Steel fabrication shops play a vital role in various industries, transforming raw steel into intricate components and structures. These shops possess specialized equipment and skilled professionals to cut, shape, and weld steel to precise specifications, catering to diverse sectors such as construction, manufacturing, and transportation.

Editor’s Note: Understanding steel fabrication shops is crucial for businesses and individuals seeking high-quality steel components and structures. This guide provides comprehensive information to help readers make informed decisions about their steel fabrication needs.

After analyzing market trends and gathering insights from industry experts, we have compiled this comprehensive guide to help our target audience make the right decision when choosing steel fabrication shops.

Key Differences:

| Factor | Key Differences |

|---|---|

| Equipment | Advanced CNC machines, laser cutters, and welding technologies |

| Expertise | Skilled engineers and fabricators with industry certifications |

| Materials | Access to a wide range of steel grades and alloys |

| Quality Control | Rigorous quality assurance processes to ensure precision and durability |

Main Article Topics:

- Types of Steel Fabrication Shops

- Benefits of Using Steel Fabrication Shops

- Choosing the Right Steel Fabrication Shop

- Quality Standards and Certifications

- Recent Innovations in Steel Fabrication

Steel Fabrication Shops

Steel fabrication shops play a crucial role in various industries, from construction to manufacturing. They possess specialized equipment and skilled professionals to cut, shape, and weld steel to precise specifications. To understand the comprehensive capabilities of steel fabrication shops, it is essential to explore key aspects related to their operations:

- Equipment: Advanced CNC machines, laser cutters, and welding technologies

- Expertise: Skilled engineers and fabricators with industry certifications

- Materials: Access to a wide range of steel grades and alloys

- Quality Control: Rigorous quality assurance processes to ensure precision and durability

- Customization: Ability to create custom steel components and structures based on specific requirements

- Project Management: Experienced project managers to oversee projects from design to delivery

- Safety: Adherence to strict safety regulations and industry best practices

- Communication: Effective communication channels to ensure clear understanding of project specifications

- Sustainability: Commitment to environmentally friendly practices and use of sustainable materials

- Innovation: Continuous investment in new technologies and techniques to enhance efficiency and quality

- Industry Standards: Compliance with industry standards such as ISO 9001 and AWS D1.1

These key aspects collectively contribute to the success and reliability of steel fabrication shops. They ensure that clients receive high-quality steel components and structures that meet their exact requirements, while adhering to industry standards and safety regulations. Understanding these aspects empowers businesses and individuals to make informed decisions when choosing a steel fabrication shop for their projects.

Equipment

In the realm of steel fabrication, advanced equipment plays a pivotal role in shaping and transforming raw steel into intricate components and structures. Steel fabrication shops rely on a suite of sophisticated technologies to achieve precision, efficiency, and quality in their operations.

CNC machines, laser cutters, and welding technologies are indispensable tools in the steel fabrication process. CNC (Computer Numerical Control) machines are automated systems that utilize computer-aided design (CAD) software to control the movement of cutting and shaping tools. This enables precise cutting, drilling, and milling of steel components, ensuring dimensional accuracy and repeatability.

Laser cutters employ high-powered lasers to cut through steel with unparalleled precision and speed. This technology is particularly advantageous for intricate designs and complex shapes, offering clean and burr-free cuts. Laser cutters also minimize heat distortion, preserving the integrity of the steel material.

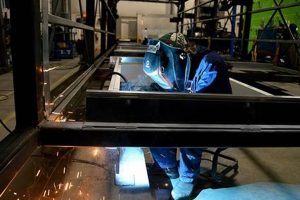

Welding technologies play a crucial role in joining steel components together. Steel fabrication shops employ advanced welding techniques such as MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and arc welding to create strong and durable welds. Skilled welders ensure that welds meet stringent quality standards, ensuring structural integrity and longevity.

The combination of advanced CNC machines, laser cutters, and welding technologies empowers steel fabrication shops to produce high-quality steel components and structures that meet the demanding requirements of various industries. These technologies enhance productivity, reduce lead times, and minimize material waste, ultimately contributing to cost-effective and efficient steel fabrication solutions.

Key Insights:

- Advanced equipment is essential for precision, efficiency, and quality in steel fabrication.

- CNC machines enable precise cutting and shaping of steel components.

- Laser cutters offer high-speed and high-precision cutting for intricate designs.

