What is a steel fabrication company? A steel fabrication company is a business that specializes in the fabrication of steel structures. These companies use a variety of techniques to shape and form steel into the desired product, including cutting, bending, welding, and assembling.

Editor’s Note: Steel fabrication is an essential process in the construction of many different types of structures, including buildings, bridges, and ships. Steel fabrication companies play a vital role in the construction industry, and their work is essential for the safety and stability of our infrastructure.

In this guide, we will explore the different aspects of steel fabrication companies, including their services, benefits, and how to choose the right company for your needs. We will also provide some tips on how to get the most out of your steel fabrication project.

Key Differences or Key Takeaways

| Characteristic | Steel Fabrication Company |

|---|---|

| Services | Steel fabrication companies offer a wide range of services, including cutting, bending, welding, and assembling. |

| Benefits | Steel fabrication companies can provide a number of benefits, including cost savings, time savings, and quality control. |

| How to Choose | When choosing a steel fabrication company, it is important to consider factors such as experience, reputation, and price. |

Transition to Main Article Topics

The following are some of the main topics that we will cover in this guide:

- What is a steel fabrication company?

- The different services offered by steel fabrication companies

- The benefits of using a steel fabrication company

- How to choose the right steel fabrication company for your needs

- Tips on how to get the most out of your steel fabrication project

We hope that this guide will help you learn more about steel fabrication companies and how they can benefit your business. If you have any questions, please feel free to contact us.

Steel Fabrication Company

Steel fabrication companies play a vital role in the construction industry, providing a range of services that are essential for the safety and stability of our infrastructure. Here are 9 key aspects of steel fabrication companies:

- Services: Cutting, bending, welding, assembling

- Benefits: Cost savings, time savings, quality control

- Experience: Years in business, track record of successful projects

- Reputation: Reviews and testimonials from past clients

- Price: Competitive pricing, transparent cost structure

- Equipment: State-of-the-art equipment for precision fabrication

- Materials: High-quality steel materials, certified and tested

- Safety: Commitment to safety, compliance with industry standards

- Sustainability: Environmentally friendly practices, waste reduction

These key aspects are all important factors to consider when choosing a steel fabrication company for your project. By carefully considering each of these factors, you can ensure that you choose a company that will provide you with the high-quality products and services that you need.

For example, if you are looking for a steel fabrication company to work on a large-scale construction project, you will want to choose a company with a proven track record of success on similar projects. You will also want to make sure that the company has the experience and expertise to meet your specific needs.

No matter what your steel fabrication needs may be, it is important to choose a company that you can trust to deliver high-quality products and services. By considering the key aspects outlined above, you can choose a steel fabrication company that will help you achieve your project goals.

Services

Steel fabrication companies offer a wide range of services, including cutting, bending, welding, and assembling. These services are essential for the production of steel structures, which are used in a variety of applications, including buildings, bridges, and ships.

-

Cutting

Cutting is the process of removing material from a piece of steel. This can be done using a variety of methods, including sawing, shearing, and plasma cutting. Cutting is used to create the basic shapes of steel structures.

-

Bending

Bending is the process of shaping a piece of steel by applying force. This can be done using a variety of methods, including press brakes and bending rolls. Bending is used to create curves and angles in steel structures.

-

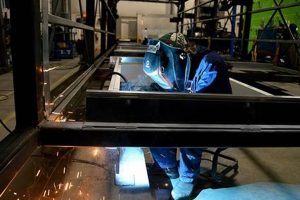

Welding

Welding is the process of joining two pieces of steel together by melting the metal at the joint. This can be done using a variety of methods, including arc welding and MIG welding. Welding is used to create strong and durable joints in steel structures.

-

Assembling

Assembling is the process of putting together the individual components of a steel structure. This can be done using a variety of methods, including bolting and riveting. Assembling is used to create the final product, which is then ready to be used in its intended application.

These four services are essential for the production of steel structures. Steel fabrication companies use these services to create a wide range of products, from simple beams to complex bridges. By understanding these services, you can better understand the role of steel fabrication companies in the construction industry.

Benefits

Steel fabrication companies offer a number of benefits to their customers, including cost savings, time savings, and quality control. These benefits are essential for businesses that need to produce high-quality steel structures in a timely and cost-effective manner.

