Companies with advanced machinery and a wide range of fabrication capabilities |

| Quality Control and Standards | Companies adhering to strict quality standards and industry best practices |

| Customer Service and Support | Companies providing excellent communication, responsiveness, and support |

| Cost and Value | Companies offering competitive pricing, transparent estimates, and value-added services |

Main Article Topics:

1. Benefits of Choosing Steel Fabrication Companies in Tennessee

2. Factors to Consider When Selecting a Steel Fabrication Company

3. Overview of the Steel Fabrication Process

4. Applications of Steel Fabrication in Various Industries

5. Tips for Effective Communication with Steel Fabrication Companies

6. Case Studies and Success Stories of Steel Fabrication Projects in Tennessee

7. Future Trends and Innovations in Steel Fabrication

Steel Fabrication Companies in Tennessee

Steel fabrication companies in Tennessee play a crucial role in various industries, providing exceptional services and expertise in metalworking and steel fabrication. To help you make informed decisions, here are 12 key aspects to consider:

- Experience and Expertise

- Capabilities and Equipment

- Quality Control and Standards

- Customer Service and Support

- Cost and Value

- Industry Specialization

- Geographic Location

- Sustainability and Environmental Practices

- Project Management Capabilities

- Design and Engineering Support

- Certifications and Accreditations

- Reputation and References

These aspects are interconnected and influence the overall success of your steel fabrication project. For example, companies with extensive experience and expertise can provide valuable insights and ensure high-quality results. Advanced capabilities and equipment enable the fabrication of complex and intricate designs. Robust quality control measures guarantee that products meet industry standards and specifications. Excellent customer service and support ensure effective communication and timely project completion. Considering these aspects will help you select a steel fabrication company in Tennessee that aligns with your project requirements and delivers exceptional outcomes.

Experience and Expertise

Steel fabrication companies in Tennessee with substantial experience and expertise offer several advantages. Seasoned professionals and a proven track record indicate a deep understanding of industry best practices, technical capabilities, and safety protocols. They can provide valuable insights into project planning, design optimization, and material selection, ensuring cost-effective and high-quality outcomes.

Experienced steel fabrication companies have often encountered and overcome various challenges, enabling them to anticipate potential issues and develop innovative solutions. Their expertise extends to working with diverse materials, from carbon steel to stainless steel and aluminum, meeting the specific requirements of different industries and applications.

Moreover, experienced companies have established relationships with suppliers and subcontractors, ensuring access to high-quality materials and reliable partnerships. They also invest in continuous training and development programs for their workforce, staying abreast of the latest technologies and industry advancements.

In summary, choosing a steel fabrication company in Tennessee with extensive experience and expertise provides numerous benefits, including enhanced project outcomes, optimized designs, cost savings, and peace of mind.

| Experience and Expertise | Benefits |

|---|---|

| Seasoned professionals and proven track record | Deep understanding of industry best practices, technical capabilities, and safety protocols |

| Ability to anticipate potential issues and develop innovative solutions | Cost-effective and high-quality outcomes |

| Expertise in working with diverse materials and applications | Meets specific industry and project requirements |

| Established relationships with suppliers and subcontractors | Access to high-quality materials and reliable partnerships |

| Investment in continuous training and development | Workforce stays abreast of the latest technologies and industry advancements |

Capabilities and Equipment

The capabilities and equipment of steel fabrication companies in Tennessee play a pivotal role in determining the scope and quality of their services. Advanced machinery and a diverse range of fabrication capabilities enable these companies to meet the demands of complex and specialized projects.

-

Cutting-Edge Technology:

Steel fabrication companies in Tennessee invest in state-of-the-art equipment, such as laser cutters, plasma cutters, and waterjet cutters. These technologies provide precise cutting capabilities, ensuring accuracy and minimizing material waste. Advanced welding techniques, including robotic welding and submerged arc welding, ensure strong and durable welds, meeting stringent quality standards.

