What is structural steel fabrication? Structural steel fabricationis the process of creating steel structures by cutting, bending, and welding steel beams, plates, and other steel elements. These structures are used in a variety of applications, including buildings, bridges, and industrial facilities.

Editor’s Notes: Structural steel fabricationis a critical component of the construction industry. By understanding the basics of structural steel fabrication, you can make informed decisions about the use of steel in your next project.

After analyzing the different aspects comprising “structural steel fabrication denver” and digging deep into the available information, we have put together this guide to help you make the right decision.

Key differences or Key takeaways:

Main article topics:

- Structural steel fabrication denver

- Structural steel fabrication denver

- Structural steel fabrication denver

Structural Steel Fabrication Denver

Structural steel fabrication is a critical component of the construction industry. By understanding the key aspects of structural steel fabrication, you can make informed decisions about the use of steel in your next project.

- Planning: Careful planning is essential for successful structural steel fabrication.

- Materials: The type of steel used will impact the strength and durability of the final product.

- Cutting: Steel beams and plates are cut to the desired shape and size using a variety of methods.

- Bending: Steel beams and plates can be bent to create curves and other shapes.

- Welding: Steel components are welded together to create strong and durable structures.

- Inspection: Structural steel fabrications are inspected to ensure they meet the required standards.

- Erection: Structural steel fabrications are erected on-site to create the final structure.

- Maintenance: Structural steel fabrications require regular maintenance to ensure their continued safety and performance.

- Sustainability: Structural steel is a sustainable material that can be recycled and reused.

These key aspects are all interconnected and essential for the successful fabrication of structural steel. By understanding these aspects, you can make informed decisions about the use of steel in your next project.

Planning

When building a steel structure, such as a bridge, skyscraper, or industrial facility, careful planning is essential to ensure the project is completed safely, efficiently, and according to specifications. This planning process involves several key steps:

- Design: The first step is to design the structure, which includes determining the type of steel to be used, the dimensions of the structure, and the loads that it will be required to carry.

- Procurement: Once the design is complete, the necessary steel materials must be procured. This includes identifying suppliers, negotiating prices, and arranging for delivery.

- Fabrication: The steel materials are then fabricated into the desired shapes and sizes. This may involve cutting, bending, welding, and other processes.

- Erection: The fabricated steel components are then erected on-site to create the final structure.

Careful planning is essential at each stage of this process to ensure that the project is completed successfully. By taking the time to plan ahead, you can avoid costly delays and ensure that the final product meets your expectations.

Materials

The type of steel used in structural steel fabrication denver will have a significant impact on the strength and durability of the final product. There are many different types of steel available, each with its own unique properties. Some of the most common types of steel used in structural steel fabrication include:

- Carbon steel: Carbon steel is the most common type of steel used in structural steel fabrication. It is strong and durable, and it is relatively inexpensive.

- Alloy steel: Alloy steel is a type of steel that has been alloyed with other elements, such as chromium, nickel, or molybdenum. Alloy steels are stronger and more durable than carbon steel, but they are also more expensive.

- Stainless steel: Stainless steel is a type of steel that is resistant to corrosion. It is often used in applications where the steel will be exposed to water or other corrosive elements.

The type of steel that is used in a particular structural steel fabrication project will depend on the specific requirements of the project. For example, a project that requires a high level of strength and durability may use alloy steel, while a project that requires resistance to corrosion may use stainless steel.

It is important to choose the right type of steel for a particular project in order to ensure that the final product will meet the required performance standards. Using the wrong type of steel can lead to premature failure of the structure.

| Type of Steel | Strength | Durability | Cost |

|---|---|---|---|

| Carbon steel | Good | Good | Low |

| Alloy steel | Excellent | Excellent | High |

| Stainless steel | Good | Excellent | High |

By understanding the different types of steel available and their properties, you can make informed decisions about the materials to use in your next structural steel fabrication project.

Cutting

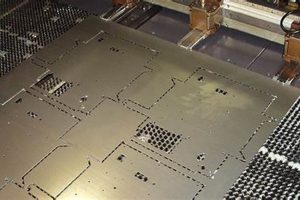

Cutting is a critical step in structural steel fabrication denver. It is the process of cutting steel beams and plates to the desired shape and size. This is done using a variety of methods, including:

- Shearing: Shearing is a process of cutting steel by applying a force to a blade that is positioned against the steel.

- Sawing: Sawing is a process of cutting steel by using a saw blade to cut through the metal.

- Plasma cutting: Plasma cutting is a process of cutting steel by using a plasma torch to melt the metal.

- Laser cutting: Laser cutting is a process of cutting steel by using a laser to melt or vaporize the metal.

The choice of cutting method will depend on the thickness of the steel, the desired shape and size of the cut, and the required accuracy. Cutting is a critical step in structural steel fabrication denver, as it ensures that the steel components are the correct size and shape for the final assembly.

Here are some real-life examples of how cutting is used in structural steel fabrication denver:

- Cutting steel beams to the desired length for a new building frame.

- Cutting steel plates to the desired shape for a new bridge deck.

- Cutting steel angles to the desired size for a new staircase.