-

Cost savings

Steel fabrication companies can help businesses save money in a number of ways. First, they can purchase steel in bulk, which gives them a lower price per ton. Second, they have the experience and expertise to optimize the cutting, bending, and welding processes, which reduces waste and saves time. Third, they can often provide value-added services, such as painting and galvanizing, which can save businesses the time and expense of outsourcing these services.

-

Time savings

Steel fabrication companies can help businesses save time in a number of ways. First, they can provide fast turnaround times on orders. Second, they can work with businesses to develop a production schedule that meets their specific needs. Third, they can deliver the finished products directly to the job site, which saves businesses the time and expense of transporting the products themselves.

-

Quality control

Steel fabrication companies have the experience and expertise to ensure that their products meet the highest quality standards. They use state-of-the-art equipment and follow strict quality control procedures to ensure that their products are accurate, durable, and safe. In addition, they can provide documentation and certification to prove that their products meet the required standards.

These are just a few of the benefits that steel fabrication companies can offer their customers. By partnering with a steel fabrication company, businesses can save money, time, and ensure that they are getting the highest quality products.

Experience

When choosing a steel fabrication company, it is important to consider their experience. This includes the number of years they have been in business and their track record of successful projects. An experienced company is more likely to have the expertise and knowledge to complete your project safely and efficiently.

-

Years in business

The number of years a steel fabrication company has been in business is a good indicator of their experience. A company that has been in business for many years has had the opportunity to develop a strong track record and build a reputation for quality work.

-

Track record of successful projects

A steel fabrication company’s track record of successful projects is another important factor to consider. This includes the types of projects they have completed, the size and complexity of the projects, and the satisfaction of their past clients. A company with a strong track record is more likely to be able to complete your project successfully.

When evaluating a steel fabrication company’s experience, it is also important to consider the specific needs of your project. For example, if you are working on a large or complex project, you will want to choose a company with experience in similar projects. You should also consider the company’s safety record and their commitment to quality.

By considering the experience of a steel fabrication company, you can increase the likelihood of choosing a company that will complete your project safely, efficiently, and to your satisfaction.

Reputation

Reputation is everything in the steel fabrication industry. When potential customers are looking for a company to work with, they will often read reviews and testimonials from past clients to get an idea of the company’s quality of work, customer service, and overall reliability. A company with a strong reputation is more likely to attract new customers and grow its business.

There are a number of things that steel fabrication companies can do to build a strong reputation. First, they should focus on providing high-quality products and services. This means using high-quality materials, employing skilled workers, and following strict quality control procedures. Second, they should provide excellent customer service. This means being responsive to customer inquiries, resolving problems quickly and efficiently, and going the extra mile to meet customer needs. Third, they should get involved in their community and give back to those in need. This shows that they are a caring and responsible company that is invested in the well-being of others.

Here are some examples of how steel fabrication companies have used their reputation to grow their business:

- A steel fabrication company in California used its reputation for high-quality work to win a contract to build the new Bay Bridge. The company’s reputation for quality and reliability gave the customer confidence that the project would be completed on time and within budget.

- A steel fabrication company in Texas used its reputation for excellent customer service to win a contract to build a new stadium for the Dallas Cowboys. The company’s commitment to customer satisfaction gave the customer confidence that they would be taken care of throughout the project.

- A steel fabrication company in Florida used its reputation for community involvement to win a contract to build a new hospital for the local community. The company’s commitment to giving back to the community showed the customer that they were a caring and responsible company.

These are just a few examples of how steel fabrication companies have used their reputation to grow their business. By focusing on providing high-quality products and services, providing excellent customer service, and getting involved in their community, steel fabrication companies can build a strong reputation that will help them attract new customers and grow their business.