- Advanced welding technologies create strong and durable welds, ensuring structural integrity.

- The combination of these technologies enhances productivity, reduces lead times, and minimizes material waste.

Expertise

In steel fabrication shops, expertise is paramount. Skilled engineers and fabricators with industry certifications possess the knowledge, experience, and training to transform raw steel into high-quality components and structures. Their expertise encompasses various facets that contribute to the success of steel fabrication projects.

- Design and Engineering: Certified engineers collaborate closely with clients to understand their design intent and translate it into detailed fabrication plans. Their expertise ensures that the final product meets functional and structural requirements.

- Material Selection: Skilled engineers have a deep understanding of different steel grades and alloys. They advise clients on the optimal material selection based on factors such as strength, durability, and cost, ensuring that the fabricated components meet the specific demands of the project.

- Fabrication Techniques: Certified fabricators possess proficiency in various fabrication techniques, including cutting, bending, welding, and assembly. They utilize advanced equipment and follow industry best practices to achieve precise dimensions, high-quality welds, and overall structural integrity.

- Quality Control: Fabricators with industry certifications adhere to rigorous quality control standards throughout the fabrication process. They conduct thorough inspections and tests to ensure that the fabricated components meet the required specifications and industry codes.

The expertise of skilled engineers and fabricators in steel fabrication shops is crucial for delivering high-quality products that meet the exact requirements of clients. Their knowledge, experience, and certifications guarantee precision, durability, and compliance with industry standards, ensuring the success and longevity of steel structures in various applications.

Materials

In the realm of steel fabrication shops, access to a wide range of steel grades and alloys is of paramount importance. The choice of steel material directly influences the properties and performance of the fabricated components and structures, making it an essential consideration throughout the fabrication process.

- Structural Steels: These steels are widely used in construction and infrastructure projects due to their high strength-to-weight ratio and durability. Common structural steel grades include A36, A572, and A913.

- Alloy Steels: Alloy steels are created by adding specific elements, such as chromium, nickel, or molybdenum, to enhance their properties. They offer increased strength, hardness, and toughness, making them suitable for demanding applications in industries like automotive and manufacturing.

- Stainless Steels: Stainless steels are known for their corrosion resistance and aesthetic appeal. They are commonly used in applications where hygiene and durability are crucial, such as food processing equipment and architectural facades.

- Tool Steels: Tool steels are designed specifically for cutting and forming tools. They possess exceptional hardness and wear resistance, enabling them to withstand the rigors of machining and metalworking operations.

Steel fabrication shops that have access to a diverse range of steel grades and alloys can cater to a wider variety of client requirements. They can select the most appropriate material based on factors such as strength, durability, corrosion resistance, and cost. This ensures that the fabricated components meet the specific demands of the intended application, maximizing performance and longevity.

Quality Control

Quality control is the cornerstone of steel fabrication shops, ensuring that the fabricated components and structures meet the highest standards of precision and durability. Rigorous quality assurance processes are implemented at every stage of the fabrication process, from material selection to final assembly.

- Material Inspection: Incoming steel materials are thoroughly inspected to verify their compliance with the specified grades and dimensions. This includes visual inspection, chemical analysis, and mechanical testing to ensure that the material meets the required properties.

- Fabrication Process Control: During fabrication, each step is carefully monitored and controlled to ensure precision and accuracy. This includes regular dimensional checks, welding inspections, and non-destructive testing to identify and rectify any potential defects.

- Welding Quality: Welding is a critical aspect of steel fabrication, and rigorous quality control measures are employed to ensure the integrity of welded joints. Welders are certified and undergo regular training to maintain their skills and adhere to industry standards.

- Final Inspection and Testing: Before delivery, fabricated components and structures undergo a comprehensive final inspection. This includes dimensional verification, surface finish evaluation, and functional testing to ensure that the finished product meets the client’s specifications and industry regulations.

These quality control measures are essential for delivering high-quality steel products that meet the demanding requirements of various industries. By adhering to rigorous quality assurance processes, steel fabrication shops ensure that their products are precise, durable, and reliable, contributing to the safety and longevity of the structures they support.

Customization

Customization is a hallmark of steel fabrication shops, enabling them to cater to the unique demands of various industries and applications. This ability to create custom steel components and structures based on specific requirements sets steel fabrication shops apart from mass production facilities.