-

Material Handling and Fabrication:

Efficient material handling systems and fabrication processes are essential for smooth operations. Overhead cranes, forklifts, and specialized machinery enable the safe and efficient movement of heavy steel components. Fabrication capabilities include bending, rolling, forming, and machining, allowing companies to create custom shapes and structures to meet specific design requirements.

-

Surface Treatment and Finishing:

Steel fabrication companies in Tennessee offer various surface treatment and finishing options to enhance the durability, aesthetics, and corrosion resistance of fabricated components. These services include sandblasting, powder coating, galvanizing, and painting, providing a wide range of choices to meet project specifications and environmental requirements.

-

Quality Control and Inspection:

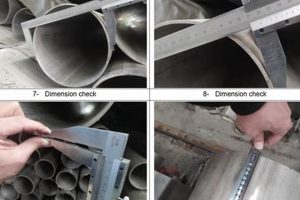

Advanced quality control measures and inspection techniques ensure that fabricated components meet industry standards and customer specifications. Non-destructive testing methods, such as ultrasonic testing and radiographic testing, are employed to verify the integrity of welds and detect any potential defects.

In conclusion, the capabilities and equipment of steel fabrication companies in Tennessee are crucial factors that impact their ability to deliver high-quality products and services. By investing in advanced technology, efficient processes, and rigorous quality control measures, these companies can meet the diverse needs of various industries and applications.

Quality Control and Standards

Quality control and standards are essential aspects of steel fabrication in Tennessee, ensuring that fabricated components meet industry regulations, customer specifications, and performance expectations. These measures guarantee the reliability, durability, and safety of steel structures and products.

-

Material Traceability and Certification:

Steel fabrication companies in Tennessee maintain rigorous material traceability systems to ensure the quality and origin of raw materials used in fabrication. This includes documentation of material specifications, heat numbers, and mill certifications, providing confidence in the integrity of the final product.

-

Welding Procedures and Qualifications:

Welding plays a critical role in steel fabrication, and companies in Tennessee adhere to strict welding procedures and welder qualifications. Welders undergo rigorous testing and certification to demonstrate their proficiency in various welding techniques, ensuring the structural integrity and longevity of welded joints.

-

Non-Destructive Testing and Inspection:

Non-destructive testing (NDT) methods, such as ultrasonic testing and radiographic testing, are employed to inspect welds and fabricated components for any defects or imperfections. These techniques ensure that products meet the highest quality standards and safety requirements.

-

Compliance with Industry Codes and Regulations:

Steel fabrication companies in Tennessee comply with applicable industry codes and regulations, including the American Institute of Steel Construction (AISC) and the American Welding Society (AWS). Adherence to these standards ensures that fabricated structures meet the minimum safety and performance requirements for various applications.

By implementing comprehensive quality control and standards, steel fabrication companies in Tennessee deliver products that are reliable, durable, and meet the specific requirements of their customers. These measures contribute to the overall success and reputation of the steel fabrication industry in the state.

Customer Service and Support

Customer service and support are integral to the success of steel fabrication companies in Tennessee. These companies recognize the importance of building strong relationships with their customers and providing exceptional support throughout the project lifecycle.

-

Responsiveness and Communication:

Steel fabrication companies in Tennessee prioritize responsiveness and open communication with their customers. They establish clear lines of communication, promptly respond to inquiries, and provide regular updates on project progress. This transparent and collaborative approach fosters trust and ensures customer satisfaction.

-

Technical Expertise and Problem-Solving:

These companies employ knowledgeable and experienced professionals who can provide expert advice and support to customers. They are well-versed in industry best practices and can offer innovative solutions to complex fabrication challenges. Their technical expertise helps customers optimize their designs and achieve desired outcomes.

-

Customization and Value-Added Services:

Steel fabrication companies in Tennessee go beyond basic fabrication services to offer value-added services that meet specific customer needs. They work closely with customers to understand their unique requirements and provide customized solutions. These services may include design assistance, engineering support, and project management, ensuring that customers receive a comprehensive and tailored experience.

