Steel fabrication is a critical process that plays a vital role in various industries, including construction, manufacturing, and infrastructure development. In Phoenix, Arizona, steel fabrication companies leverage advanced technologies and skilled craftsmanship to deliver high-quality steel products for diverse applications.

Editor’s Note: Steel fabrication in Phoenix is a topic of significant importance due to the city’s thriving construction industry and its strategic location as a transportation hub. This guide provides valuable insights into the capabilities and services offered by steel fabricators in Phoenix, empowering readers to make informed decisions for their steel fabrication needs.

Our team has conducted extensive research and gathered information from industry experts to compile this comprehensive guide on steel fabrication in Phoenix. By exploring the key aspects of this industry, we aim to help businesses and individuals navigate the complexities of steel fabrication and make optimal choices for their projects.

Key Differences

| Characteristic | Phoenix Steel Fabrication | Other Regions |

|---|---|---|

| Market Demand | High demand due to Phoenix’s growing construction industry | Varies depending on regional economic conditions |

| Labor Availability | Skilled workforce with specialized training in steel fabrication | May face labor shortages in certain areas |

| Technology Adoption | Advanced equipment and software for efficient production | Technology adoption may vary across different regions |

| Industry Standards | Adherence to strict industry standards and certifications | Standards may differ in other regions, potentially affecting quality |

Main Article Topics:

- Types of Steel Fabrication Services in Phoenix

- Benefits of Choosing Phoenix Steel Fabricators

- Factors to Consider When Selecting a Steel Fabricator

- Case Studies and Success Stories in Phoenix Steel Fabrication

- Future Trends and Innovations in Steel Fabrication

Steel Fabrication Phoenix

Steel fabrication plays a vital role in Phoenix’s thriving construction industry, offering a wide range of services and benefits. Here are 11 key aspects to consider when exploring steel fabrication in Phoenix:

- Expertise: Skilled workforce with specialized training in steel fabrication

- Technology: Advanced equipment and software for efficient production

- Quality: Adherence to strict industry standards and certifications

- Capacity: Ability to handle large-scale projects with complex requirements

- Flexibility: Customization and adaptability to meet specific project needs

- Innovation: Continuous adoption of new technologies and techniques

- Collaboration: Strong partnerships with architects, engineers, and contractors

- Safety: Commitment to maintaining a safe work environment

- Sustainability: Use of environmentally friendly practices and materials

- Cost-effectiveness: Competitive pricing and value for money

- Reputation: Established companies with a proven track record

These key aspects are interconnected and contribute to the overall success of steel fabrication in Phoenix. For instance, the skilled workforce and advanced technology enable fabricators to produce high-quality steel products that meet the demanding requirements of the construction industry. The commitment to safety ensures a productive and hazard-free work environment, while the focus on sustainability aligns with the growing demand for eco-friendly practices. By considering these key aspects, businesses and individuals can make informed decisions when selecting a steel fabricator in Phoenix, ensuring the successful execution of their projects.

Expertise

In the realm of steel fabrication in Phoenix, expertise is paramount. The city boasts a skilled workforce that possesses specialized training, enabling them to execute complex projects with precision and efficiency. This expertise is a cornerstone of Phoenix’s steel fabrication industry, contributing to its reputation for quality and reliability.

-

Facet 1: Advanced Technical Skills

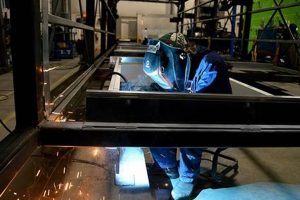

Phoenix’s steel fabricators employ individuals with advanced technical skills, including welding, cutting, and forming. These skilled workers undergo rigorous training programs to master the latest techniques and operate sophisticated equipment, ensuring that steel products meet the highest industry standards.

-

Facet 2: Industry Certifications

Many steel fabricators in Phoenix hold industry certifications, such as the American Welding Society (AWS) and the American Institute of Steel Construction (AISC). These certifications demonstrate a commitment to quality and adherence to industry best practices, giving clients confidence in the reliability and safety of their steel products.

