When embarking on a new construction project, selecting the right steel fabrication company is crucial. Steel fabrication companies specialize in the creation of steel structures and components used in the construction industry, and choosing a reputable and experienced company can significantly impact the success of your project.

Editor’s Note: Understanding the role of steel fabrication companies in new builds is essential for ensuring the structural integrity, safety, and durability of your project.

To assist you in making an informed decision, we have conducted thorough research and analysis, compiling this comprehensive guide to steel fabrication companies for new builds. This guide will provide you with the necessary information to evaluate and select the best company for your project.

Key Differences: As you compare different steel fabrication companies, consider the following key factors:

| Factor | Importance |

|---|---|

| Experience and Expertise | A company with a proven track record and specialized knowledge in new build projects. |

| Fabrication Capabilities | The ability to handle complex designs, meet tight tolerances, and adhere to industry standards. |

| Project Management | Effective communication, coordination, and adherence to project timelines. |

| Quality Control | Rigorous quality control measures to ensure the accuracy and durability of fabricated components. |

| Customer Service | Responsive and supportive throughout the project, addressing any concerns or changes promptly. |

Transition to Main Article Topics: In the following sections, we will delve deeper into the various aspects of steel fabrication companies for new builds, including:

- The benefits of using steel in new builds

- How to choose the right steel fabrication company

- The different types of steel fabrication services

- The cost of steel fabrication

- Tips for working with a steel fabrication company

Steel Fabrication Company for New Builds

Selecting the right steel fabrication company for your new build project is crucial to ensure the structural integrity, safety, and durability of your building. Here are ten key aspects to consider:

- Experience: A proven track record in new build projects.

- Expertise: Specialized knowledge in steel fabrication techniques.

- Capabilities: Ability to handle complex designs and meet tight tolerances.

- Project Management: Effective communication and coordination throughout the project.

- Quality Control: Rigorous quality control measures to ensure accuracy and durability.

- Customer Service: Responsive and supportive throughout the project lifecycle.

- Cost: Competitive pricing and transparent cost breakdowns.

- Timeline: Adherence to project timelines and timely delivery.

- Safety: Commitment to workplace safety and compliance with industry regulations.

- Sustainability: Use of sustainable materials and environmentally friendly practices.

These aspects are interconnected and play a vital role in the success of your new build project. For instance, a company with extensive experience and expertise can provide valuable insights into design optimization and cost-saving measures. Effective project management ensures smooth coordination between the fabrication team and other contractors, preventing delays and ensuring timely completion. Moreover, a commitment to quality control guarantees the accuracy and durability of the fabricated steel components, ensuring the structural integrity of your building for years to come.

Experience

In the context of steel fabrication for new builds, experience plays a pivotal role in ensuring the success and quality of a project. A steel fabrication company with a proven track record in new build projects brings a wealth of knowledge and expertise to the table, leading to numerous benefits:

- Expertise in new build challenges: Experienced companies have encountered and overcome the unique challenges associated with new build projects, such as complex designs, tight deadlines, and stringent building codes.

- Optimized design solutions: With experience comes the ability to identify and implement innovative design solutions that enhance the structural integrity, functionality, and aesthetics of the building.

- Cost-effective solutions: Experienced companies can leverage their knowledge to identify cost-saving measures without compromising quality, helping clients optimize their budgets.

- Streamlined project management: A proven track record indicates a company’s ability to manage projects efficiently, ensuring timely delivery and minimizing disruptions.

Ultimately, choosing a steel fabrication company with experience in new build projects provides peace of mind, knowing that the company has the expertise and capabilities to deliver a successful outcome.

Expertise

In the context of steel fabrication for new builds, specialized knowledge in steel fabrication techniques is a critical component that underpins the success and quality of a project. Expertise in this domain encompasses a deep understanding of various steel fabrication processes, material properties, and industry standards. Here’s how specialized knowledge contributes to the success of steel fabrication companies in new builds:

- Structural integrity: Expertise in steel fabrication techniques ensures that structural components are designed and fabricated to meet or exceed building codes and industry standards, ensuring the overall structural integrity of the new build.

- Design optimization: Specialized knowledge enables steel fabricators to optimize designs for efficiency, cost-effectiveness, and aesthetics. They can suggest alternative fabrication methods or material choices that enhance the overall performance of the building.

- Quality control: Expertise in fabrication techniques allows companies to implement rigorous quality control measures throughout the fabrication process. This ensures that components meet specified tolerances and quality standards, minimizing the risk of defects or failures.

- Innovation and problem-solving: Specialized knowledge empowers steel fabricators to embrace innovation and find creative solutions to complex design challenges. They can develop custom fabrication techniques or adapt existing ones to meet unique project requirements.

