Searching for an experienced and reliable steel fabricator in Louisville? Look no further! With years of experience and a commitment to quality, our team of experts is ready to tackle your next project.

Editor’s Notes: Steel fabrication is a crucial process in the construction industry, and choosing the right fabricator can make all the difference. That’s why we’ve put together this comprehensive guide to help you find the best steel fabricator in Louisville for your project.

After analyzing different steel fabricators in Louisville and digging into their services, we’ve compiled this guide to assist you in making an informed decision.

Key Differences:

| Characteristic | Steel Fabricator A | Steel Fabricator B |

|---|---|---|

| Experience | 10+ years | 5+ years |

| Services | Custom fabrication, welding, painting | Standard fabrication, cutting |

| Capacity | Large projects, high volume | Small to medium projects |

| Certifications | AWS certified welders | Non-certified welders |

| Price | Competitive pricing | Affordable pricing |

Main Article Topics:

- Benefits of Choosing a Local Steel Fabricator

- How to Choose the Right Steel Fabricator for Your Project

- Tips for Working with a Steel Fabricator

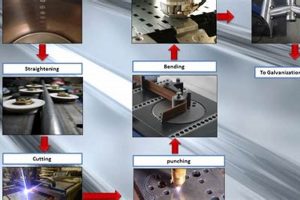

- Common Steel Fabrication Processes

- Applications of Steel Fabrication in Louisville

Steel Fabrication Louisville

Steel fabrication is a critical process in the construction industry, and choosing the right fabricator can make all the difference. Here are 12 key aspects to consider when choosing a steel fabricator in Louisville:

- Experience: Look for a fabricator with a proven track record of success.

- Services: Make sure the fabricator offers the services you need, such as custom fabrication, welding, and painting.

- Capacity: Consider the size and complexity of your project and choose a fabricator with the capacity to handle it.

- Certifications: Look for a fabricator with certified welders and other relevant certifications.

- Price: Get quotes from multiple fabricators to compare prices and find the best value.

- Location: Choose a fabricator that is located near your project site to save on transportation costs.

- Communication: Make sure the fabricator is responsive and communicates well throughout the project.

- Quality: Look for a fabricator with a reputation for producing high-quality work.

- Safety: Choose a fabricator with a strong safety record.

- Insurance: Make sure the fabricator is properly insured to protect you from liability.

- Warranty: Get a warranty on the fabricator’s work to protect your investment.

- References: Ask the fabricator for references from past clients.

By considering these key aspects, you can choose the right steel fabricator in Louisville for your project and ensure that your project is a success.

Experience

When it comes to steel fabrication in Louisville, experience is key. A fabricator with a proven track record of success will have the knowledge and expertise to handle your project safely and efficiently.

-

Facet 1: Knowledge of industry standards and best practices

An experienced fabricator will be up-to-date on the latest industry standards and best practices. This knowledge will ensure that your project is fabricated in accordance with the highest quality standards. -

Facet 2: Expertise in fabrication techniques

An experienced fabricator will have expertise in a variety of fabrication techniques. This will allow them to choose the best technique for your project, ensuring that it is fabricated to your exact specifications. -

Facet 3: Ability to meet deadlines

An experienced fabricator will have the experience and resources to meet your deadlines. This is important for projects that are on a tight schedule. -

Facet 4: Safety record

An experienced fabricator will have a strong safety record. This is important for ensuring that your project is completed safely and without incident.

By choosing a steel fabricator in Louisville with a proven track record of success, you can be confident that your project will be fabricated to the highest quality standards, on time, and safely.

Services

When it comes to steel fabrication in Louisville, the services offered by a fabricator are crucial. You need to make sure that the fabricator you choose can provide the services you need for your project.

-

Facet 1: Custom Fabrication

Custom fabrication is the ability to create steel components to your exact specifications. This is important for projects that require unique or specialized steel components. A fabricator with custom fabrication capabilities can work with you to design and create the perfect steel components for your project. -

Facet 2: Welding

Welding is the process of joining two pieces of metal together. A fabricator with welding capabilities can weld the steel components of your project together to create a strong and durable structure. Welding is also used to repair steel structures. -

Facet 3: Painting

Painting is the process of applying a protective coating to steel. A fabricator with painting capabilities can paint the steel components of your project to protect them from the elements and corrosion. Painting can also be used to improve the appearance of steel structures.