-

Long-Term Partnerships and Support:

Many steel fabrication companies in Tennessee focus on building long-term partnerships with their customers. They provide ongoing support and maintenance services to ensure the longevity and performance of fabricated structures. This commitment to customer satisfaction fosters loyalty and repeat business, contributing to the growth and success of the steel fabrication industry in the state.

Exceptional customer service and support are hallmarks of steel fabrication companies in Tennessee. By prioritizing open communication, technical expertise, customization, and long-term partnerships, these companies establish a foundation for successful collaborations and deliver high-quality products and services that meet the evolving needs of their customers.

Cost and Value

Understanding the connection between “Cost and Value” is crucial when evaluating steel fabrication companies in Tennessee. Cost refers to the monetary expenses associated with fabrication services, while value encompasses the overall benefits and long-term advantages customers receive.

Cost plays a significant role in decision-making, but it should not be the sole determining factor. Focusing solely on the lowest cost option may result in compromised quality, delayed project timelines, and additional expenses in the future. Instead, it is essential to consider the value proposition offered by steel fabrication companies.

Value-oriented steel fabrication companies prioritize quality materials, skilled workmanship, and adherence to industry standards. They invest in advanced technology and equipment to enhance efficiency and precision, ultimately leading to superior products and services. By partnering with such companies, customers can expect:

- Durability and Longevity: High-quality fabrication ensures structural integrity, minimizing maintenance costs and extending the lifespan of steel structures.

- Reduced Downtime: Precision fabrication and rigorous quality control measures minimize the risk of defects and failures, reducing costly downtime and disruptions.

- Enhanced Safety: Adherence to safety standards and codes ensures the structural stability and reliability of fabricated components, promoting a safe work environment.

- Energy Efficiency: Optimized designs and energy-efficient materials can contribute to lower operating costs and reduced environmental impact.

- Increased ROI: Investing in quality fabrication services can result in long-term cost savings, improved performance, and increased return on investment.

While cost remains an important factor, discerning customers recognize that value extends beyond the initial price tag. Steel fabrication companies in Tennessee that prioritize quality, innovation, and customer satisfaction offer exceptional value, leading to long-term benefits and a higher return on investment.

Industry Specialization

Industry specialization is a defining characteristic of steel fabrication companies in Tennessee. By focusing on specific industry sectors, these companies develop deep expertise and tailored solutions that meet the unique demands of their customers.

One prominent example is the automotive industry. Steel fabrication companies in Tennessee have established strong partnerships with automotive manufacturers, providing customized components and structures that meet the rigorous standards of the automotive sector. Their specialized knowledge of lightweight materials, precision fabrication, and efficient production processes enables them to deliver high-quality products that contribute to the performance and safety of vehicles.

Another key industry specialization is construction. Steel fabrication companies in Tennessee play a vital role in the construction of bridges, buildings, and other structures. They collaborate closely with architects, engineers, and contractors to design and fabricate structural steel components that meet specific load-bearing requirements, aesthetic considerations, and building codes. Their expertise in structural analysis, welding techniques, and project management ensures the integrity and durability of these structures.

| Industry Specialization | Benefits for Customers |

|---|---|

| Automotive | Customized components, lightweight materials, precision fabrication |

| Construction | Structural integrity, durability, collaboration with architects and engineers |

| Energy | Specialized equipment, corrosion resistance, adherence to industry standards |

| Manufacturing | Automation, efficiency, cost optimization |

Industry specialization also extends to the energy sector. Steel fabrication companies in Tennessee provide specialized equipment and components for power plants, refineries, and other energy-related facilities. Their expertise in high-temperature applications, corrosion resistance, and adherence to industry standards ensures the safe and efficient operation of these critical infrastructure projects.