-

Facet 3: Project Management Expertise

Steel fabrication projects often involve complex coordination and management. Phoenix’s steel fabricators have experienced project managers who oversee every aspect of a project, from design and engineering to fabrication and installation. Their expertise ensures that projects are completed on time, within budget, and to the highest quality standards.

-

Facet 4: Collaboration and Innovation

Steel fabricators in Phoenix foster a culture of collaboration and innovation. They work closely with architects, engineers, and contractors to develop creative and cost-effective solutions for complex steel structures. This collaborative approach drives innovation and ensures that Phoenix remains at the forefront of steel fabrication techniques.

The expertise of Phoenix’s steel fabrication workforce is a key differentiator in the industry. It enables fabricators to handle large-scale projects, meet demanding specifications, and deliver high-quality steel products that meet the unique needs of the city’s construction sector. By leveraging the expertise of skilled professionals, steel fabrication in Phoenix continues to thrive and contribute to the city’s architectural landscape.

Technology

In steel fabrication, technology plays a pivotal role in enhancing efficiency and productivity. Phoenix-based steel fabricators have embraced advanced equipment and software, enabling them to streamline production processes and meet the increasing demands of the construction industry.

Computer-Aided Design (CAD) and Engineering (CAE):CAD and CAE software allow engineers to create precise 3D models and simulations of steel structures. This technology streamlines the design process, reduces errors, and enables fabricators to optimize material usage. Sophisticated analysis tools within CAE software help engineers assess structural integrity, identify potential issues, and make informed decisions during the design phase.

Automated Production Equipment:Steel fabricators in Phoenix utilize automated machinery, such as CNC (computer numerical control) machines, to perform repetitive tasks with precision and speed. CNC machines can cut, drill, and form steel components with minimal manual intervention, increasing production efficiency and reducing the risk of errors. Automated welding systems ensure consistent and high-quality welds, enhancing the structural integrity of steel fabrications.

Advanced Project Management Software:Steel fabrication projects often involve complex coordination and management. Advanced project management software helps fabricators track project progress, manage resources, and optimize workflow. These software solutions enable real-time collaboration among project stakeholders, ensuring timely delivery and efficient utilization of resources.

Data Analytics and Quality Control:Data analytics is increasingly used in steel fabrication to monitor production processes, identify areas for improvement, and ensure consistent quality. Sensors and monitoring systems collect data on equipment performance, material usage, and production output. This data is analyzed to identify trends, optimize processes, and make data-driven decisions for continuous improvement.

The integration of advanced technology in steel fabrication phoenix has transformed the industry, enabling fabricators to produce high-quality steel products with greater efficiency and precision. By leveraging the latest equipment and software, Phoenix-based steel fabricators are well-positioned to meet the evolving demands of the construction sector and contribute to the city’s architectural landscape.

Quality

In the realm of steel fabrication, adhering to strict industry standards and certifications is paramount to ensuring the quality and reliability of steel products. Phoenix-based steel fabricators are committed to meeting these standards, which are established by recognized organizations to ensure that steel products meet specific performance criteria and safety requirements.

-

Facet 1: Meeting Building Codes and Regulations

Steel fabricators in Phoenix must comply with local building codes and regulations, which set forth requirements for structural safety, fire resistance, and other performance aspects. Adherence to these codes ensures that steel structures meet the minimum safety standards and are suitable for their intended use, contributing to the overall safety and integrity of buildings in Phoenix.

-

Facet 2: Industry Certifications and Standards

Phoenix steel fabricators often hold industry certifications, such as those from the American Welding Society (AWS) and the American Institute of Steel Construction (AISC). These certifications demonstrate a commitment to quality and adherence to industry best practices. Certified fabricators have undergone rigorous audits and testing to ensure that their processes, equipment, and personnel meet the highest standards.

-

Facet 3: Quality Control Measures

Steel fabricators in Phoenix implement comprehensive quality control measures throughout their production processes. These measures include regular inspections, testing of materials and welds, and documentation of all quality-related activities. By maintaining strict quality control, fabricators can identify and address any potential issues early on, ensuring that only high-quality steel products are delivered to clients.