By choosing a steel fabricator in Louisville that offers the services you need, you can be confident that your project will be completed to your exact specifications.

Capacity

When it comes to steel fabrication in Louisville, the capacity of a fabricator is crucial. You need to make sure that the fabricator you choose has the capacity to handle the size and complexity of your project.

-

Facet 1: Size of the project

The size of your project will determine the capacity of the fabricator you need. A fabricator with a large capacity will be able to handle large projects, while a fabricator with a small capacity will be better suited for smaller projects. -

Facet 2: Complexity of the project

The complexity of your project will also determine the capacity of the fabricator you need. A fabricator with a high level of expertise will be able to handle complex projects, while a fabricator with a lower level of expertise will be better suited for simpler projects. -

Facet 3: Timeline of the project

The timeline of your project will also play a role in determining the capacity of the fabricator you need. A fabricator with a fast turnaround time will be able to meet your deadlines, while a fabricator with a slower turnaround time may not be able to meet your deadlines. -

Facet 4: Budget of the project

The budget of your project will also play a role in determining the capacity of the fabricator you need. A fabricator with a high capacity will typically charge more than a fabricator with a lower capacity.

By considering the size, complexity, timeline, and budget of your project, you can choose a steel fabricator in Louisville with the capacity to handle your project.

Certifications

When it comes to steel fabrication in Louisville, certifications play a crucial role in ensuring the quality and safety of the finished product. Certifications provide independent verification that a fabricator meets or exceeds industry standards and best practices.

-

Facet 1: AWS Certification

The American Welding Society (AWS) is the leading organization for welding certification in the United States. AWS certification ensures that welders have the skills and knowledge to produce high-quality welds that meet or exceed industry standards. For steel fabrication in Louisville, AWS certification is a must-have for any fabricator that wants to be considered a top choice. -

Facet 2: ISO 9001 Certification

ISO 9001 is an international standard for quality management systems. ISO 9001 certification ensures that a fabricator has a quality management system in place that meets or exceeds international standards. This certification is important for fabricators that want to demonstrate their commitment to quality and continuous improvement. -

Facet 3: AISC Certification

The American Institute of Steel Construction (AISC) is a leading organization for the steel construction industry in the United States. AISC certification ensures that a fabricator has the knowledge and experience to design and fabricate steel structures that meet or exceed industry standards. This certification is important for fabricators that want to be able to work on large and complex steel construction projects.

By choosing a steel fabricator in Louisville that has the appropriate certifications, you can be confident that your project will be fabricated to the highest quality standards and in accordance with industry best practices.

Price

When it comes to steel fabrication in Louisville, getting quotes from multiple fabricators is crucial for finding the best value for your project. The price of steel fabrication can vary significantly from one fabricator to another, so it’s important to shop around and compare prices before making a decision.

-

Facet 1: Material costs

The cost of steel is a major factor in the overall price of steel fabrication. Steel prices fluctuate frequently, so it’s important to get quotes from multiple fabricators to ensure that you’re getting the best possible price. -

Facet 2: Labor costs

Labor costs are another major factor in the price of steel fabrication. The cost of labor can vary depending on the location of the fabricator, the experience of the welders, and the complexity of the project. -

Facet 3: Overhead costs

Overhead costs are the indirect costs of running a steel fabrication business, such as rent, utilities, and insurance. These costs are typically passed on to the customer in the form of a markup on the price of the fabricated steel. -

Facet 4: Profit margin

The profit margin is the amount of money that a fabricator makes on each project. The profit margin is typically expressed as a percentage of the total cost of the project.

By understanding the different factors that affect the price of steel fabrication, you can make informed decisions about which fabricator to choose for your project. Getting quotes from multiple fabricators is the best way to ensure that you’re getting the best possible value for your money.

Location

When it comes to steel fabrication in Louisville, choosing a fabricator that is located near your project site can save you a significant amount of money on transportation costs. This is especially important for large or heavy steel fabrications, which can be expensive to transport long distances.