Ultimately, choosing a steel fabrication company with specialized knowledge in steel fabrication techniques provides assurance that the company has the expertise to deliver high-quality, safe, and durable steel components that meet the specific demands of new build projects.

Table: Expertise in Steel Fabrication Techniques and Its Impact on New Builds

| Expertise Area | Impact on New Builds |

|---|---|

| Structural design | Ensures structural integrity and compliance with building codes |

| Material selection and optimization | Optimizes cost, efficiency, and performance of steel components |

| Fabrication processes | Controls quality, accuracy, and efficiency of fabrication |

| Quality control and testing | Guarantees adherence to standards and minimizes defects |

| Innovation and problem-solving | Addresses complex design challenges and improves overall project outcomes |

Capabilities

In the realm of steel fabrication for new builds, the ability to handle complex designs and meet tight tolerances is a critical capability that sets successful steel fabrication companies apart. This capability encompasses various aspects that are essential for delivering high-quality and structurally sound steel components:

- Advanced Design Engineering: The ability to interpret complex architectural and engineering designs and translate them into detailed fabrication plans. This involves expertise in structural analysis, material properties, and fabrication techniques.

- Precision Fabrication Equipment: State-of-the-art fabrication equipment, such as CNC machines, laser cutters, and robotic welders, ensures precise cutting, bending, and welding of steel components, meeting the tightest tolerances.

- Skilled Craftsmanship: A team of experienced and skilled craftsmen who possess the expertise to execute complex fabrication tasks with precision and attention to detail.

- Quality Control and Inspection: Rigorous quality control measures and non-destructive testing techniques to verify the accuracy and integrity of fabricated components before they leave the facility.

Steel fabrication companies that possess these capabilities can confidently undertake new build projects that involve intricate designs, demanding specifications, and tight deadlines. Their ability to handle complex geometries, such as curved beams, tapered columns, and custom architectural features, enables them to contribute to the realization of innovative and visually striking buildings.

Project Management

In the context of steel fabrication for new builds, effective project management is paramount to the successful execution and timely completion of the project. It encompasses a wide range of responsibilities that ensure seamless communication, coordination, and collaboration among all stakeholders involved in the project.

Effective project management in steel fabrication involves:

- Clear Communication: Establishing and maintaining open lines of communication among the steel fabricator, contractors, architects, engineers, and the client. This ensures that everyone involved is informed, aligned, and working towards the same goals.

- Detailed Planning: Developing a comprehensive project plan that outlines the scope of work, timelines, milestones, and deliverables. This plan serves as a roadmap for the project and helps keep everyone on track.

- Regular Coordination: Holding regular project meetings, site visits, and progress reviews to monitor the progress, identify potential issues, and make necessary adjustments.

- Change Management: Anticipating and managing changes that may arise during the project. This involves assessing the impact of changes, communicating them effectively, and updating the project plan accordingly.

- Risk Mitigation: Identifying and evaluating potential risks to the project and developing strategies to mitigate or eliminate them. This proactive approach helps prevent delays, cost overruns, and other disruptions.

By implementing effective project management practices, steel fabrication companies can streamline the new build process, reduce uncertainties, and deliver high-quality results that meet the client’s expectations.

Table: Benefits of Effective Project Management in Steel Fabrication for New Builds

| Benefit | Impact on New Builds |

|---|---|

| Improved communication and coordination | Reduced errors, delays, and disputes |

| Clear project planning | Increased efficiency and productivity |

| Regular progress monitoring | Early identification and resolution of issues |

| Effective change management | Minimized disruption and cost overruns |

| Proactive risk mitigation | Enhanced project success and client satisfaction |

Quality Control

In the context of steel fabrication for new builds, rigorous quality control measures are essential to ensure the accuracy and durability of fabricated steel components. These measures encompass various aspects that contribute to the overall quality and reliability of the final product.

- Material Inspection: Steel fabrication companies implement stringent material inspection procedures to verify the quality and properties of incoming raw materials. This includes testing for chemical composition, mechanical properties, and surface finish to ensure that the materials meet the specified standards.

- Fabrication Process Control: Throughout the fabrication process, companies adhere to documented quality control procedures that govern each step, from cutting and bending to welding and assembly. This ensures that all fabrication operations are performed according to industry best practices and meet the required tolerances.

- Non-Destructive Testing: Steel fabricators employ non-destructive testing (NDT) techniques to evaluate the integrity of fabricated components without compromising their structural properties. NDT methods, such as ultrasonic testing and radiography, detect hidden defects, ensuring the reliability and safety of the final product.