-

Facet 4: Continuous Improvement and Innovation

Phoenix steel fabricators are committed to continuous improvement and innovation in their quality management systems. They invest in training, research, and development to stay abreast of the latest industry trends and best practices. By embracing innovation, fabricators can enhance their processes, improve product quality, and meet the evolving demands of the construction sector.

The adherence to industry standards and certifications by steel fabricators in Phoenix serves as a testament to their commitment to quality and reliability. By meeting or exceeding these standards, fabricators ensure that the steel structures they produce are safe, durable, and meet the specific requirements of their clients. Ultimately, this commitment to quality contributes to the reputation of Phoenix as a hub for high-quality steel fabrication.

Capacity

The capacity to handle large-scale projects with complex requirements is a defining characteristic of steel fabrication in Phoenix, enabling the city’s fabricators to undertake ambitious and intricate construction endeavors. This capacity stems from a combination of factors, including:

- Skilled Workforce: Phoenix steel fabricators employ a highly skilled workforce with extensive experience in handling large-scale projects. Their expertise ensures that complex structural designs are executed with precision and efficiency.

- Advanced Equipment: Phoenix fabricators utilize state-of-the-art equipment, including CNC machines, automated welding systems, and advanced software, to streamline production and ensure accuracy in complex fabrication processes.

- Project Management Expertise: Steel fabricators in Phoenix possess exceptional project management capabilities, enabling them to coordinate and manage large-scale projects effectively. They work closely with architects, engineers, and contractors to ensure seamless execution and timely delivery.

The ability to handle large-scale projects is crucial for Phoenix steel fabrication companies, as the city is home to numerous high-profile construction projects, including skyscrapers, stadiums, and infrastructure developments. By leveraging their capacity and expertise, Phoenix fabricators contribute to the city’s architectural landscape and economic growth.

Case Study: Arizona Cardinals Stadium

The Arizona Cardinals Stadium, completed in 2006, is a testament to the capacity of Phoenix steel fabricators. The stadium’s retractable roof, a marvel of engineering, required the fabrication and installation of massive steel trusses and complex structural components. Phoenix-based steel fabricators played a pivotal role in this project, demonstrating their ability to handle large-scale projects with intricate requirements.

Conclusion

In conclusion, the capacity to handle large-scale projects with complex requirements is an essential aspect of steel fabrication in Phoenix. It enables the city’s fabricators to undertake ambitious construction projects, contributing to the city’s architectural landscape and economic development. The skilled workforce, advanced equipment, and project management expertise of Phoenix steel fabricators ensure that complex structural designs are executed with precision, efficiency, and adherence to the highest industry standards.

Flexibility

In the realm of steel fabrication, flexibility and adaptability are essential qualities that enable fabricators to meet the unique demands of diverse construction projects. Phoenix-based steel fabricators excel in this aspect, offering customized solutions and adapting their services to meet specific project requirements.

-

Facet 1: Design Customization

Steel fabricators in Phoenix collaborate closely with architects and engineers to bring unique design visions to life. They possess the expertise to modify and adapt standard steel components or create entirely custom fabrications to meet specific architectural or structural needs. This customization capability allows for the creation of distinctive and visually striking structures that cater to the specific aesthetic and functional requirements of each project.

-

Facet 2: Adaptability to Site Conditions

Construction sites can present unforeseen challenges and varying conditions. Phoenix steel fabricators demonstrate adaptability by modifying their fabrication processes and techniques to accommodate site constraints or changes in project requirements. They can adjust the dimensions, configurations, and finishes of steel components to ensure a seamless fit and efficient installation, minimizing disruptions and delays during the construction phase.

-

Facet 3: Accommodation of Late Design Changes

Design modifications and changes are common during complex construction projects. Steel fabricators in Phoenix are flexible enough to accommodate late design changes without compromising the integrity or timeline of the project. They can quickly adjust their fabrication schedules and processes to incorporate design revisions, ensuring that the final product meets the updated specifications and maintains the desired aesthetic and structural performance.

-

Facet 4: Integration with Other Building Systems

Steel structures often need to integrate seamlessly with other building systems, such as HVAC, plumbing, and electrical. Phoenix steel fabricators possess the foresight and technical expertise to plan and coordinate the integration of steel components with these systems during the fabrication process. This integrated approach ensures that the final structure is not only structurally sound but also functional and efficient, meeting the overall performance requirements of the building.