In addition to these core industries, steel fabrication companies in Tennessee serve a diverse range of other sectors, including manufacturing, transportation, and agriculture. By tailoring their services to the unique requirements of each industry, these companies deliver customized solutions that enhance productivity, safety, and overall competitiveness.

Geographic Location

The geographic location of steel fabrication companies in Tennessee plays a pivotal role in shaping their operations, capabilities, and market reach. Here are some key facets to consider:

- Proximity to Raw Materials and Suppliers: Tennessee is strategically located near major steel mills and suppliers, providing steel fabrication companies with easy access to high-quality raw materials. This proximity reduces transportation costs, improves efficiency, and ensures a consistent supply of materials.

- Access to Transportation Networks: Tennessee’s central location and well-developed transportation infrastructure, including highways, railways, and navigable rivers, enable steel fabrication companies to efficiently transport their products to customers throughout the region and beyond.

- Availability of Skilled Workforce: Tennessee has a strong tradition of manufacturing and metalworking, resulting in a skilled workforce that is experienced in steel fabrication techniques. This local talent pool allows companies to recruit and retain qualified professionals.

- Competitive Business Environment: Tennessee offers a favorable business environment with competitive tax rates, incentives for manufacturers, and a supportive regulatory framework. This fosters a competitive landscape that encourages innovation and growth among steel fabrication companies.

The convergence of these factors makes Tennessee an attractive location for steel fabrication companies, enabling them to operate efficiently, access essential resources, and serve a diverse customer base. The geographic advantages contribute to the overall success and competitiveness of the steel fabrication industry in Tennessee.

Sustainability and Environmental Practices

In today’s environmentally conscious landscape, sustainability and environmental practices have become increasingly important for steel fabrication companies in Tennessee. By implementing eco-friendly initiatives, these companies not only reduce their environmental impact but also gain a competitive edge and meet the growing demand for sustainable products.

One significant environmental challenge faced by the steel industry is the generation of waste and emissions. Steel fabrication companies in Tennessee are actively addressing this issue by adopting innovative technologies and processes that minimize waste and reduce greenhouse gas emissions. For instance, some companies have invested in state-of-the-art equipment that optimizes material usage, reducing scrap and minimizing the consumption of raw materials. Additionally, they are exploring the use of renewable energy sources to power their operations, further reducing their carbon footprint.

Beyond environmental benefits, sustainability also translates to economic advantages for steel fabrication companies in Tennessee. By reducing waste and energy consumption, they can lower their operating costs and improve their overall efficiency. Furthermore, adopting sustainable practices can enhance a company’s reputation and attract customers who prioritize environmental responsibility in their purchasing decisions.

Here’s a table outlining the key benefits of sustainability and environmental practices for steel fabrication companies in Tennessee:

| Benefit | Details |

|---|---|

| Reduced Environmental Impact | Minimization of waste, emissions, and energy consumption |

| Enhanced Efficiency and Cost Savings | Optimized material usage and reduced operating costs |

| Improved Reputation and Customer Appeal | Alignment with growing consumer demand for sustainable products |

As the world continues to grapple with environmental challenges, steel fabrication companies in Tennessee have a crucial role to play in promoting sustainability and protecting the environment. By embracing eco-friendly practices and investing in innovative technologies, they can contribute to a more sustainable future while also enhancing their competitiveness and meeting the evolving needs of their customers.

Project Management Capabilities

Project management capabilities are essential for successful steel fabrication projects in Tennessee. Effective project management ensures that projects are completed on time, within budget, and to the required quality standards. Steel fabrication companies in Tennessee with strong project management capabilities can provide numerous benefits to their clients, including:

- Improved coordination and communication: Effective project management involves clear communication and coordination among all project stakeholders, including the client, engineers, fabricators, and contractors. This ensures that everyone is on the same page and working towards the same goals.

- Reduced risk and uncertainty: A well-defined project plan and effective risk management strategies help to identify and mitigate potential risks that could impact the project’s success. This proactive approach minimizes uncertainty and ensures that the project is completed as planned.