- Uniqueness and Innovation: Steel fabrication shops excel in producing one-of-a-kind steel components and structures that are tailored to the exact specifications and design intent of clients. This allows for innovative solutions that may not be feasible with standardized products.

- Adaptability to Diverse Industries: The ability to customize steel components and structures makes steel fabrication shops adaptable to a wide range of industries, including construction, manufacturing, transportation, and energy. They can create specialized components that meet the unique functional and aesthetic requirements of each industry.

- Meeting Specific Performance Needs: Customization empowers steel fabrication shops to create components and structures that meet specific performance needs. This includes designing for load-bearing capacity, environmental resistance, or aesthetic appeal, ensuring that the final product aligns with the intended purpose.

- Efficient Use of Materials: By customizing steel components and structures, fabrication shops can optimize material usage, reducing waste and ensuring cost-effectiveness. This is particularly valuable for projects with unique shapes or complex geometries.

The ability to create custom steel components and structures based on specific requirements is a key strength of steel fabrication shops. It enables them to deliver innovative, adaptable, and high-performance solutions that cater to the diverse needs of their clients across various industries.

Project Management

In the realm of steel fabrication shops, effective project management plays a crucial role in ensuring the successful execution of projects, from design conception to final delivery. Experienced project managers serve as the backbone of these shops, overseeing every aspect of the fabrication process to ensure that projects are completed on time, within budget, and to the highest standards of quality.

The connection between project management and steel fabrication shops is multifaceted and interdependent. Here are some key aspects that highlight their importance:

- Coordination and Scheduling: Project managers are responsible for coordinating the efforts of various teams involved in steel fabrication, including engineers, fabricators, and quality control personnel. They develop detailed project schedules, ensuring that tasks are completed in the correct sequence and within the allotted timeframes.

- Resource Management: Effective project management involves managing resources efficiently, including materials, equipment, and manpower. Project managers allocate resources strategically to optimize productivity and minimize waste, ensuring that projects are completed cost-effectively.

- Quality Control: Project managers oversee the implementation of quality control measures throughout the fabrication process. They work closely with quality control personnel to ensure that fabricated components meet the required specifications and industry standards, delivering high-quality products to clients.

- Risk Management: Project managers identify and assess potential risks that may arise during the fabrication process. They develop mitigation plans to minimize the impact of these risks, ensuring that projects are completed safely and successfully.

- Client Communication: Project managers serve as the primary point of contact for clients, keeping them informed about project progress, potential challenges, and any necessary adjustments. Effective communication fosters trust and ensures that clients are satisfied with the final product.

In essence, experienced project managers are the conductors of steel fabrication projects, orchestrating the efforts of various teams and resources to deliver high-quality steel components and structures. Their expertise and dedication ensure that projects are executed smoothly, efficiently, and to the complete satisfaction of clients.

Safety

In the realm of steel fabrication shops, safety is paramount. Strict adherence to safety regulations and industry best practices is not merely a compliance issue but a fundamental component that underpins the success and reputation of these facilities. This connection is driven by several key factors:

Protection of Personnel: Steel fabrication involves potentially hazardous operations such as welding, cutting, and heavy machinery operation. Implementing comprehensive safety protocols ensures the well-being of workers, minimizing the risk of accidents, injuries, and occupational hazards.

Prevention of Property Damage: Adhering to safety regulations helps prevent costly property damage, equipment malfunctions, and potential disruptions to operations. By proactively addressing safety concerns, steel fabrication shops can safeguard their assets and minimize downtime.

Quality Assurance: Safety measures contribute to overall quality assurance in steel fabrication. When safety protocols are followed diligently, it creates a disciplined and controlled work environment, reducing errors and improving the reliability of fabricated components.

Legal Compliance: Steel fabrication shops are legally obligated to comply with safety regulations set forth by government agencies. Meeting these requirements not only ensures legal compliance but also demonstrates a commitment to responsible operations and ethical conduct.

Reputation and Trust: A strong safety record is a valuable asset for steel fabrication shops. It fosters trust among clients, partners, and the community, enhancing their reputation as reliable and safety-conscious businesses.

Practical Significance: Understanding the connection between safety and steel fabrication shops is crucial for various stakeholders:

- Workers: Safety protocols protect workers from potential hazards, ensuring a safe and healthy work environment.

- Employers: Investing in safety measures reduces the risk of accidents, injuries, and legal liabilities, ultimately benefiting the business.

