Wondering what a steel fabrication supervisor does? Steel fabrication supervisors oversee the production of steel structures, ensuring that they meet specifications and quality standards. They manage a team of workers and coordinate with other departments to ensure that projects are completed on time and within budget.

Editor’s Note: Steel fabrication is a critical industry that plays a vital role in the construction of buildings, bridges, and other structures. Steel fabrication supervisors play a key role in ensuring that these structures are safe and meet the highest standards of quality.

To help you understand the role of a steel fabrication supervisor, we’ve put together this comprehensive guide. We’ll cover the following topics:

- The key responsibilities of a steel fabrication supervisor

- The qualifications and experience required to become a steel fabrication supervisor

- The salary and benefits of a steel fabrication supervisor

- The job outlook for steel fabrication supervisors

Whether you’re considering a career as a steel fabrication supervisor or you’re simply curious about this important role, we encourage you to read on.

Key Responsibilities of a Steel Fabrication Supervisor

Steel fabrication supervisors have a wide range of responsibilities, including:

- Planning and scheduling production

- Supervising a team of workers

- Ensuring that products meet specifications

- Coordinating with other departments

- Maintaining a safe work environment

Steel fabrication supervisors must have a strong understanding of steel fabrication processes and techniques. They must also be able to read and interpret blueprints and drawings. Excellent communication and interpersonal skills are also essential.

Qualifications and Experience Required to Become a Steel Fabrication Supervisor

To become a steel fabrication supervisor, you typically need a high school diploma or equivalent. Some employers may require a college degree in a related field, such as engineering or construction management. Prior experience in steel fabrication is also typically required.

Many steel fabrication supervisors start their careers as welders or other entry-level positions. They then work their way up to supervisory positions as they gain experience and knowledge.

Salary and Benefits of a Steel Fabrication Supervisor

The salary of a steel fabrication supervisor varies depending on experience, education, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for all supervisors of production and operating workers was $64,960 in May 2020. The lowest 10 percent earned less than $35,820, and the highest 10 percent earned more than $114,320.

In addition to salary, steel fabrication supervisors may also receive benefits such as health insurance, paid time off, and a retirement plan.

Job Outlook for Steel Fabrication Supervisors

The job outlook for steel fabrication supervisors is expected to be good over the next decade. The demand for steel is expected to grow as the construction industry continues to recover. This will lead to increased demand for steel fabricators and supervisors.

Steel fabrication supervisors with experience in welding and other advanced fabrication techniques are expected to be in high demand.

Conclusion

Steel fabrication supervisors play a vital role in the construction industry. They ensure that steel structures are safe and meet the highest standards of quality. If you’re interested in a career in steel fabrication, there are many opportunities available.

We hope this guide has been helpful. If you have any questions, please don’t hesitate to contact us.

Steel Fabrication Supervisor Job Description

Steel fabrication supervisors play a vital role in the construction industry. They ensure that steel structures are safe and meet the highest standards of quality. To be successful in this role, there are several key aspects that are essential:

- Planning and scheduling: Steel fabrication supervisors must be able to plan and schedule production efficiently to meet deadlines.

- Supervising and motivating: They must be able to supervise and motivate a team of workers to achieve high levels of productivity.

- Technical expertise: They must have a strong technical understanding of steel fabrication processes and techniques.

- Communication and interpersonal skills: They must be able to communicate effectively with workers, clients, and other stakeholders.

- Safety: They must be committed to safety and maintaining a safe work environment.

- Problem-solving: They must be able to solve problems quickly and effectively to keep production on track.

- Attention to detail: They must be able to pay close attention to detail to ensure that all products meet specifications.

These are just a few of the key aspects that are essential for steel fabrication supervisors. By understanding these aspects and developing the necessary skills, you can increase your chances of success in this rewarding career.

Planning and scheduling

Planning and scheduling are essential aspects of a steel fabrication supervisor’s job. Supervisors must be able to develop and implement production plans that ensure that projects are completed on time and within budget. This involves:

- Assessing project requirements: Supervisors must first assess the requirements of each project, including the type of steel needed, the dimensions of the product, and the delivery deadline.