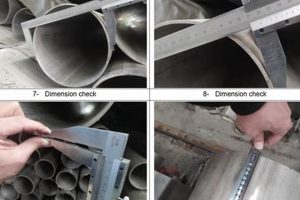

- Dimensional Verification: Fabricated components are subjected to rigorous dimensional verification to ensure they meet the specified dimensions and tolerances. This involves using precision measuring equipment and templates to check the accuracy of angles, lengths, and other critical dimensions.

By implementing comprehensive quality control measures, steel fabrication companies for new builds can guarantee the accuracy and durability of their products, contributing to the structural integrity, safety, and longevity of the buildings they support.

Customer Service

In the context of steel fabrication for new builds, customer service plays a pivotal role in ensuring a successful and satisfactory project outcome. Responsive and supportive customer service is not merely an added value but an integral component of a reliable steel fabrication company for new builds.

Throughout the project lifecycle, effective customer service manifests in several ways:

- Prompt Communication: Steel fabrication companies with exceptional customer service are highly responsive to inquiries, requests, and concerns raised by clients. They establish clear communication channels and respond promptly to emails, phone calls, and site visits.

- Proactive Updates: Proactive customer service involves updates on project progress, potential delays, and any changes that may impact the project timeline or deliverables. This transparency builds trust and keeps clients informed.

- Site Support: Responsive customer service extends to providing on-site support during the installation and construction phases. Representatives from the steel fabrication company can be present to address any queries, resolve issues, and ensure smooth integration of fabricated components.

- Post-Project Support: Customer service does not end with project completion. Reputable steel fabrication companies offer ongoing support, addressing any queries or concerns that may arise after the building is occupied.

The practical significance of responsive and supportive customer service in steel fabrication for new builds cannot be overstated. It fosters a collaborative relationship between the steel fabricator and the client, leading to better decision-making, timely problem-solving, and overall project success.

Table: Benefits of Responsive and Supportive Customer Service in Steel Fabrication for New Builds

| Benefit | Impact on New Builds |

|---|---|

| Enhanced communication and collaboration | Reduced misunderstandings and delays |

| Proactive issue resolution | Minimized disruptions and cost overruns |

| Increased client satisfaction | Positive reputation and repeat business |

| Improved project outcomes | High-quality buildings that meet client expectations |

Cost

In the realm of steel fabrication for new builds, competitive pricing and transparent cost breakdowns are not merely desirable attributes but essential components that contribute to project success and client satisfaction.

Competitive pricing ensures that steel fabrication companies offer their services at market-competitive rates, allowing clients to secure high-quality steel components without breaking the bank. Transparent cost breakdowns, on the other hand, provide clients with a clear understanding of the cost structure, including materials, labor, fabrication processes, and any additional expenses.

The significance of competitive pricing and transparent cost breakdowns in steel fabrication for new builds is multifaceted:

- Informed Decision-Making: Transparent cost breakdowns empower clients to make informed decisions about their projects. They can compare costs from different steel fabrication companies, evaluate the value proposition, and select the best option that aligns with their budget and requirements.

- Cost Control: Competitive pricing helps clients control project costs and avoid unexpected expenses. By selecting a steel fabrication company that offers competitive rates, clients can optimize their budgets and allocate resources more effectively.

- Trust and Confidence: Transparent cost breakdowns foster trust and confidence between steel fabrication companies and their clients. When clients have a clear understanding of the cost structure, they are more likely to trust the company’s pricing and business practices.

- Long-Term Relationships: Competitive pricing and transparent cost breakdowns can lay the foundation for long-term relationships between steel fabrication companies and their clients. By providing value and building trust, steel fabricators can secure repeat business and establish themselves as reliable partners for future projects.

In summary, competitive pricing and transparent cost breakdowns are essential aspects of steel fabrication for new builds. They enable informed decision-making, cost control, trust-building, and the fostering of long-term relationships, ultimately contributing to successful project outcomes and client satisfaction.

Table: Practical Implications of Competitive Pricing and Transparent Cost Breakdowns in Steel Fabrication for New Builds

| Implication | Impact on New Builds |

|---|---|

| Informed decision-making | Empowers clients to make optimal choices |

| Cost control | Prevents budget overruns and optimizes resource allocation |

| Trust and confidence | Strengthens relationships between clients and steel fabricators |

| Long-term relationships | Leads to repeat business and project continuity |

Timeline

In the context of steel fabrication for new builds, strict adherence to project timelines and timely delivery are crucial for ensuring a successful outcome. Delays in steel fabrication can have a domino effect, impacting other aspects of the construction process and potentially leading to costly consequences.