Table: The Importance of Reputation for Steel Fabrication Companies

| Importance | Benefits |

|---|---|

| Attracts new customers | A good reputation can help steel fabrication companies attract new customers by giving them confidence that they will receive high-quality products and services. |

| Increases sales | A good reputation can help steel fabrication companies increase sales by making it easier to close deals with new and existing customers. |

| Builds trust | A good reputation can help steel fabrication companies build trust with their customers by showing that they are a reliable and trustworthy company. |

| Improves customer satisfaction | A good reputation can help steel fabrication companies improve customer satisfaction by ensuring that customers are happy with the products and services they receive. |

| Increases employee morale | A good reputation can help steel fabrication companies increase employee morale by showing employees that they are proud to work for a company that is respected in the industry. |

Price

Price is an important factor to consider when choosing a steel fabrication company. You want to make sure that you are getting a fair price for the products and services you need. However, price is not the only thing to consider. You also want to make sure that the company you choose has a transparent cost structure. This means that they are upfront about their pricing and that there are no hidden costs.

A competitive pricing structure can help you save money on your steel fabrication project. When companies are competing for your business, they are more likely to offer lower prices. A transparent cost structure can help you avoid unexpected costs. When you know exactly what you are paying for, you can budget accordingly and avoid any surprises.

Here are some examples of how competitive pricing and a transparent cost structure can benefit you:

- You can save money on your steel fabrication project.

- You can avoid unexpected costs.

- You can budget more effectively.

- You can make more informed decisions about your steel fabrication project.

When choosing a steel fabrication company, be sure to compare prices from multiple companies. Also, be sure to ask about their cost structure. This will help you make an informed decision and choose the company that is right for you.

Table: The Importance of Price and Cost Structure for Steel Fabrication Companies

| Importance | Benefits |

|---|---|

| Competitive pricing | Can help you save money on your steel fabrication project. |

| Transparent cost structure | Can help you avoid unexpected costs and budget more effectively. |

Equipment

Steel fabrication companies rely on state-of-the-art equipment to achieve precision fabrication. This equipment includes computer-controlled cutting machines, welding machines, and bending machines. These machines are essential for producing high-quality steel products that meet the exacting specifications of customers.

Computer-controlled cutting machines use lasers or plasma to cut steel with precision. This allows steel fabrication companies to create complex shapes and designs with accuracy and repeatability. Welding machines use advanced technology to create strong and durable welds. Bending machines use hydraulic or electric power to bend steel into complex shapes.

The use of state-of-the-art equipment provides several benefits to steel fabrication companies. First, it allows them to produce high-quality products that meet the exacting specifications of customers. Second, it helps to improve productivity and efficiency. Third, it reduces the risk of errors and accidents.

Here are some examples of how state-of-the-art equipment is used in steel fabrication:

- Computer-controlled cutting machines are used to create complex shapes and designs in steel. This is used in the production of a variety of products, including automotive parts, construction materials, and medical devices.

- Welding machines are used to join steel components together. This is used in the production of a variety of products, including bridges, buildings, and ships.

- Bending machines are used to bend steel into complex shapes. This is used in the production of a variety of products, including furniture, appliances, and automotive parts.

Steel fabrication companies that invest in state-of-the-art equipment are able to produce high-quality products that meet the exacting specifications of customers. This helps them to win new business and grow their market share.

Table: The Importance of State-of-the-Art Equipment for Steel Fabrication Companies

| Importance | Benefits |

|---|---|

| Precision fabrication | State-of-the-art equipment allows steel fabrication companies to produce high-quality products that meet the exacting specifications of customers. |

| Productivity and efficiency | State-of-the-art equipment helps to improve productivity and efficiency by automating tasks and reducing the risk of errors. |

| Safety | State-of-the-art equipment can help to reduce the risk of accidents by automating tasks and providing safety features. |

Materials

The quality of the materials used in steel fabrication has a significant impact on the quality of the finished product. Steel fabrication companies that use high-quality steel materials, certified and tested to meet industry standards, are able to produce products that are strong, durable, and safe.

There are many different grades of steel, each with its own unique properties. Steel fabrication companies must carefully select the right grade of steel for each project, based on the specific requirements of the application. For example, a steel fabrication company that is producing structural steel for a bridge will need to use a grade of steel that is strong enough to withstand the of traffic and the elements.

In addition to the grade of steel, the quality of the steel is also important. Steel that is free of defects, such as cracks, inclusions, and voids, will produce a stronger and more durable product. Steel fabrication companies should purchase their steel from reputable suppliers who can provide certification and testing to ensure that the steel meets the required standards.

Using high-quality steel materials is essential for steel fabrication companies that want to produce products that are safe, durable, and meet the expectations of their customers.