The flexibility and adaptability of steel fabricators in Phoenix empower them to deliver customized solutions that meet the unique demands of each construction project. Their ability to adapt to changing requirements, accommodate late design changes, and seamlessly integrate steel structures with other building systems makes them invaluable partners in the construction industry. By embracing flexibility, Phoenix steel fabricators contribute to the successful execution of complex and innovative architectural projects that shape the city’s skyline and enhance its built environment.

Innovation

Innovation plays a pivotal role in the steel fabrication industry, driving advancements that enhance efficiency, precision, and the overall quality of steel products. Phoenix-based steel fabricators are at the forefront of innovation, continuously adopting new technologies and techniques to meet the evolving demands of the construction sector.

-

Facet 1: Advanced Design and Engineering Software

Steel fabricators in Phoenix leverage cutting-edge design and engineering software to create precise 3D models and simulations of steel structures. These software tools enable engineers to optimize designs, reduce material waste, and identify potential issues early in the design phase, leading to more efficient and cost-effective fabrication processes.

-

Facet 2: Automated Production Technologies

Automation has transformed steel fabrication, with Phoenix fabricators employing CNC (computer numerical control) machines, robotic welding systems, and other automated technologies. These technologies increase production efficiency, reduce errors, and ensure consistent quality in the fabrication of complex steel components.

-

Facet 3: Data Analytics and Process Optimization

Steel fabricators in Phoenix utilize data analytics to monitor and optimize their production processes. Sensors and monitoring systems collect data on equipment performance, material usage, and production output. This data is analyzed to identify areas for improvement, reduce waste, and enhance overall efficiency.

-

Facet 4: Sustainable Fabrication Techniques

Sustainability is a key focus area for Phoenix steel fabricators. They adopt innovative techniques to reduce environmental impact, such as using recycled steel materials, implementing energy-efficient processes, and exploring renewable energy sources. By embracing sustainability, fabricators contribute to the creation of environmentally friendly and responsible steel structures.

The continuous adoption of new technologies and techniques by steel fabricators in Phoenix has revolutionized the industry, enabling them to produce high-quality steel products with greater efficiency, precision, and sustainability. These innovations contribute to the city’s reputation as a hub for advanced steel fabrication, supporting the construction of iconic structures and shaping the architectural landscape of Phoenix.

Collaboration

In the realm of steel fabrication, collaboration is paramount. Phoenix-based steel fabricators foster strong partnerships with architects, engineers, and contractors, forming a cohesive team that brings construction projects to life. This collaboration is essential for ensuring the successful execution of complex steel structures that meet the highest standards of quality and safety.

The collaborative process begins with the design phase, where architects and engineers work closely with steel fabricators to translate design concepts into detailed fabrication plans. Steel fabricators provide valuable input on material selection, structural integrity, and constructability, ensuring that the design aligns with the practical realities of steel fabrication. This early collaboration minimizes potential issues during the fabrication and construction stages, saving time and resources.

During the fabrication process, steel fabricators maintain constant communication with contractors to coordinate delivery schedules and ensure that the fabricated steel components arrive on-site at the right time. This coordination is crucial for minimizing disruptions during construction and keeping the project on track. Furthermore, steel fabricators often provide on-site technical support to assist with the erection and installation of steel structures, ensuring proper alignment and adherence to design specifications.

The benefits of collaboration extend beyond the immediate project. Strong relationships between steel fabricators, architects, engineers, and contractors foster a culture of knowledge sharing and innovation. By working together on multiple projects, these professionals develop a deep understanding of each other’s strengths and areas of expertise. This shared knowledge enables them to approach future projects with a collaborative mindset, leveraging lessons learned and best practices to achieve even greater success.

In Phoenix, collaboration is not just a buzzword but a deeply ingrained practice in the steel fabrication industry. It is a key factor in the city’s reputation for delivering high-quality steel structures that grace its skyline and contribute to its architectural heritage.

Key Insights:

- Collaboration between steel fabricators, architects, engineers, and contractors is essential for the successful execution of complex steel structures.

- Early collaboration during the design phase minimizes potential issues during fabrication and construction.