- Clients: Choosing steel fabrication shops with a strong safety record provides peace of mind and assurance of quality.

- Community: Adhering to safety regulations safeguards the environment and promotes a positive relationship with the surrounding community.

In conclusion, safety is an indispensable aspect of steel fabrication shops. By embracing strict safety regulations and industry best practices, these facilities prioritize the well-being of their workers, protect their assets, enhance quality, comply with legal requirements, and build a strong reputation. Understanding this connection is essential for all stakeholders involved in the steel fabrication industry.

Key Insights:

| Factor | Key Insight |

|---|---|

| Worker Safety | Protection from hazards, minimizing accidents and injuries. |

| Property Protection | Prevention of equipment damage and operational disruptions. |

| Quality Assurance | Disciplined work environment reduces errors and improves reliability. |

| Legal Compliance | Adherence to government regulations and ethical conduct. |

| Reputation and Trust | Strong safety record enhances reputation and fosters trust among stakeholders. |

Communication

In the realm of steel fabrication shops, effective communication serves as the cornerstone for ensuring the successful execution of projects. Clear understanding of project specifications is paramount, as it lays the foundation for accurate fabrication and timely delivery. This connection is driven by several key factors:

- Accurate Interpretation: Open and transparent communication channels enable architects, engineers, and fabricators to exchange project specifications precisely. This minimizes misinterpretations, reduces the risk of errors, and ensures that the final product aligns with the client’s vision.

- Timely Execution: Effective communication facilitates prompt responses to queries and requests for clarification, expediting the fabrication process. Delays caused by misunderstandings or miscommunications are minimized, ensuring timely project delivery.

- Quality Control: Clear communication allows for ongoing feedback and adjustments throughout the fabrication process. This enables timely identification and rectification of any discrepancies, ensuring that the fabricated components meet the required quality standards.

- Customer Satisfaction: Effective communication fosters a collaborative relationship between steel fabrication shops and their clients. It allows for regular updates, discussions on design modifications, and proactive management of expectations, ultimately enhancing customer satisfaction.

The practical significance of effective communication in steel fabrication shops extends to various stakeholders:

- Fabricators: Clear understanding of project specifications empowers fabricators to execute their tasks efficiently, reducing the likelihood of errors and rework.

- Clients: Effective communication ensures that clients’ expectations are met, fostering trust and long-term relationships with steel fabrication shops.

- Architects and Engineers: Open communication channels allow architects and engineers to provide timely design modifications or clarifications, ensuring that the fabricated components align with the overall project design.

In conclusion, effective communication channels are essential for ensuring clear understanding of project specifications in steel fabrication shops. This connection underpins accurate fabrication, timely delivery, quality control, and customer satisfaction. Recognizing the importance of effective communication enables stakeholders to collaborate seamlessly, resulting in successful project outcomes.

Sustainability

In the realm of steel fabrication shops, sustainability has emerged as a key differentiator, with an increasing emphasis on environmentally friendly practices and the use of sustainable materials. This connection is driven by several important factors:

- Reduced Environmental Impact: Steel fabrication processes can generate significant environmental impacts, including air pollution, water consumption, and waste generation. By adopting sustainable practices, such as energy-efficient technologies, recycling programs, and responsible waste management, steel fabrication shops can minimize their environmental footprint and contribute to a greener future.

- Resource Conservation: Steel is a durable and recyclable material, making it an environmentally friendly choice. Steel fabrication shops that prioritize resource conservation implement closed-loop recycling systems, use recycled steel content in their products, and explore innovative ways to reduce material waste.

- Compliance with Regulations: Stringent environmental regulations are in place to protect the environment and promote sustainable practices. Steel fabrication shops that embrace sustainability demonstrate their commitment to compliance, reducing the risk of fines and legal liabilities.

- Customer Demand: Customers are increasingly seeking products and services that align with their environmental values. Steel fabrication shops that prioritize sustainability can differentiate themselves in the market and attract environmentally conscious clients.

The practical significance of sustainability in steel fabrication shops extends to various stakeholders:

- Fabricators: Sustainable practices can reduce operating costs, improve efficiency, and enhance the company’s reputation as a responsible corporate citizen.

- Clients: Choosing steel fabrication shops with a strong commitment to sustainability ensures that their projects align with their environmental goals and values.