- Developing a production plan: Once the project requirements have been assessed, the supervisor must develop a production plan that outlines the steps involved in fabricating the product. This plan should include timelines for each step, as well as the resources that will be needed.

- Scheduling production: Once the production plan has been developed, the supervisor must schedule the production process. This involves assigning tasks to workers, coordinating the delivery of materials, and ensuring that all deadlines are met.

- Monitoring progress: Supervisors must monitor the progress of production to ensure that it is on track. This involves tracking the completion of tasks, identifying any potential delays, and taking corrective action as needed.

Effective planning and scheduling are essential for the success of any steel fabrication project. Supervisors who are able to develop and implement efficient production plans can help to ensure that projects are completed on time, within budget, and to the highest standards of quality.

Supervising and motivating

Supervising and motivating a team of workers is an essential aspect of a steel fabrication supervisor’s job. Supervisors must be able to create a positive and productive work environment in which workers are motivated to perform at their best. This involves:

- Setting clear expectations: Supervisors must set clear expectations for workers and provide them with the resources and support they need to succeed.

- Providing feedback: Supervisors must provide workers with regular feedback on their performance, both positive and negative. This feedback should be specific and actionable, and it should help workers to improve their performance.

- Recognizing and rewarding success: Supervisors must recognize and reward workers for their achievements. This can be done through verbal praise, written recognition, or financial rewards.

- Creating a positive work environment: Supervisors must create a positive work environment in which workers feel valued and respected. This involves fostering a sense of teamwork and cooperation, and it also involves providing workers with a safe and healthy workplace.

Supervisors who are able to effectively supervise and motivate their teams can help to improve productivity, reduce turnover, and create a more positive work environment. This can lead to increased profits for the company and a more rewarding career for the supervisor.

Here are some real-life examples of how steel fabrication supervisors have used their skills to improve productivity and motivate their teams:

- One supervisor implemented a new training program that helped workers to improve their skills and knowledge. This led to a significant increase in productivity and a decrease in errors.

- Another supervisor created a new system for tracking worker performance. This system helped workers to identify areas where they could improve, and it also helped the supervisor to provide more targeted feedback.

- A third supervisor implemented a new rewards program that recognized workers for their achievements. This program helped to boost morale and motivation, and it also led to an increase in productivity.

These are just a few examples of how steel fabrication supervisors can use their skills to improve productivity and motivate their teams. By understanding the importance of supervision and motivation, supervisors can create a more positive and productive work environment for everyone.

Technical expertise

Technical expertise is essential for steel fabrication supervisors. They must have a strong understanding of steel fabrication processes and techniques to be able to effectively supervise and manage their teams. This includes knowledge of:

- Different types of steel and their properties

- Welding and cutting techniques

- Fabrication equipment and machinery

- Quality control and inspection procedures

- Safety regulations and best practices

Supervisors with a strong technical understanding can ensure that their teams are using the correct techniques and equipment to produce high-quality products. They can also identify and correct potential problems before they become major issues. This can help to improve productivity, reduce costs, and ensure the safety of workers.

Here are some real-life examples of how steel fabrication supervisors have used their technical expertise to improve their operations:

- One supervisor implemented a new welding technique that reduced the amount of time it took to weld a particular component. This led to a significant increase in productivity.

- Another supervisor identified a problem with a piece of equipment that was causing defects in the products. By working with the manufacturer, the supervisor was able to get the equipment repaired and prevent further defects.

- A third supervisor developed a new quality control procedure that helped to identify and correct defects before they reached the customer. This led to a decrease in customer complaints and an increase in customer satisfaction.

These are just a few examples of how steel fabrication supervisors can use their technical expertise to improve their operations. By understanding the importance of technical expertise, supervisors can develop the skills and knowledge they need to be successful in their roles.