- Planning and Coordination: Steel fabrication companies must meticulously plan and coordinate their work to meet project deadlines. This involves effective communication with the general contractor, architects, and engineers to ensure that all parties are aligned and working towards the same timeline.

- Resource Management: To ensure timely delivery, steel fabricators must manage their resources efficiently. This includes optimizing production schedules, ensuring adequate staffing, and maintaining a steady supply of materials.

- Quality Control: Maintaining high standards of quality while meeting deadlines requires a delicate balance. Steel fabricators must implement robust quality control measures without compromising the speed of production.

- Contingency Planning: Unforeseen circumstances can arise during any construction project. Steel fabrication companies must have contingency plans in place to mitigate delays caused by factors such as weather conditions or material shortages.

By adhering to project timelines and delivering on time, steel fabrication companies for new builds contribute to the overall success of the construction project. They ensure that the building is completed according to schedule, allowing owners and tenants to occupy the space as planned. Timely delivery also minimizes the financial impact of delays, reduces stress for all parties involved, and maintains a positive reputation for the steel fabrication company.

Safety

In the realm of steel fabrication for new builds, a commitment to workplace safety and compliance with industry regulations is not just an ethical obligation but a fundamental pillar of successful operations.

Steel fabrication processes involve the use of heavy machinery, hazardous materials, and complex procedures. Without stringent safety measures, workers face significant risks of accidents, injuries, and even fatalities. Steel fabrication companies that prioritize safety create a work environment where employees feel protected and valued, leading to increased productivity and reduced absenteeism.

Compliance with industry regulations is equally crucial. Adhering to established safety standards ensures that steel fabrication companies operate within legal parameters and minimize the risk of accidents and legal liabilities. Moreover, it demonstrates a commitment to ethical practices and responsible business conduct.

The practical significance of workplace safety in steel fabrication for new builds cannot be overstated. Safe working conditions contribute to:

- Reduced accidents and injuries: Stringent safety measures prevent accidents, minimizing downtime, medical expenses, and potential legal claims.

- Increased productivity: Employees who feel safe and protected are more focused and productive, leading to higher output and efficiency.

- Enhanced reputation: A strong safety record enhances a steel fabrication company’s reputation, attracting skilled workers and fostering trust with clients.

- Legal compliance: Compliance with industry regulations protects companies from legal liabilities and fines associated with workplace accidents.

In summary, a commitment to workplace safety and compliance with industry regulations is an indispensable aspect of steel fabrication for new builds. It safeguards employees, ensures legal compliance, enhances productivity, and ultimately contributes to the success and reputation of steel fabrication companies.

| Safety Measure | Practical Significance |

|---|---|

| Hazard identification and risk assessment | Proactively identifies and mitigates potential hazards |

| Personal protective equipment (PPE) | Protects workers from physical and chemical hazards |

| Regular safety training and certification | Ensures workers are knowledgeable and skilled in safe work practices |

| Incident reporting and investigation | Facilitates continuous improvement and prevents future incidents |

| Emergency response plans | Ensures a swift and coordinated response to emergencies |

Sustainability

In the context of steel fabrication for new builds, the use of sustainable materials and environmentally friendly practices is not merely a trend but a fundamental aspect that contributes to the overall sustainability and eco-friendliness of the construction industry.

Sustainable steel fabrication practices encompass a range of initiatives that minimize environmental impact and promote resource conservation. These practices include:

- Recycled Steel: Utilizing recycled steel in fabrication processes reduces the need for raw material extraction and energy consumption, conserving natural resources and lowering carbon emissions.

- Energy-Efficient Technologies: Implementing energy-efficient technologies in fabrication facilities, such as LED lighting and optimized machinery, reduces energy consumption and greenhouse gas emissions.

- Waste Reduction: Steel fabricators can adopt waste reduction strategies, such as recycling scrap metal and optimizing cutting patterns, to minimize waste generation and promote circularity.

- Sustainable Coatings: Using sustainable coatings and finishes for fabricated steel components reduces the release of harmful chemicals and promotes the use of eco-friendly materials.

The practical significance of sustainability in steel fabrication for new builds is multifaceted:

- Environmental Protection: Sustainable practices protect the environment by reducing pollution, conserving resources, and mitigating climate change.

- Cost Savings: Energy-efficient technologies and waste reduction initiatives can lead to reduced operating costs for steel fabricators.

- Enhanced Reputation: Embracing sustainability enhances a steel fabrication company’s reputation and attracts environmentally conscious clients.

- Compliance with Regulations: Adhering to environmental regulations is essential for steel fabricators to operate responsibly and avoid legal liabilities.