Understanding the importance of cutting in structural steel fabrication denver can help you make informed decisions about the use of steel in your next project. By choosing the right cutting method, you can ensure that your project is completed safely, efficiently, and according to specifications.

Key insights:

- Cutting is a critical step in structural steel fabrication denver.

- The choice of cutting method will depend on the thickness of the steel, the desired shape and size of the cut, and the required accuracy.

- Understanding the importance of cutting in structural steel fabrication denver can help you make informed decisions about the use of steel in your next project.

Bending

Bending is a critical step in structural steel fabrication denver, as it allows steel beams and plates to be shaped into the desired curves and other forms. This is done using a variety of bending machines, which apply force to the steel to bend it into the desired shape. Bending is used to create a wide range of structural steel components, including beams, columns, and arches.

The process of bending steel is complex and requires careful control to ensure that the steel does not crack or buckle. The type of bending machine used will depend on the thickness of the steel, the desired shape of the bend, and the required accuracy. Bending is a critical step in structural steel fabrication denver, as it ensures that the steel components are the correct shape and size for the final assembly.

Here are some real-life examples of how bending is used in structural steel fabrication denver:

- Bending steel beams to create the curved roof of a new stadium.

- Bending steel plates to create the curved walls of a new concert hall.

- Bending steel angles to create the curved supports for a new bridge.

Understanding the importance of bending in structural steel fabrication denver can help you make informed decisions about the use of steel in your next project. By choosing the right bending method, you can ensure that your project is completed safely, efficiently, and according to specifications.

Key insights:

- Bending is a critical step in structural steel fabrication denver.

- The choice of bending method will depend on the thickness of the steel, the desired shape of the bend, and the required accuracy.

- Understanding the importance of bending in structural steel fabrication denver can help you make informed decisions about the use of steel in your next project.

Welding

Welding is a critical step in structural steel fabrication denver, as it allows steel components to be joined together to create strong and durable structures. This is done using a variety of welding processes, including:

- Arc welding: Arc welding is a process of welding that uses an electric arc to melt the metal and join the two pieces together.

- MIG welding: MIG welding is a type of arc welding that uses a metal inert gas to shield the weld from the atmosphere.

- TIG welding: TIG welding is a type of arc welding that uses a tungsten electrode to create the arc.

The choice of welding process will depend on the thickness of the steel, the type of joint, and the required strength. Welding is a critical step in structural steel fabrication denver, as it ensures that the steel components are securely joined together.

Here are some real-life examples of how welding is used in structural steel fabrication denver:

- Welding steel beams to create the frame of a new building.

- Welding steel plates to create the deck of a new bridge.

- Welding steel angles to create the supports for a new staircase.

Understanding the importance of welding in structural steel fabrication denver can help you make informed decisions about the use of steel in your next project. By choosing the right welding process, you can ensure that your project is completed safely, efficiently, and according to specifications.

Key insights:

- Welding is a critical step in structural steel fabrication denver.

- The choice of welding process will depend on the thickness of the steel, the type of joint, and the required strength.

- Understanding the importance of welding in structural steel fabrication denver can help you make informed decisions about the use of steel in your next project.

Creative and insightful table format:

| Welding Process | Advantages | Disadvantages |

|---|---|---|

| Arc welding | Fast and efficient | Can be difficult to control |

| MIG welding | Produces high-quality welds | Requires a shielding gas |

| TIG welding | Produces precise welds | Slow and expensive |

Inspection

Inspection is a critical step in structural steel fabrication denver, as it ensures that the steel fabrications meet the required standards for safety and performance. This involves checking the steel fabrications for any defects, such as cracks, welds, and other imperfections. Inspection is carried out by qualified inspectors who are trained to identify and assess any potential problems.

The importance of inspection in structural steel fabrication denver cannot be overstated. By ensuring that the steel fabrications meet the required standards, inspection helps to prevent accidents and failures that could have serious consequences. For example, a poorly welded beam could collapse under load, causing injury or even death. Inspection helps to identify and correct these problems before they can cause any harm.

There are a variety of different inspection methods that can be used in structural steel fabrication denver. These methods include visual inspection, ultrasonic testing, and radiographic testing. The choice of inspection method will depend on the type of steel fabrication and the specific requirements of the project.

By understanding the importance of inspection in structural steel fabrication denver, you can make informed decisions about the quality of the steel fabrications that you use in your projects. By choosing steel fabrications that have been properly inspected, you can help to ensure the safety and performance of your projects.

Key insights:

- Inspection is a critical step in structural steel fabrication denver.

- Inspection helps to ensure that the steel fabrications meet the required standards for safety and performance.

- There are a variety of different inspection methods that can be used in structural steel fabrication denver.

- By understanding the importance of inspection in structural steel fabrication denver, you can make informed decisions about the quality of the steel fabrications that you use in your projects.