- Community: Steel fabrication shops that prioritize sustainability contribute to a cleaner and healthier environment for the surrounding community.

In conclusion, the connection between sustainability and steel fabrication shops is multifaceted, encompassing environmental protection, resource conservation, regulatory compliance, and customer demand. By embracing sustainable practices and using sustainable materials, steel fabrication shops can reduce their environmental impact, enhance their reputation, and meet the evolving needs of the market.

Innovation

In the competitive landscape of steel fabrication, innovation serves as a driving force, propelling steel fabrication shops to continuously invest in new technologies and techniques. This connection stems from the fundamental need to enhance efficiency, precision, and overall quality in the fabrication process.

- Advanced Automation: Steel fabrication shops are embracing advanced automation technologies, such as robotic welding and CNC (Computer Numerical Control) machines, to automate repetitive and complex tasks. This enhances productivity, minimizes human error, and ensures consistent quality throughout the fabrication process.

- Digitalization and Data Analytics: The integration of digital technologies, including Building Information Modeling (BIM) and data analytics, allows steel fabrication shops to streamline project planning, optimize material usage, and monitor production processes in real-time. This data-driven approach enables data-informed decision-making, leading to increased efficiency and reduced waste.

- Sustainable Innovations: Sustainability is becoming a key driver of innovation in steel fabrication. Shops are exploring eco-friendly technologies, such as energy-efficient equipment and recycled steel materials, to minimize their environmental impact. These sustainable practices not only reduce operating costs but also align with the increasing demand for environmentally responsible products and services.

- Research and Development: Steel fabrication shops are actively involved in research and development to push the boundaries of innovation. They collaborate with universities, research institutions, and industry partners to develop cutting-edge technologies that enhance the performance and durability of fabricated steel components.

The continuous pursuit of innovation in steel fabrication shops offers numerous benefits, including reduced production time, improved product quality, increased cost-effectiveness, and enhanced competitiveness in the market. By embracing new technologies and techniques, steel fabrication shops empower themselves to meet the evolving demands of the industry and deliver high-quality steel structures that meet the most stringent requirements.

Industry Standards

In the realm of steel fabrication, adherence to industry standards is paramount, serving as a cornerstone for quality, safety, and reliability. Steel fabrication shops that comply with industry standards demonstrate their commitment to excellence, ensuring that their products and services meet the highest levels of performance and safety.

-

ISO 9001: Quality Management System

ISO 9001 is an internationally recognized quality management system standard that outlines the requirements for a comprehensive quality management system. Compliance with ISO 9001 indicates that a steel fabrication shop has implemented a robust system for managing its processes, ensuring consistent quality and customer satisfaction throughout all aspects of its operations. -

AWS D1.1: Structural Welding Code – Steel

AWS D1.1 is a code developed by the American Welding Society (AWS) that provides a set of standards for welding structural steel. Compliance with AWS D1.1 ensures that steel fabrication shops employ proper welding techniques, procedures, and qualifications, resulting in safe and reliable welded connections. -

Benefits of Compliance

Compliance with industry standards offers numerous benefits for steel fabrication shops, including enhanced quality control, improved safety, increased customer confidence, and a competitive advantage in the market. By adhering to these standards, shops demonstrate their commitment to quality and safety, which translates into a reputation for excellence and reliability. -

Implications for Steel Fabrication Shops

Achieving and maintaining compliance with industry standards requires a significant investment of time, resources, and effort from steel fabrication shops. It involves implementing and maintaining a quality management system, training staff to meet welding code requirements, and undergoing regular audits to ensure ongoing compliance.

In conclusion, compliance with industry standards such as ISO 9001 and AWS D1.1 is a critical aspect of steel fabrication, signifying a commitment to quality, safety, and customer satisfaction. By adhering to these standards, steel fabrication shops distinguish themselves as reliable and trustworthy providers of high-quality steel products and services, meeting the demands of a discerning market.

Frequently Asked Questions about Steel Fabrication Shops

This section addresses frequently asked questions and misconceptions regarding steel fabrication shops, providing informative answers to enhance your understanding of their operations and services.

Question 1: What services do steel fabrication shops typically offer?

Steel fabrication shops provide a wide range of services, including cutting, bending, welding, and assembling steel components. They can create custom steel structures, such as beams, columns, and stairs, based on specific design requirements.

Question 2: What is the typical lead time for a steel fabrication project?