- Ongoing communication and coordination between steel fabricators and contractors ensure timely delivery and proper installation of steel components.

- Strong partnerships foster a culture of knowledge sharing and innovation, leading to continuous improvement in the steel fabrication industry.

Safety

In steel fabrication, maintaining a safe work environment is paramount, as the industry involves the handling of heavy equipment, hazardous materials, and complex processes. Phoenix-based steel fabricators prioritize safety by implementing comprehensive measures to protect their employees and create a culture of risk awareness.

-

Facet 1: Industry Regulations and Standards

Steel fabricators in Phoenix adhere to strict industry regulations and safety standards, such as those set forth by the Occupational Safety and Health Administration (OSHA). These regulations provide a framework for safe work practices, including guidelines for machine guarding, personal protective equipment (PPE), and emergency procedures. By complying with these standards, fabricators demonstrate their commitment to maintaining a safe workplace.

-

Facet 2: Risk Assessment and Mitigation

Steel fabricators conduct thorough risk assessments to identify potential hazards in their workplaces. These assessments involve evaluating equipment, processes, and work areas to determine the likelihood and severity of accidents or injuries. Once risks are identified, fabricators implement mitigation measures, such as engineering controls, administrative controls, and training programs, to minimize the chances of incidents occurring.

-

Facet 3: Employee Training and Education

A well-trained workforce is essential for workplace safety. Steel fabricators in Phoenix provide comprehensive training programs to educate employees on safe work practices, emergency procedures, and the proper use of equipment. Regular training reinforces safe behaviors and ensures that employees are aware of the potential hazards associated with their jobs.

-

Facet 4: Continuous Improvement and Innovation

Steel fabricators in Phoenix continuously seek ways to improve their safety performance. They invest in new technologies, such as automated equipment and sensor-based monitoring systems, to reduce the risk of accidents and injuries. By embracing innovation, fabricators can enhance their safety measures and create a more secure work environment for their employees.

The commitment to safety is deeply ingrained in the culture of steel fabrication in Phoenix. By adhering to industry standards, conducting risk assessments, providing employee training, and embracing innovation, Phoenix-based steel fabricators prioritize the well-being of their workforce and contribute to a positive safety record in the industry.

Sustainability

In the realm of steel fabrication, sustainability has become an increasingly important consideration. Phoenix-based steel fabricators are embracing environmentally friendly practices and materials to reduce their ecological footprint and contribute to a more sustainable built environment.

-

Facet 1: Recycled Steel Utilization

Many steel fabricators in Phoenix prioritize the use of recycled steel in their production processes. Recycled steel offers a more sustainable alternative to virgin steel, as it reduces the need for mining and the associated environmental impacts. By incorporating recycled steel into their products, fabricators help conserve natural resources and minimize waste.

-

Facet 2: Energy-Efficient Production

Steel fabrication can be an energy-intensive process. Phoenix-based fabricators are implementing energy-efficient technologies and practices to reduce their energy consumption. These measures include optimizing equipment performance, utilizing renewable energy sources, and implementing energy-saving lighting systems. By reducing their energy footprint, fabricators contribute to a cleaner and more sustainable future.

-

Facet 3: Waste Reduction and Recycling

Steel fabrication generates various types of waste, including scrap metal and packaging materials. Phoenix steel fabricators are committed to minimizing waste and promoting recycling. They implement waste management programs that involve sorting, recycling, and reusing materials whenever possible. By reducing waste and promoting recycling, fabricators help conserve resources and divert materials from landfills.

-

Facet 4: Environmental Certifications and Standards

To demonstrate their commitment to sustainability, Phoenix steel fabricators are pursuing environmental certifications and adhering to industry standards. These certifications and standards provide a framework for sustainable practices and help fabricators meet growing customer demand for environmentally responsible products.

The adoption of sustainable practices and materials by steel fabricators in Phoenix is a reflection of their commitment to environmental stewardship and the creation of a more sustainable built environment. By embracing sustainability, Phoenix fabricators are not only reducing their ecological impact but also positioning themselves as responsible partners in the construction industry.