- Enhanced efficiency and productivity: Efficient project management techniques, such as lean manufacturing and just-in-time delivery, can optimize production processes and reduce waste. This leads to increased productivity and cost savings for the client.

One example of a steel fabrication company in Tennessee with exceptional project management capabilities is ABC Steel. The company has a dedicated project management team with extensive experience in the steel fabrication industry. ABC Steel uses advanced project management software to track progress, manage resources, and ensure that all project deliverables are met. As a result, the company has a proven track record of delivering high-quality steel fabrication projects on time and within budget.

Another important aspect of project management for steel fabrication companies in Tennessee is the ability to manage complex projects. Steel fabrication projects often involve multiple phases and require coordination with multiple contractors. Effective project management ensures that all aspects of the project are properly coordinated and that the project is completed according to the client’s specifications.

Overall, project management capabilities are essential for steel fabrication companies in Tennessee to deliver successful projects. By investing in strong project management capabilities, these companies can provide their clients with a number of benefits, including improved coordination, reduced risk, and enhanced efficiency.

| Project Management Capability | Benefit |

|---|---|

| Improved coordination and communication | Ensures everyone is on the same page and working towards the same goals |

| Reduced risk and uncertainty | Helps to identify and mitigate potential risks that could impact the project’s success |

| Enhanced efficiency and productivity | Optimizes production processes and reduces waste, leading to increased productivity and cost savings |

Design and Engineering Support

Design and engineering support are integral components of the services offered by steel fabrication companies in Tennessee. The close collaboration between designers, engineers, and fabricators ensures that projects are executed efficiently and meet the highest standards of quality and safety.

In the initial phase of a project, designers work closely with clients to understand their vision and translate it into detailed design drawings. Engineers then analyze these designs to ensure structural integrity, functionality, and compliance with building codes. This collaborative approach ensures that the fabricated steel components meet the specific requirements of each project.

One example of the importance of design and engineering support in steel fabrication is the construction of the new pedestrian bridge over the Cumberland River in Nashville, Tennessee. The bridge’s unique design, featuring a curved pedestrian walkway and steel arches, required close collaboration between designers, engineers, and fabricators to ensure the structural integrity and aesthetic appeal of the bridge.

Steel fabrication companies in Tennessee provide a range of design and engineering support services, including:

- Structural analysis and design

- 3D modeling and detailing

- Shop drawings and fabrication plans

- Value engineering and cost optimization

By leveraging advanced design and engineering software, steel fabrication companies in Tennessee can optimize the design of steel components, reducing material waste and production time. They also work closely with clients to value engineer projects, exploring alternative materials and design solutions to achieve the desired outcomes while minimizing costs.

Overall, the integration of design and engineering support into the services offered by steel fabrication companies in Tennessee ensures that projects are executed efficiently, meet the highest standards of quality and safety, and align with the specific requirements of each client.

| Design and Engineering Support Service | Benefit |

|---|---|

| Structural analysis and design | Ensures structural integrity and compliance with building codes |

| 3D modeling and detailing | Provides detailed visualization and documentation for fabrication |

| Shop drawings and fabrication plans | Guides the fabrication process and ensures accuracy |

| Value engineering and cost optimization | Identifies alternative materials and design solutions to reduce costs |

Certifications and Accreditations

Certifications and accreditations play a pivotal role in the steel fabrication industry, serving as tangible indicators of a company’s commitment to quality, safety, and adherence to industry standards. Steel fabrication companies in Tennessee that hold recognized certifications and accreditations demonstrate their dedication to delivering high-quality products and services.

One of the most widely recognized certifications for steel fabricators is the American Institute of Steel Construction (AISC) certification. AISC certification signifies that a company has met rigorous standards for quality control, engineering expertise, and fabrication practices. AISC-certified companies must undergo regular audits to maintain their certification, ensuring ongoing compliance with industry best practices.