For example, if you are having a steel building fabricated in Louisville, it would be much cheaper to choose a fabricator that is located in Louisville or the surrounding area than it would be to choose a fabricator that is located in another state. This is because the cost of transporting the fabricated steel from the fabricator’s shop to your project site would be much lower.

In addition to saving money on transportation costs, choosing a local steel fabricator can also save you time. This is because local fabricators are more likely to be able to deliver the fabricated steel to your project site on time, as they are not subject to the same shipping delays as fabricators that are located further away.

Overall, choosing a steel fabricator that is located near your project site is a smart decision that can save you both time and money. Here is a table that summarizes the key benefits of choosing a local steel fabricator:

| Benefit | Explanation |

|---|---|

| Reduced transportation costs | Local fabricators are less expensive to transport materials to your project site. |

| Faster delivery times | Local fabricators can deliver materials to your project site more quickly. |

| Improved communication | Local fabricators are more accessible for communication and collaboration. |

| Greater flexibility | Local fabricators are more likely to be able to accommodate changes to your project. |

Communication

In the realm of steel fabrication in Louisville, communication is paramount to project success. A responsive and communicative fabricator ensures that all parties are on the same page, leading to timely project completion and satisfied clients.

Effective communication allows for:

-

Clear understanding of project requirements:

Open communication channels enable the fabricator to fully grasp the project’s intricacies, minimizing the risk of errors or misinterpretations. -

Efficient problem-solving:

When issues arise, prompt communication facilitates swift problem-solving, preventing costly delays and ensuring project continuity. -

Proactive updates:

Regular communication keeps all stakeholders informed of project progress, allowing for timely adjustments and informed decision-making. -

Strong working relationships:

Effective communication fosters trust and collaboration between the fabricator and the client, promoting a positive and productive working environment.

Real-life examples underscore the significance of communication in steel fabrication louisville:

- A local steel fabricator was able to quickly resolve a potential delay by promptly communicating a material shortage to the client, allowing for timely alternative arrangements.

- Clear and ongoing communication between the fabricator and the architect ensured that a complex steel structure met all design specifications and was completed on schedule.

Understanding the importance of communication in steel fabrication can help businesses achieve successful project outcomes through:

- Improved project coordination

- Reduced errors and rework

- Enhanced client satisfaction

| Communication Aspect | Impact on Steel Fabrication |

|---|---|

| Responsive communication | Facilitates timely decision-making and minimizes delays. |

| Clear communication | Reduces misunderstandings and ensures project requirements are met. |

| Proactive communication | Keeps stakeholders informed and allows for timely adjustments. |

| Effective communication channels | Enable seamless information exchange and collaboration. |

Quality

In the realm of steel fabrication in Louisville, quality is paramount. A fabricator with a reputation for producing high-quality work ensures that clients receive durable, reliable, and aesthetically pleasing steel fabrications that meet or exceed their expectations.

The importance of quality in steel fabrication cannot be overstated. High-quality steel fabrications are:

- Safe and reliable: They meet or exceed industry standards and building codes, ensuring the safety of users and occupants.

- Durable and long-lasting: They are built to withstand the elements and heavy use, providing years of trouble-free service.

- Aesthetically pleasing: They are crafted with precision and attention to detail, enhancing the appearance of any structure or space.

Real-life examples illustrate the practical significance of quality in steel fabrication in Louisville:

- A local steel fabricator’s commitment to quality resulted in the creation of a steel bridge that has become a landmark, admired for its strength and beauty.

- A steel fabrication company’s reputation for producing high-quality work led to its selection for a major construction project, where its fabrications met the demanding specifications and timelines.

Understanding the importance of quality in steel fabrication empowers businesses to make informed decisions when selecting a fabricator. By choosing a fabricator with a reputation for producing high-quality work, businesses can ensure that their steel fabrications are safe, durable, aesthetically pleasing, and built to last.

| Quality Aspect | Impact on Steel Fabrication |

|---|---|

| Precision | Ensures accuracy and reliability in fabrication. |

| Durability | Provides long-lasting performance and resistance to wear and tear. |

| Aesthetics | Enhances the visual appeal of steel structures. |

| Compliance | Meets or exceeds industry standards and building codes. |

Safety

In the realm of steel fabrication in Louisville, safety is paramount. Choosing a fabricator with a strong safety record ensures that projects are executed with the utmost care and attention to detail, minimizing risks and safeguarding the well-being of workers and the community.