Communication and interpersonal skills

Communication and interpersonal skills are essential for steel fabrication supervisors. They must be able to communicate effectively with workers, clients, and other stakeholders to ensure that projects are completed on time, within budget, and to the highest standards of quality.

- Active listening: Supervisors must be able to listen actively to workers, clients, and other stakeholders to understand their needs and concerns. This allows them to build strong relationships and develop trust.

- Clear communication: Supervisors must be able to communicate clearly and concisely with workers, clients, and other stakeholders. This ensures that everyone is on the same page and that projects are completed according to plan.

- Conflict resolution: Supervisors must be able to resolve conflicts effectively. This involves identifying the root cause of the conflict, developing a plan to resolve it, and communicating the plan to all parties involved.

- Teamwork: Supervisors must be able to work effectively with others as part of a team. This involves building strong relationships with team members, motivating them to perform at their best, and resolving conflicts.

Supervisors who are able to develop strong communication and interpersonal skills can create a positive and productive work environment. This can lead to increased productivity, reduced turnover, and improved customer satisfaction.

Safety

Safety, or a commitment to safety, is an essential aspect of a steel fabrication supervisor job description. Steel fabrication involves working with heavy machinery and materials, so it is important for supervisors to be aware of the potential hazards and to take steps to prevent accidents. Supervisors must be able to identify and assess risks, develop and implement safety procedures, and train workers on safety protocols.

A safe work environment benefits both the company and the employees. For the company, a safe work environment can reduce the risk of accidents, which can lead to lost productivity, increased insurance costs, and damage to equipment. For employees, a safe work environment can prevent injuries and illnesses, which can lead to lost wages, pain and suffering, and even death.

Steel fabrication supervisors can demonstrate their commitment to safety by:

- Developing and implementing a comprehensive safety program

- Providing safety training to workers

- Enforcing safety rules and regulations

- Inspecting the workplace for hazards

- Investigating accidents and incidents

By understanding the importance of safety and by taking steps to create a safe work environment, steel fabrication supervisors can help to protect their workers and their company.

Here are some real-life examples of how steel fabrication supervisors have demonstrated their commitment to safety:

- One supervisor implemented a new safety program that reduced the number of accidents at his plant by 50%.

- Another supervisor developed a new training program that helped workers to identify and avoid hazards.

- A third supervisor worked with his team to develop a new safety device that prevented a serious accident.

These are just a few examples of how steel fabrication supervisors can make a difference in the safety of their workplaces. By understanding the importance of safety and by taking steps to create a safe work environment, supervisors can help to protect their workers and their company.

Problem-solving

Problem-solving is a critical skill for steel fabrication supervisors. They must be able to identify and solve problems quickly and effectively to keep production on track. This involves:

- Identifying the problem: The first step in solving a problem is to identify the problem. This may seem obvious, but it is often the most difficult step. Supervisors must be able to gather information, analyze the situation, and identify the root cause of the problem.

- Developing a solution: Once the problem has been identified, the supervisor must develop a solution. This may involve brainstorming with the team, researching possible solutions, or consulting with experts. The supervisor must then evaluate the potential solutions and select the best one.

- Implementing the solution: Once a solution has been selected, the supervisor must implement it. This may involve making changes to the production process, training workers on new procedures, or purchasing new equipment. The supervisor must also monitor the implementation of the solution to ensure that it is working as intended.

- Evaluating the solution: Once the solution has been implemented, the supervisor must evaluate its effectiveness. This may involve tracking key metrics, such as production output, quality, and customer satisfaction. The supervisor must then make any necessary adjustments to the solution to ensure that it is meeting the desired outcomes.

Supervisors who are able to solve problems quickly and effectively can help to improve productivity, reduce costs, and ensure the safety of workers. Here are some real-life examples of how steel fabrication supervisors have used their problem-solving skills to improve their operations:

- One supervisor identified a problem with a piece of equipment that was causing delays in production. The supervisor worked with the manufacturer to develop a solution that fixed the problem and reduced production delays by 50%.