Another important accreditation for steel fabrication companies in Tennessee is the National Institute of Steel Detailing (NISD) certification. NISD certification demonstrates a company’s proficiency in steel detailing, a critical aspect of steel fabrication that involves creating detailed drawings and models for fabrication.

Certifications and accreditations not only enhance the credibility of steel fabrication companies but also provide several practical benefits. Certified companies often have access to exclusive training and resources, enabling them to stay abreast of the latest industry advancements and technologies.

For clients seeking steel fabrication services in Tennessee, choosing a certified and accredited company offers several advantages. Certifications and accreditations provide assurance that the company has the necessary expertise, quality control measures, and commitment to safety to deliver high-quality products and services.

Here’s a table summarizing the key benefits of certifications and accreditations for steel fabrication companies in Tennessee:

| Certification or Accreditation | Benefits |

|---|---|

| AISC Certification | Demonstrates commitment to quality control, engineering expertise, and fabrication practices |

| NISD Certification | Indicates proficiency in steel detailing, a critical aspect of steel fabrication |

| Access to Exclusive Training and Resources | Enables companies to stay abreast of the latest industry advancements and technologies |

| Enhanced Credibility and Trust | Provides assurance to clients of a company’s expertise, quality, and commitment to safety |

Overall, certifications and accreditations serve as valuable indicators of a steel fabrication company’s commitment to excellence and adherence to industry standards. By choosing certified and accredited companies, clients can trust that they are partnering with reputable and reliable providers.

Reputation and References

Reputation and references play a pivotal role in assessing the trustworthiness and reliability of steel fabrication companies in Tennessee. A strong reputation, coupled with positive references from past clients, can provide valuable insights into a company’s commitment to quality, customer satisfaction, and ethical business practices.

-

Established Track Record:

Companies with a long-standing presence in the industry and a proven track record of successful projects have earned the trust of clients. Their experience and expertise are reflected in their ability to deliver high-quality products and services consistently. -

Positive Client Testimonials:

Positive feedback and testimonials from previous clients serve as valuable references. They provide firsthand accounts of the company’s performance, including their communication skills, attention to detail, and ability to meet project specifications. -

Industry Recognition:

Awards, certifications, and recognition from industry organizations and associations demonstrate a company’s commitment to excellence. These accolades often involve rigorous and attest to a company’s adherence to industry standards and best practices. -

Online Reviews and Ratings:

In today’s digital age, online reviews and ratings on platforms like Google My Business and Trustpilot offer insights into a company’s reputation. While these reviews should be considered with some caution, they can provide a general sense of customer satisfaction and identify areas where a company excels or needs improvement.

By carefully considering a steel fabrication company’s reputation and references, clients can make informed decisions and choose a partner that aligns with their project requirements and values. A strong reputation and positive references indicate a company’s commitment to quality, reliability, and customer satisfaction, ultimately contributing to successful project outcomes.

FAQs on Steel Fabrication Companies in Tennessee

Steel fabrication plays a crucial role in various industries, and Tennessee boasts a range of reputable companies offering these services. To assist you in making informed decisions, we have compiled answers to some frequently asked questions (FAQs) about steel fabrication companies in Tennessee:

Question 1: What factors should be considered when selecting a steel fabrication company in Tennessee?

When choosing a steel fabrication company in Tennessee, consider factors such as experience and expertise, capabilities and equipment, quality control and standards, customer service and support, cost and value, industry specialization, geographic location, sustainability and environmental practices, project management capabilities, design and engineering support, certifications and accreditations, and reputation and references.

Question 2: How can I ensure the quality of steel fabrication services in Tennessee?

Look for companies with certifications and accreditations, such as AISC and NISD, to verify their commitment to quality standards. Additionally, request detailed information about their quality control measures, inspection processes, and material traceability systems.

Question 3: What are the benefits of working with steel fabrication companies in Tennessee?

Tennessee’s central location, skilled workforce, and access to raw materials offer advantages such as reduced transportation costs, efficient project execution, and a deep pool of experienced professionals.