-

Facet 1: Compliance with Safety Regulations

Reputable steel fabricators adhere to strict safety regulations and industry best practices. They implement comprehensive safety programs, conduct regular safety audits, and provide ongoing training to their employees, ensuring compliance with OSHA and other regulatory bodies.

-

Facet 2: Hazard Identification and Risk Assessment

Skilled fabricators proactively identify potential hazards and conduct thorough risk assessments before commencing any fabrication activities. They develop and implement effective risk mitigation strategies, such as using proper equipment, wearing appropriate personal protective gear, and establishing clear safety protocols.

-

Facet 3: Incident Prevention and Emergency Response

Safety-conscious fabricators prioritize incident prevention through rigorous safety protocols and regular inspections. They establish clear emergency response plans and conduct drills to ensure a swift and coordinated response in the event of an incident, minimizing potential harm.

-

Facet 4: Employee Training and Empowerment

Empowering employees with safety knowledge and skills is crucial. Fabricators invest in comprehensive safety training programs, covering topics such as hazard recognition, safe work practices, and emergency procedures. They foster a culture of safety awareness and encourage employees to report any safety concerns.

By choosing a steel fabricator in Louisville with a strong safety record, clients can rest assured that their projects will be executed safely and responsibly. This not only protects workers and the community but also minimizes project delays and costly accidents, contributing to the overall success of the fabrication process.

Insurance

In the realm of steel fabrication in Louisville, insurance plays a pivotal role in safeguarding both clients and fabricators from potential liabilities and financial risks. Properly insured fabricators provide peace of mind and financial protection for all parties involved in the fabrication process.

Consider the following aspects that underscore the importance of insurance in steel fabrication:

-

Protection against Accidents and Damages:

Steel fabrication involves the use of heavy machinery and materials, posing potential risks of accidents and damages. Comprehensive insurance coverage protects fabricators and clients from financial liability in case of injuries, property damage, or equipment malfunctions. -

Legal Compliance:

Many states and municipalities require businesses to carry adequate insurance coverage. Failure to maintain proper insurance can result in legal penalties and fines. Insurance ensures compliance with these regulations. -

Client Confidence:

Working with insured fabricators instills confidence in clients. It demonstrates that the fabricator is financially responsible and committed to protecting all parties involved in the project.

Real-life examples illustrate the practical significance of insurance in steel fabrication in Louisville:

- A local steel fabricator’s insurance policy covered the costs of repairs after a crane accident, preventing financial losses and ensuring the timely completion of the project.

- A steel fabrication company’s liability insurance protected a client from legal claims arising from an alleged design flaw, safeguarding the client’s financial interests.

Understanding the importance of insurance in steel fabrication empowers businesses to make informed decisions. By choosing properly insured fabricators, businesses can mitigate risks, protect their assets, and ensure the smooth execution of their steel fabrication projects.

| Insurance in Steel Fabrication Louisville | |

|---|---|

| Aspect | Importance |

| Protection against Accidents and Damages | Safeguards against financial liability in case of accidents or damages. |

| Legal Compliance | Ensures compliance with state and municipal regulations. |

| Client Confidence | Instills trust and confidence in clients, demonstrating financial responsibility. |

Warranty

In the realm of steel fabrication in Louisville, a warranty serves as a crucial safeguard for clients, offering peace of mind and protection for their investment. A comprehensive warranty ensures that the fabricator stands behind the quality of their work and is committed to rectifying any issues that may arise.

-

Facet 1: Peace of Mind and Assurance

A warranty provides clients with a sense of security, knowing that the fabricator is accountable for the longevity and performance of their work. It eliminates the worry of unexpected expenses or disputes, fostering a trusting relationship between the parties.

-

Facet 2: Protection against Defects and Failures

Warranties cover defects in materials and workmanship, safeguarding clients from financial losses in the event of premature failure or unsatisfactory performance. This protection ensures that the investment in steel fabrication is well-protected.