Table: The Importance of High-Quality Steel Materials for Steel Fabrication Companies

| Importance | Benefits |

|---|---|

| Strength | High-quality steel materials are stronger and more durable than lower-quality materials. This is important for steel fabrication companies that are producing products that will be subjected to heavy loads or harsh conditions. |

| Durability | High-quality steel materials are more resistant to corrosion and wear than lower-quality materials. This is important for steel fabrication companies that are producing products that will be exposed to the elements or to harsh chemicals. |

| Safety | High-quality steel materials are less likely to fail than lower-quality materials. This is important for steel fabrication companies that are producing products that will be used in safety-critical applications. |

Safety

Safety is of paramount importance in the steel fabrication industry. Steel fabrication companies must be committed to safety and must comply with all applicable industry standards. This is essential for protecting workers, the public, and the environment.

There are many potential hazards in steel fabrication, including:

- Exposure to hazardous chemicals

- Working with heavy machinery

- Working at heights

- Exposure to loud noise

- Exposure to welding fumes

Steel fabrication companies must have a comprehensive safety program in place to address these hazards. This program should include:

- A written safety plan

- Regular safety training for employees

- Regular safety inspections

- A system for reporting and investigating accidents

- A system for tracking and maintaining safety records

Steel fabrication companies must also comply with all applicable industry standards. These standards are designed to protect workers and the public from the hazards of steel fabrication.

The most important industry standard for steel fabrication is the Occupational Safety and Health Administration (OSHA) standard 1910.252. This standard sets forth the minimum requirements for the safe handling and use of steel in construction and general industry.

Steel fabrication companies that comply with OSHA 1910.252 and other applicable industry standards are more likely to have a safe workplace and to avoid accidents and injuries.

Table: The Importance of Safety in Steel Fabrication

| Importance | Benefits |

|---|---|

| Protects workers | A safe workplace reduces the risk of accidents and injuries, which can save lives and prevent lost time from work. |

| Protects the public | Steel fabrication companies that comply with safety standards help to protect the public from the hazards of steel fabrication, such as exposure to hazardous chemicals and welding fumes. |

| Protects the environment | Steel fabrication companies that comply with safety standards help to protect the environment from pollution, such as air and water pollution. |

| Reduces costs | A safe workplace can reduce costs for steel fabrication companies by reducing the risk of accidents and injuries, which can lead to lower insurance premiums and workers’ compensation costs. |

Sustainability

Sustainability is a growing concern for businesses of all types, and steel fabrication companies are no exception. Steel fabrication can be a resource-intensive process, but there are a number of ways to reduce the environmental impact of this industry.

-

Recycling and waste reduction

One of the most important ways to reduce the environmental impact of steel fabrication is to recycle scrap metal. Steel is one of the most recycled materials in the world, and recycling scrap metal helps to conserve natural resources and reduce landfill waste. Steel fabrication companies can also reduce waste by using efficient cutting and welding techniques, and by reusing materials whenever possible.

-

Energy efficiency

Steel fabrication can be an energy-intensive process, but there are a number of ways to improve energy efficiency in this industry. Steel fabrication companies can use energy-efficient equipment, such as LED lighting and variable-speed drives. They can also improve the efficiency of their processes by optimizing cutting and welding parameters.

-

Pollution prevention

Steel fabrication can also generate air and water pollution. Steel fabrication companies can reduce their environmental impact by using pollution control equipment, such as scrubbers and filters. They can also reduce their water usage by using water-efficient technologies, such as closed-loop cooling systems.

-

Sustainable materials

Steel fabrication companies can also reduce their environmental impact by using sustainable materials. For example, they can use recycled steel, or they can use steel that is produced using renewable energy sources. Steel fabrication companies can also use materials that are certified by environmental organizations, such as the Forest Stewardship Council (FSC).

By adopting sustainable practices, steel fabrication companies can reduce their environmental impact and improve their bottom line. Sustainable practices can help steel fabrication companies to save money on energy and materials, and they can also help to attract customers who are looking for environmentally friendly products and services.

FAQs about Steel Fabrication Companies

Steel fabrication companies play a vital role in the construction industry, providing essential services for the production of steel structures used in a wide range of applications. Here are answers to some frequently asked questions about steel fabrication companies:

Question 1: What services do steel fabrication companies offer?