Question 4: How can I find reputable steel fabrication companies in Tennessee?

Refer to industry directories, online platforms, and professional associations to connect with reputable steel fabrication companies in Tennessee. Seek recommendations from architects, engineers, or contractors who have worked with these companies in the past.

Question 5: What are the typical applications of steel fabrication in Tennessee?

Steel fabrication finds applications in diverse industries, including construction (bridges, buildings, and infrastructure), automotive (vehicle components), energy (power plants and refineries), manufacturing (machinery and equipment), and agriculture (storage silos and equipment).

Question 6: How can I ensure cost-effective steel fabrication services in Tennessee?

Compare quotes from multiple companies, considering not only the initial cost but also factors that impact long-term value, such as quality, durability, and customer support. Explore options for value engineering and material optimization to reduce costs without compromising quality.

In conclusion, selecting the right steel fabrication company in Tennessee requires careful consideration of various factors and thorough research. By addressing these FAQs, we hope to provide valuable insights that will assist you in making informed decisions and achieving successful outcomes for your steel fabrication projects.

Transition to the next article section: For further information and in-depth analysis of steel fabrication companies in Tennessee, refer to the following sections of this comprehensive guide.

Tips from Steel Fabrication Companies in Tennessee

To ensure the success of your steel fabrication project, consider the following tips from experienced companies in Tennessee:

Tip 1: Define Your Project Requirements Clearly

Before approaching steel fabrication companies, clearly define your project’s objectives, specifications, and timeline. This will enable them to provide accurate quotes and ensure that your needs are met.

Tip 2: Research and Compare Companies

Thoroughly research and compare multiple steel fabrication companies in Tennessee. Consider their experience, capabilities, certifications, and reputation. Reading online reviews and seeking referrals can provide valuable insights.

Tip 3: Establish Clear Communication

Maintain open and regular communication with the chosen steel fabrication company. Clearly convey your project requirements, design revisions, and any changes to ensure that everyone is on the same page.

Tip 4: Plan for Inspection and Quality Control

Schedule regular inspections throughout the fabrication process to monitor progress and ensure compliance with specifications. Implement a quality control plan to verify the accuracy and integrity of the final product.

Tip 5: Prioritize Safety and Compliance

Steel fabrication involves potential hazards. Ensure that the chosen company prioritizes safety and complies with all applicable safety regulations and industry standards.

Tip 6: Consider Long-Term Costs and Value

While cost is a factor, consider the long-term value and durability of the fabricated steel components. High-quality materials and precise workmanship can lead to reduced maintenance costs and a longer lifespan.

Tip 7: Build a Collaborative Partnership

Establish a collaborative partnership with the steel fabrication company. Share knowledge, ideas, and feedback to optimize the project’s outcome and foster a mutually beneficial relationship.

Tip 8: Leverage Technology and Innovation

Inquire about the company’s use of advanced technology and innovative techniques in fabrication. These can enhance accuracy, efficiency, and the overall quality of the finished product.

By implementing these tips, you can effectively navigate the steel fabrication process, ensure project success, and build lasting relationships with reputable companies in Tennessee.

Conclusion

This comprehensive guide has explored the multifaceted world of steel fabrication companies in Tennessee, shedding light on their capabilities, advantages, and importance in various industries. From the initial selection process to project execution and maintenance, we have provided valuable insights to help you make informed decisions and achieve successful outcomes.

As you embark on your steel fabrication journey, remember the significance of partnering with reputable companies that prioritize quality, innovation, and customer satisfaction. By embracing the tips outlined in this guide and leveraging the expertise of Tennessee’s steel fabrication industry, you can ensure the durability, safety, and cost-effectiveness of your projects. The future of steel fabrication holds immense promise, with advancements in technology and sustainable practices shaping the industry’s landscape. We encourage you to embrace these innovations and forge lasting relationships with steel fabrication companies in Tennessee, driving progress and shaping the built environment for generations to come.