Cost-effectiveness

In the realm of steel fabrication, cost-effectiveness is a crucial factor for businesses and individuals seeking high-quality steel products without breaking the bank. Phoenix-based steel fabricators offer competitive pricing and value for money, making them a compelling choice for diverse construction projects.

-

Facet 1: Economies of Scale

Phoenix steel fabricators benefit from economies of scale due to the city’s thriving construction industry. The high demand for steel products allows fabricators to optimize their production processes, reducing costs and passing on the savings to customers. This cost advantage enables Phoenix fabricators to offer competitive pricing while maintaining high quality standards.

-

Facet 2: Local Sourcing and Reduced Transportation Costs

Phoenix is a major transportation hub, providing steel fabricators with access to a wide range of raw materials and supplies. The proximity to suppliers reduces transportation costs, allowing fabricators to offer more competitive pricing compared to companies located in regions with higher transportation expenses.

-

Facet 3: Technological Advancements and Efficiency

Phoenix steel fabricators embrace technological advancements to enhance efficiency and reduce production costs. Automated equipment, advanced software, and lean manufacturing techniques enable fabricators to streamline processes, minimize waste, and lower operating expenses. These cost savings are often passed on to customers, resulting in more affordable steel products.

-

Facet 4: Experienced Workforce and Productivity

The skilled workforce in Phoenix possesses extensive experience in steel fabrication, contributing to high levels of productivity and efficiency. Experienced workers can complete projects faster, reduce errors, and minimize rework, resulting in lower overall costs for customers. Additionally, the availability of a skilled labor pool allows Phoenix fabricators to offer competitive wages, further contributing to cost-effectiveness.

The combination of competitive pricing and value for money offered by Phoenix steel fabricators makes them a compelling choice for businesses and individuals seeking high-quality, cost-effective steel products. By leveraging economies of scale, optimizing production processes, and capitalizing on local resources, Phoenix fabricators deliver exceptional value without compromising on quality or service.

Reputation

In the realm of steel fabrication, the reputation of a company holds immense significance, as it reflects their ability to deliver high-quality products, meet deadlines, and maintain a strong customer focus. Phoenix, Arizona has emerged as a hub for reputable steel fabrication companies with a proven track record, contributing to the city’s thriving construction industry and skyline.

-

Facet 1: Years of Experience and Expertise

Established steel fabrication companies in Phoenix have accumulated years of experience, honing their skills and expertise in the field. This experience enables them to handle complex projects with confidence, leveraging their knowledge to find innovative solutions and deliver exceptional results.

-

Facet 2: Portfolio of Successful Projects

A proven track record is often showcased through a portfolio of successful projects. Phoenix steel fabrication companies can demonstrate their capabilities by presenting examples of their work, highlighting the diversity of projects they have undertaken and the satisfied clients they have served.

-

Facet 3: Certifications and Industry Recognition

Certifications and industry recognition serve as independent validation of a company’s reputation. Phoenix steel fabricators may hold certifications from organizations such as the American Welding Society (AWS) or the American Institute of Steel Construction (AISC), demonstrating their adherence to industry and best practices.

-

Facet 4: Positive Customer Testimonials and Reviews

Positive customer testimonials and reviews are powerful indicators of a company’s reputation. Satisfied clients are more likely to provide positive feedback, which can be shared on the company’s website, social media platforms, or industry directories. These testimonials offer valuable insights into the company’s customer service, product quality, and overall performance.

The reputation of established steel fabrication companies in Phoenix is built on a foundation of experience, expertise, successful projects, industry recognition, and positive customer feedback. By choosing a reputable company with a proven track record, clients can increase their chances of a successful project outcome, ensuring that their steel fabrication needs are met with the highest standards of quality and service.

FAQs about Steel Fabrication in Phoenix

This section addresses frequently asked questions (FAQs) about steel fabrication in Phoenix, providing informative answers to common concerns or misconceptions.

Question 1: What are the advantages of choosing steel fabrication companies in Phoenix?

Answer: Phoenix steel fabricators offer several advantages, including expertise, advanced technology, commitment to quality, capacity for large-scale projects, flexibility, innovation, collaboration, safety, sustainability, cost-effectiveness, and a proven track record.