Steel fabrication companies offer a range of services, including cutting, bending, welding, and assembling. These services are essential for the production of steel structures, which are used in a variety of applications, including buildings, bridges, and ships.

Question 2: What are the benefits of using a steel fabrication company?

There are many benefits to using a steel fabrication company, including cost savings, time savings, and quality control. Steel fabrication companies can purchase steel in bulk, which gives them a lower price per ton. They also have the experience and expertise to optimize the cutting, bending, and welding processes, which reduces waste and saves time. In addition, steel fabrication companies can provide value-added services, such as painting and galvanizing, which can save businesses the time and expense of outsourcing these services.

Question 3: How do I choose the right steel fabrication company for my project?

When choosing a steel fabrication company, it is important to consider factors such as experience, reputation, price, and equipment. You should also make sure that the company you choose has a good safety record and is committed to quality.

Question 4: What are some of the challenges facing steel fabrication companies?

Steel fabrication companies face a number of challenges, including the rising cost of steel, the shortage of skilled workers, and the increasing demand for sustainable products. However, steel fabrication companies are adapting to these challenges by investing in new technologies, training their employees, and developing new products and services.

Question 5: What is the future of the steel fabrication industry?

The future of the steel fabrication industry is bright. Steel is a strong, durable, and versatile material that is essential for the construction of a wide range of structures. As the demand for steel continues to grow, steel fabrication companies will continue to play a vital role in the construction industry.

Summary: Steel fabrication companies provide essential services for the production of steel structures used in a wide range of applications. By understanding the services offered by steel fabrication companies, the benefits of using a steel fabrication company, and the factors to consider when choosing a steel fabrication company, you can make informed decisions about your steel fabrication needs.

Transition to the next article section: For more information on steel fabrication companies, please see our article on “How to Choose the Right Steel Fabrication Company for Your Project”.

Tips for Working with Steel Fabrication Companies

Steel fabrication companies can provide a range of services essential for the construction industry. However, choosing the right steel fabrication company for your project is important. Here are five tips to help you make the right decision:

Tip 1: Define your project requirements. Before contacting steel fabrication companies, it is important to define your project requirements. This includes the type of steel structure you need, the dimensions of the structure, and the timeline for the project. Having a clear understanding of your project requirements will help you communicate your needs to steel fabrication companies and get accurate quotes.

Tip 2: Research steel fabrication companies. Once you have defined your project requirements, you can start researching steel fabrication companies. There are a number of online directories and review websites that can help you find steel fabrication companies in your area. When researching steel fabrication companies, it is important to consider factors such as experience, reputation, and price.

Tip 3: Get multiple quotes. Once you have shortlisted a few steel fabrication companies, it is important to get multiple quotes. This will help you compare prices and services and choose the best steel fabrication company for your project. When getting quotes, be sure to provide each steel fabrication company with the same information about your project.

Tip 4: Visit the steel fabrication company. Before making a decision, it is a good idea to visit the steel fabrication company and see their facilities. This will give you a chance to meet the staff, see the equipment they use, and get a sense of the company’s culture. Visiting the steel fabrication company will also help you assess their safety record and commitment to quality.

Tip 5: Make a decision. After you have visited the steel fabrication companies and gathered all the information you need, you can make a decision. When making your decision, it is important to consider factors such as price, experience, reputation, and safety. You should also consider the company’s ability to meet your project requirements and timeline.

Summary: By following these tips, you can increase your chances of choosing the right steel fabrication company for your project. Steel fabrication companies can provide a range of services essential for the construction industry, so it is important to do your research and choose a company that meets your specific needs.

Transition to the article’s conclusion: For more information on steel fabrication companies, please see our article on “How to Choose the Right Steel Fabrication Company for Your Project”.

Conclusion

Steel fabrication companies play a vital role in the construction industry, providing essential services for the production of steel structures used in a wide range of applications. From buildings and bridges to ships and offshore platforms, steel structures are essential for the modern world.

When choosing a steel fabrication company, it is important to consider factors such as experience, reputation, price, and quality. By doing your research and choosing the right steel fabrication company, you can ensure that your project is completed safely, on time, and within budget.