-

Facet 3: Long-term Value and Durability

A warranty encourages fabricators to use high-quality materials and employ skilled craftsmanship, as they are responsible for the longevity of their work. This translates into durable and reliable steel fabrications that stand the test of time.

-

Facet 4: Enhanced Reputation and Trust

Offering a comprehensive warranty demonstrates a fabricator’s confidence in their abilities and commitment to customer satisfaction. It enhances their reputation and fosters trust among clients, leading to long-term business relationships.

Understanding the importance of a warranty in steel fabrication empowers businesses to make informed decisions. By choosing fabricators who offer robust warranties, clients can protect their investment, ensure the quality of their steel fabrications, and enjoy peace of mind throughout the project.

References

When it comes to steel fabrication in Louisville, references from past clients serve as invaluable sources of information, providing insights into the fabricator’s capabilities, work ethic, and commitment to quality. By requesting and thoroughly reviewing references, businesses can make informed decisions and choose a fabricator who aligns with their project requirements and expectations.

-

Facet 1: Assessing Quality of Workmanship

References offer firsthand accounts of the fabricator’s workmanship and attention to detail. Positive feedback from previous clients indicates a track record of delivering high-quality fabrications that meet or exceed industry standards.

-

Facet 2: Evaluating Project Management Skills

References shed light on the fabricator’s project management abilities, including their communication, responsiveness, and ability to adhere to timelines and budgets. This information helps businesses gauge the fabricator’s efficiency and reliability.

-

Facet 3: Understanding Customer Satisfaction

References provide insights into the overall satisfaction levels of past clients. Positive testimonials indicate a fabricator’s commitment to customer satisfaction, willingness to address concerns, and ability to build lasting relationships.

-

Facet 4: Gaining Industry-Specific Knowledge

References can offer valuable industry-specific knowledge and insights. By speaking to clients in similar industries or with comparable project requirements, businesses can gain a deeper understanding of the fabricator’s expertise and suitability for their specific needs.

In summary, requesting references from past clients is an essential step in selecting a steel fabricator in Louisville. By carefully evaluating these references, businesses can gain valuable information about the fabricator’s workmanship, project management skills, customer satisfaction levels, and industry-specific knowledge. This comprehensive due diligence ensures that businesses make informed decisions and choose a fabricator who will deliver exceptional results and contribute to the success of their steel fabrication project.

Steel Fabrication Louisville FAQs

This FAQ section provides answers to commonly asked questions regarding steel fabrication in Louisville, Kentucky.

Question 1: What factors should be considered when choosing a steel fabricator in Louisville?

Answer: When selecting a steel fabricator in Louisville, it is crucial to consider factors such as experience, capabilities, reputation, certifications, insurance, and warranty. These factors will help ensure that you choose a fabricator who can meet your specific project requirements and deliver high-quality results.

Question 2: How can I ensure the quality of steel fabrication services in Louisville?

Answer: To ensure the quality of steel fabrication services in Louisville, consider the fabricator’s experience, certifications, and reputation. Requesting references from past clients can also provide valuable insights into the fabricator’s quality of work and customer satisfaction levels.

Question 3: What are the typical applications of steel fabrication in Louisville?

Answer: Steel fabrication in Louisville finds applications in various industries, including construction, infrastructure, manufacturing, and transportation. It is used to create structural components for buildings, bridges, stadiums, and industrial equipment, among other applications.

Question 4: What are the advantages of choosing a local steel fabricator in Louisville?

Answer: Choosing a local steel fabricator in Louisville offers several advantages, including reduced transportation costs, faster delivery times, improved communication, and greater flexibility. Local fabricators are also more likely to be familiar with local building codes and regulations.

Question 5: How can I find reputable steel fabricators in Louisville?

Answer: To find reputable steel fabricators in Louisville, you can consult industry directories, search online review platforms, and seek recommendations from architects, engineers, or contractors in the area. It is also advisable to visit the fabricator’s facility and meet with their team to assess their capabilities and professionalism.

Question 6: What are the latest trends in steel fabrication technology in Louisville?