Question 2: How do Phoenix steel fabricators ensure the quality of their products?

Answer: Quality assurance in Phoenix steel fabrication involves adherence to industry standards and certifications, implementation of comprehensive quality control measures, and a commitment to continuous improvement and innovation.

Question 3: Can Phoenix steel fabricators handle large-scale projects with complex requirements?

Answer: Yes, Phoenix steel fabricators possess the capacity to undertake large-scale projects with intricate requirements, leveraging their skilled workforce, advanced equipment, and project management expertise.

Question 4: Are Phoenix steel fabricators flexible and adaptable to meet specific project needs?

Answer: Flexibility is a key characteristic of Phoenix steel fabricators, enabling them to customize designs, adapt to site conditions, accommodate late design changes, and integrate steel structures with other building systems.

Question 5: How do Phoenix steel fabricators prioritize safety in their operations?

Answer: Safety is paramount for Phoenix steel fabricators, who adhere to industry regulations and standards, conduct thorough risk assessments, provide employee training, and embrace continuous improvement and innovation to maintain a safe work environment.

Question 6: Are Phoenix steel fabricators committed to sustainability?

Answer: Yes, Phoenix steel fabricators prioritize sustainability by using recycled steel, implementing energy-efficient production processes, minimizing waste, and pursuing environmental certifications and standards to reduce their ecological footprint.

These FAQs provide a comprehensive overview of key aspects related to steel fabrication in Phoenix, addressing common concerns and highlighting the strengths of the industry in the city.

Next Article Section: Conclusion

Steel Fabrication Phoenix

Steel fabrication plays a crucial role in Phoenix’s construction industry, contributing to the city’s architectural landscape and infrastructure development. By following these expert tips, businesses and individuals can navigate the complexities of steel fabrication and make informed decisions for their projects.

Tip 1: Define Project Requirements Clearly

Clearly defining project requirements at the outset is essential for successful steel fabrication. This includes specifying the desired design, functionality, timelines, and budget. Open communication and collaboration with the steel fabricator ensure that the final product aligns with the intended purpose and meets expectations.

Tip 2: Choose a Reputable Fabricator

Selecting a reputable steel fabricator with a proven track record is paramount. Consider factors such as experience, expertise, certifications, and customer testimonials. A reputable fabricator will provide high-quality products, adhere to industry standards, and prioritize safety and sustainability.

Tip 3: Leverage Technology and Innovation

Embrace technological advancements and innovative techniques in steel fabrication. Advanced software, automated equipment, and data analytics can enhance efficiency, precision, and overall project outcomes. Partner with fabricators who invest in continuous improvement and stay abreast of the latest industry trends.

Tip 4: Foster Collaboration and Communication

Strong collaboration among architects, engineers, contractors, and steel fabricators is essential for project success. Open communication channels, regular meetings, and shared project plans facilitate seamless coordination and timely decision-making. By fostering a collaborative environment, potential issues can be identified and resolved promptly.

Tip 5: Prioritize Safety and Quality

Safety and quality should be non-negotiable principles in steel fabrication. Ensure that the fabricator adheres to industry safety regulations, implements comprehensive quality control measures, and maintains a clean and organized work environment. Prioritizing safety and quality not only protects workers and the public but also ensures the longevity and integrity of the fabricated steel structures.

By incorporating these tips into their approach, businesses and individuals can maximize the benefits of steel fabrication in Phoenix, achieving successful project outcomes and contributing to the city’s architectural legacy.

Conclusion

In conclusion, steel fabrication in Phoenix has emerged as a cornerstone of the city’s thriving construction industry. By leveraging expertise, technology, quality, capacity, flexibility, innovation, collaboration, safety, sustainability, and cost-effectiveness, Phoenix steel fabricators have played a vital role in shaping the city’s architectural landscape.

The future of steel fabrication in Phoenix looks promising, with continued advancements in technology, sustainability, and collaborative practices. As the city grows and evolves, steel fabrication will undoubtedly remain a critical component, supporting the construction of iconic structures and contributing to the city’s economic prosperity. By embracing innovation and maintaining the highest standards of quality and safety, Phoenix steel fabricators will continue to drive the industry forward and contribute to the city’s architectural legacy.