- Another supervisor identified a problem with the quality of the welds on a particular product. The supervisor worked with the welding team to develop a new welding procedure that improved the quality of the welds and reduced the number of defects.

- A third supervisor identified a problem with the safety of a particular work area. The supervisor worked with the safety team to develop a new safety procedure that reduced the risk of accidents in the work area.

These are just a few examples of how steel fabrication supervisors can use their problem-solving skills to improve their operations. By understanding the importance of problem-solving and by developing their problem-solving skills, supervisors can help to create a more efficient, productive, and safe work environment.

Attention to detail

Attention to detail is an essential quality for steel fabrication supervisors. They must be able to carefully inspect products to ensure that they meet all specifications. This is important for several reasons:

- Safety: Steel fabrication products are often used in critical applications, such as bridges and buildings. It is important to ensure that these products are free of defects that could cause safety hazards.

- Quality: Customers expect steel fabrication products to meet certain quality standards. Supervisors must be able to identify and correct any defects that could affect the quality of the product.

- Cost: Defects in steel fabrication products can be costly to repair or replace. Supervisors who pay close attention to detail can help to prevent these costs.

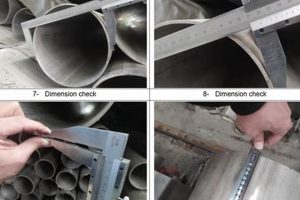

Steel fabrication supervisors can use a variety of tools to help them pay attention to detail. These tools include:

- Checklists: Checklists can help supervisors to ensure that they have inspected all aspects of a product.

- Measuring tools: Measuring tools can help supervisors to verify that products meet the correct dimensions.

- Magnifying glasses: Magnifying glasses can help supervisors to identify small defects that might otherwise be missed.

Supervisors who are able to pay close attention to detail can help to ensure that steel fabrication products are safe, high-quality, and cost-effective.

Here are some real-life examples of how steel fabrication supervisors have used their attention to detail to improve their operations:

- One supervisor identified a small crack in a steel beam that was being used to build a bridge. The supervisor ordered the beam to be replaced, which prevented a potential disaster.

- Another supervisor identified a misalignment in a steel frame that was being used to build a new building. The supervisor corrected the misalignment, which prevented the building from collapsing.

- A third supervisor identified a small defect in a steel plate that was being used to build a pressure vessel. The supervisor rejected the plate, which prevented a potential explosion.

These are just a few examples of how steel fabrication supervisors can use their attention to detail to improve their operations. By understanding the importance of attention to detail and by developing their attention to detail skills, supervisors can help to create a more safe, efficient, and productive work environment.

FAQs Regarding Steel Fabrication Supervisor Job Description

This section addresses frequently asked questions about steel fabrication supervisor job descriptions, providing concise and informative answers to common concerns and misconceptions.

Question 1: What are the primary responsibilities of a steel fabrication supervisor?

Steel fabrication supervisors oversee the production of steel structures, ensuring compliance with specifications and quality standards. They manage teams of workers, coordinate with other departments, and prioritize timely project completion within budget constraints.

Question 2: What qualifications are typically required to become a steel fabrication supervisor?

Typically, a high school diploma or equivalent is required. Some employers may seek candidates with college degrees in related fields like engineering or construction management. Prior experience in steel fabrication is generally a prerequisite, with many supervisors starting their careers as welders or in other entry-level positions before advancing to supervisory roles.

Question 3: What is the average salary range for steel fabrication supervisors?

The salary of a steel fabrication supervisor can vary based on experience, education, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for all supervisors of production and operating workers was $64,960 in May 2020, with the lowest 10 percent earning less than $35,820 and the highest 10 percent earning more than $114,320.

Question 4: What is the job outlook for steel fabrication supervisors?

The job outlook for steel fabrication supervisors is projected to be favorable over the next decade. The demand for steel is expected to rise as the construction industry continues to recover, leading to increased demand for steel fabricators and supervisors. Those with experience in welding and advanced fabrication techniques are likely to be in high demand.