The lead time for a steel fabrication project varies depending on the complexity of the design, the availability of materials, and the shop’s workload. However, most shops aim to complete projects within a few weeks to several months.

Question 3: How do steel fabrication shops ensure the quality of their products?

Reputable steel fabrication shops adhere to strict quality control measures throughout the fabrication process. They use certified materials, employ skilled fabricators, and conduct thorough inspections to ensure that their products meet industry standards and customer specifications.

Question 4: What factors should be considered when choosing a steel fabrication shop?

When selecting a steel fabrication shop, consider factors such as their experience, reputation, certifications, and ability to meet your specific requirements. It is also important to inquire about their quality control procedures and customer service.

Question 5: Are steel fabrication shops environmentally conscious?

Many steel fabrication shops are committed to sustainable practices and minimizing their environmental impact. They may use recycled materials, implement energy-efficient processes, and adhere to environmental regulations to reduce their carbon footprint.

Question 6: How can I find a reliable steel fabrication shop near me?

To find a reliable steel fabrication shop near you, search online directories, ask for recommendations from industry professionals, or visit local trade shows and events. You can also check for certifications and positive customer reviews to assess their credibility.

Summary: Steel fabrication shops play a crucial role in various industries, offering a range of services to meet diverse steel fabrication needs. By choosing a reputable shop with a proven track record and commitment to quality, you can ensure the successful execution of your steel fabrication projects.

Transition: To delve deeper into the capabilities and advantages of steel fabrication shops, let’s explore some key aspects that set them apart.

Tips for Working with Steel Fabrication Shops

To ensure a successful collaboration with steel fabrication shops and achieve optimal results, consider the following tips:

Tip 1: Provide Clear and Detailed Specifications: Communicate your project requirements thoroughly, including specific dimensions, material preferences, and any necessary certifications. Clear specifications minimize errors and ensure that the fabricated components meet your exact needs.

Tip 2: Choose a Reputable and Experienced Shop: Research and select a steel fabrication shop with a proven track record of delivering high-quality work. Look for shops certified by industry organizations and with positive customer reviews.

Tip 3: Establish Clear Communication Channels: Open and timely communication is crucial. Establish clear communication channels with the fabrication shop to discuss project updates, address any concerns, and ensure that everyone is on the same page.

Tip 4: Consider Lead Times and Capacity: Be aware of the lead times involved in steel fabrication and plan accordingly. Inquire about the shop’s capacity and workload to avoid potential delays.

Tip 5: Foster a Collaborative Partnership: Approach the relationship with the steel fabrication shop as a collaborative partnership. Share your project goals and objectives, and be open to their suggestions and expertise.

Tip 6: Conduct Regular Inspections: Schedule regular inspections throughout the fabrication process to ensure that the work is progressing as expected. This allows for early identification and correction of any potential issues.

Tip 7: Prioritize Safety: Safety should be a top priority. Ensure that the steel fabrication shop adheres to industry safety standards and follows proper protocols to minimize risks.

Tip 8: Value Quality over Cost: While cost is a factor, prioritize quality when selecting a steel fabrication shop. A reputable shop may charge slightly more, but their expertise and commitment to quality will provide long-term benefits.

Summary: By following these tips, you can effectively collaborate with steel fabrication shops, ensuring that your projects are completed to the highest standards of quality, safety, and efficiency.

Transition: To further enhance your knowledge and understanding of steel fabrication shops, let’s delve into their capabilities and the benefits they offer.

Conclusion

Steel fabrication shops stand as pillars of the construction, manufacturing, and infrastructure industries, transforming raw steel into intricate components and structures that shape our built environment. Through their expertise in cutting, bending, welding, and assembly, these shops play a vital role in realizing ambitious architectural designs, enhancing the durability of infrastructure, and driving technological advancements.

As technology continues to advance, steel fabrication shops are embracing innovation, incorporating advanced equipment, digitalization, and sustainable practices into their operations. This unwavering pursuit of excellence ensures that they remain at the forefront of the industry, delivering high-quality steel products that meet the evolving demands of a modern world.

The future of steel fabrication holds immense promise. By embracing collaboration, investing in research and development, and maintaining a commitment to quality and safety, steel fabrication shops will continue to shape the skylines of our cities, strengthen the foundations of our industries, and contribute to a more sustainable and resilient built environment.