Answer: The steel fabrication industry in Louisville is constantly evolving, with the adoption of advanced technologies such as laser cutting, robotic welding, and automated material handling systems. These technologies enhance precision, efficiency, and productivity, leading to improved quality and reduced lead times.

In summary, steel fabrication plays a vital role in various industries in Louisville, and choosing the right fabricator is essential for ensuring project success. By considering the factors discussed in this FAQ section, you can make informed decisions and select a reputable steel fabricator in Louisville who can deliver high-quality results and meet your specific project requirements.

Transition to the next article section:

For further information on steel fabrication in Louisville, including a comprehensive list of fabricators, industry news, and technical resources, please visit our website.

Tips for Steel Fabrication Louisville

Steel fabrication plays a crucial role in various industries in Louisville, Kentucky. Here are some tips to help you navigate the steel fabrication process and achieve successful project outcomes:

Tip 1: Define Your Project Requirements Clearly

Before approaching steel fabricators, clearly define your project requirements, including the scope of work, specifications, timelines, and budget. This will enable fabricators to provide accurate quotes and tailored solutions that align with your project objectives.

Tip 2: Research and Select a Reputable Fabricator

Thoroughly research and compare different steel fabricators in Louisville. Consider factors such as experience, capabilities, certifications, insurance, and customer reviews. Visit their facilities, meet their team, and assess their quality control processes to ensure they meet your standards.

Tip 3: Establish Clear Communication and Collaboration

Maintain open and effective communication with your chosen fabricator throughout the project. Provide clear instructions, respond promptly to inquiries, and actively participate in design reviews to avoid misunderstandings and ensure the project progresses smoothly.

Tip 4: Review and Approve Detailed Drawings

Carefully review and approve detailed drawings and specifications provided by the fabricator. Ensure that they accurately reflect your project requirements and meet industry standards. This step helps prevent errors and costly rework during fabrication and installation.

Tip 5: Plan for Inspection and Quality Control

Establish a clear inspection and quality control plan. Determine the inspection points, acceptance criteria, and responsibilities of both parties. Regular inspections throughout the fabrication process help identify and address any deviations from specifications, ensuring the final product meets the desired quality standards.

Tip 6: Consider Value Engineering and Cost Optimization

Explore value engineering options with your fabricator to optimize costs while maintaining the integrity of the project. Discuss alternative materials, design modifications, or fabrication techniques that can reduce expenses without compromising quality or functionality.

Tip 7: Ensure Timely Delivery and Installation

Coordinate with the fabricator to establish a realistic delivery schedule and plan for efficient installation. Proper planning helps avoid delays, minimizes disruption to your project timeline, and ensures the fabricated components are delivered and installed on time.

Tip 8: Seek Professional Advice When Needed

If you encounter technical challenges or have specific requirements, do not hesitate to seek professional advice from engineers, architects, or industry experts. Their knowledge and experience can provide valuable guidance and help you make informed decisions throughout the steel fabrication process.

By following these tips, you can effectively manage your steel fabrication project in Louisville, ensuring timely completion, high quality, and cost-effectiveness. Remember to approach the process with a collaborative mindset, maintain open communication, and prioritize quality control to achieve successful project outcomes.

Conclusion

Steel fabrication plays a vital role in the construction and industrial sectors of Louisville, Kentucky. This comprehensive guide has explored the key aspects of steel fabrication in Louisville, providing valuable insights for businesses and individuals seeking high-quality steel fabrication services.

Choosing the right steel fabricator is paramount to ensuring project success. By considering factors such as experience, capabilities, certifications, insurance, and customer satisfaction, clients can make informed decisions and select a fabricator who can deliver exceptional results. Effective communication, clear project requirements, and rigorous quality control measures are crucial throughout the fabrication process.

The future of steel fabrication in Louisville looks promising, with ongoing advancements in technology and a growing emphasis on sustainability. By embracing innovation and partnering with reputable fabricators, businesses can harness the potential of steel fabrication to create durable, cost-effective, and aesthetically pleasing structures that contribute to the city’s built environment.

In conclusion, steel fabrication in Louisville is a thriving industry that offers a wide range of services and applications. By following the tips and recommendations outlined in this guide, clients can navigate the steel fabrication process effectively and achieve successful project outcomes.