In conclusion, the use of sustainable materials and environmentally friendly practices in steel fabrication for new builds is a crucial aspect that contributes to the industry’s environmental stewardship, cost-effectiveness, and overall sustainability. Steel fabrication companies that prioritize sustainability demonstrate their commitment to responsible business practices and help create a more sustainable built environment.

| Sustainable Practice | Environmental Benefit |

|---|---|

| Recycled Steel | Reduces raw material extraction and energy consumption |

| Energy-Efficient Technologies | Lowers energy consumption and greenhouse gas emissions |

| Waste Reduction | Minimizes waste generation and promotes circularity |

| Sustainable Coatings | Reduces the release of harmful chemicals |

Frequently Asked Questions about Steel Fabrication for New Builds

This FAQ section addresses common inquiries and misconceptions surrounding steel fabrication for new builds, providing informative answers to guide decision-making and enhance understanding.

Question 1: What are the advantages of using steel in new build construction?

Steel offers numerous benefits for new builds, including exceptional strength-to-weight ratio, durability, fire resistance, and versatility in design. It enables the creation of structures that are both robust and aesthetically pleasing.

Question 2: How do I choose a reputable steel fabrication company for my new build project?

Selecting a reputable steel fabrication company is crucial for project success. Consider factors such as experience, expertise, fabrication capabilities, project management skills, quality control measures, customer service, cost, and adherence to timelines.

Question 3: What is the typical cost range for steel fabrication in new builds?

Steel fabrication costs vary depending on the project’s complexity, material selection, fabrication processes, and location. It is advisable to obtain quotes from multiple steel fabrication companies to compare pricing and ensure competitiveness.

Question 4: How can I ensure the quality of steel fabrication for my new build?

To ensure quality, look for steel fabrication companies with rigorous quality control measures, certifications, and a proven track record of delivering high-quality products. On-site inspections during fabrication can provide additional assurance.

Question 5: What are the environmental considerations for steel fabrication in new builds?

Sustainable steel fabrication practices can minimize environmental impact. Choose companies that utilize recycled steel, implement energy-efficient technologies, and adopt waste reduction strategies.

Question 6: How do I ensure timely delivery of steel components for my new build project?

To avoid delays, work with steel fabrication companies that have a proven ability to adhere to project timelines. Clear communication, effective coordination, and contingency planning are essential for ensuring timely delivery.

Summary: Understanding the intricacies of steel fabrication for new builds empowers individuals to make informed decisions, choose reputable companies, and ensure the success of their construction projects.

Transition to the Next Article Section: Exploring the latest advancements in steel fabrication technologies and their impact on new build construction.

Tips for Selecting a Steel Fabrication Company for New Builds

Choosing the right steel fabrication company is crucial for the success of any new build project. Here are some tips to help you make an informed decision:

Tip 1: Consider Experience and Expertise

Look for companies with a proven track record in new build projects. They should have the knowledge and expertise to handle the unique challenges of these projects, such as complex designs, tight deadlines, and stringent building codes.

Tip 2: Evaluate Fabrication Capabilities

Ensure that the company has the equipment and capabilities to fabricate the steel components required for your project. This includes the ability to handle large and complex structures, as well as specialized processes such as welding, cutting, and forming.

Tip 3: Assess Project Management Skills

Effective project management is essential for delivering a successful project on time and within budget. Look for companies with a structured project management process, clear communication channels, and a commitment to meeting deadlines.

Tip 4: Prioritize Quality Control

The quality of the steel fabrication will directly impact the safety and durability of your building. Choose companies with rigorous quality control measures in place, including inspections, testing, and documentation.

Tip 5: Consider Customer Service

Responsive and supportive customer service is essential throughout the project. Look for companies that are easily accessible, communicate proactively, and are willing to address any concerns or changes promptly.

Summary: By following these tips, you can increase your chances of selecting a steel fabrication company that will deliver high-quality products, meet your project deadlines, and provide excellent customer service.

Transition to the article’s conclusion: With the right steel fabrication partner, you can ensure the structural integrity, safety, and durability of your new build project.

Conclusion

Throughout this article, we have explored the critical role of steel fabrication companies in the success of new build projects. By choosing a reputable and experienced company, you can ensure the structural integrity, safety, and durability of your building.

When selecting a steel fabrication company, consider factors such as experience, expertise, fabrication capabilities, project management skills, quality control measures, customer service, and cost. By carefully evaluating these aspects, you can find a partner who will deliver high-quality products, meet your project deadlines, and provide excellent customer support.

Partnering with the right steel fabrication company is an investment in the long-term success of your new build project. Their expertise and commitment to quality will ensure that your building stands strong and serves its purpose for years to come.