Question 5: What are the key skills and qualities that successful steel fabrication supervisors possess?

Effective steel fabrication supervisors possess a combination of technical expertise, leadership abilities, and attention to detail. They have a strong understanding of steel fabrication processes and techniques, can effectively supervise and motivate teams, and are committed to maintaining a safe and productive work environment.

Question 6: What are the potential career advancement opportunities for steel fabrication supervisors?

With experience and demonstrated competence, steel fabrication supervisors may advance to roles with increased responsibilities, such as production manager or plant manager. Some may also choose to pursue specialized certifications or further education to enhance their career prospects.

These FAQs provide a comprehensive overview of the steel fabrication supervisor job description, encompassing responsibilities, qualifications, salary expectations, job outlook, essential skills, and career advancement opportunities. By understanding these aspects, individuals can make informed decisions about pursuing a career in this field.

Transition to the next article section: Exploring the educational pathways and training programs available for aspiring steel fabrication supervisors.

Steel Fabrication Supervisor Job Description

To excel in a steel fabrication supervisor role, consider the following essential tips:

Tip 1: Master Technical Expertise and Industry Knowledge

Possess a thorough understanding of steel fabrication processes, techniques, and industry best practices. Stay updated on advancements and innovations in the field to enhance decision-making and ensure optimal production outcomes.

Tip 2: Cultivate Effective Leadership and Communication Skills

Motivate and guide your team effectively by fostering open communication, setting clear expectations, and providing constructive feedback. Excellent communication skills enable seamless collaboration and efficient project execution.

Tip 3: Prioritize Workplace Safety and Compliance

Maintain a safe and compliant work environment by adhering to industry regulations and implementing comprehensive safety protocols. Regularly assess potential hazards and implement measures to mitigate risks, ensuring the well-being of your team.

Tip 4: Embrace Problem-Solving and Continuous Improvement

Anticipate and proactively resolve challenges by employing critical thinking and analytical skills. Foster a culture of continuous improvement by seeking feedback, implementing innovative solutions, and optimizing processes.

Tip 5: Develop Strong Attention to Detail and Quality Assurance

Ensure adherence to specifications and quality standards by maintaining meticulous attention to detail. Implement rigorous inspection procedures and empower your team to prioritize quality throughout the fabrication process.

Tip 6: Stay Abreast of Industry Trends and Technology

Keep pace with emerging technologies and industry trends to enhance productivity and efficiency. Explore new techniques, materials, and equipment that can optimize fabrication processes and improve overall performance.

Tip 7: Foster a Collaborative and Supportive Team Environment

Create a positive and supportive work culture where teamwork and collaboration thrive. Encourage open communication, recognize individual contributions, and provide opportunities for professional development to enhance team morale and productivity.

Tip 8: Seek Professional Development and Certifications

Continuously enhance your knowledge and skills by pursuing professional development opportunities. Obtain industry-recognized certifications to demonstrate your commitment to excellence and stay competitive in the field.

Incorporating these tips into your approach can significantly contribute to your success as a steel fabrication supervisor. By prioritizing technical expertise, effective leadership, workplace safety, problem-solving, attention to detail, industry knowledge, team collaboration, and professional development, you can excel in this demanding yet rewarding role.

Steel Fabrication Supervisor Job Description

Throughout this exploration of the steel fabrication supervisor job description, we have delved into the intricacies of this crucial role within the steel fabrication industry. From the essential responsibilities and qualifications to the rewarding career path and essential tips for success, we have aimed to provide a comprehensive overview of this multifaceted position.

Effective steel fabrication supervisors serve as the backbone of successful fabrication operations, ensuring the seamless production of high-quality steel structures. Their expertise, leadership, and commitment to safety are indispensable in meeting the demands of modern construction and industrial projects. As the industry continues to evolve, the role of steel fabrication supervisors will remain vital, shaping the built environment and driving innovation.