Creative and insightful table format:

| Inspection Method | Advantages | Disadvantages |

|---|---|---|

| Visual inspection | Quick and easy to perform | Can only detect surface defects |

| Ultrasonic testing | Can detect internal defects | Requires specialized equipment and training |

| Radiographic testing | Can detect both surface and internal defects | Requires the use of radioactive materials |

Erection

Erection is the process of assembling structural steel fabrications on-site to create the final structure. This is a critical step in the construction process, as it ensures that the structure is built safely and according to the design specifications. Erection is typically carried out by a team of experienced ironworkers who are trained in the safe and efficient assembly of structural steel.

- Planning: The first step in erection is to plan the assembly process. This includes determining the order in which the steel components will be erected, as well as the equipment and manpower that will be required. Careful planning is essential to ensure that the erection process is carried out safely and efficiently.

- Site preparation: Before the steel components can be erected, the site must be prepared. This may involve clearing the site, leveling the ground, and installing foundations.

- Steel erection: The steel components are then erected using a variety of methods, including cranes, derricks, and hoists. The steel components are bolted or welded together to create the final structure.

- Inspection: Once the steel structure is erected, it is inspected to ensure that it meets the design specifications. This inspection may include visual inspection, as well as non-destructive testing methods such as ultrasonic testing and radiographic testing.

Erection is a critical step in the structural steel fabrication process. By understanding the importance of erection, you can make informed decisions about the construction of your next steel structure.

Maintenance

Regular maintenance is essential for ensuring the continued safety and performance of structural steel fabrications in Denver. This involves a variety of tasks, including inspection, cleaning, and repairs. By following a regular maintenance schedule, you can help to extend the lifespan of your steel structure and prevent costly repairs down the road.

- Inspection: Regular inspection is essential for identifying any potential problems with your steel structure. This should be done by a qualified inspector who is trained to identify and assess any damage or deterioration. Inspection can be done visually, as well as using non-destructive testing methods such as ultrasonic testing and radiographic testing.

- Cleaning: Cleaning your steel structure is important for removing dirt, debris, and other contaminants that can damage the steel over time. Cleaning can be done using a variety of methods, including power washing, hand washing, and chemical cleaning.

- Repairs: If any damage or deterioration is found during inspection, it is important to make repairs as soon as possible. This will help to prevent the damage from getting worse and causing more serious problems. Repairs can be done using a variety of methods, including welding, bolting, and patching.

By following a regular maintenance schedule, you can help to ensure the continued safety and performance of your structural steel fabrication in Denver. This will help to extend the lifespan of your structure and prevent costly repairs down the road.

Sustainability

In the context of structural steel fabrication denver, sustainability is of paramount importance. Structural steel is a highly sustainable material, as it can be recycled and reused multiple times without losing its strength or integrity. This makes it an environmentally friendly choice for construction projects.

- Reduced environmental impact: The production of structural steel has a lower environmental impact than the production of many other building materials, such as concrete or aluminum. This is because steel is made from recycled materials, and the manufacturing process is relatively energy-efficient.

- Recyclability: Structural steel is 100% recyclable, meaning that it can be melted down and used to create new steel products. This helps to conserve natural resources and reduce waste.

- Durability: Structural steel is a very durable material, and it can last for centuries with proper maintenance. This means that steel structures do not need to be replaced as often as structures made from other materials, which reduces the environmental impact of construction.

By using structural steel in construction projects, we can help to reduce our environmental impact and conserve natural resources. Structural steel is a sustainable choice that can help us to build a more sustainable future.

Frequently Asked Questions about Structural Steel Fabrication Denver

This FAQ section provides answers to common questions and misconceptions about structural steel fabrication in Denver.

Question 1: What is structural steel fabrication?

Structural steel fabrication is the process of creating steel structures by cutting, bending, and welding steel beams, plates, and other steel elements. These structures are used in a variety of applications, including buildings, bridges, and industrial facilities.

Question 2: What are the benefits of using structural steel?

Structural steel offers numerous benefits, including strength, durability, cost-effectiveness, and sustainability. Steel structures are strong and can withstand heavy loads, making them ideal for high-rise buildings and other large structures. Steel is also durable and can resist corrosion and fire, making it a long-lasting material.

Question 3: What is the process of structural steel fabrication?

Structural steel fabrication involves several key steps, including planning, materials procurement, cutting, bending, welding, inspection, erection, and maintenance. Careful planning and coordination are essential to ensure the successful fabrication of structural steel components.

Question 4: What are the different types of steel used in structural steel fabrication?

Various types of steel are used in structural steel fabrication, each with its own unique properties. Some common types include carbon steel, alloy steel, and stainless steel. The type of steel used depends on the specific requirements of the project, such as strength, durability, and corrosion resistance.

Question 5: What are the applications of structural steel fabrication?

Structural steel fabrication is used in a wide range of applications, including the construction of buildings, bridges, industrial facilities, and other structures. Steel structures are known for their strength, durability, and cost-effectiveness, making them a popular choice for various construction projects.

Question 6: How can I ensure the quality of structural steel fabrication?

Ensuring the quality of structural steel fabrication requires careful planning, material selection, skilled workmanship, and rigorous inspection. Adhering to industry standards and codes, working with reputable fabricators, and conducting thorough inspections throughout the fabrication process are crucial for delivering high-quality steel structures.

These are just a few of the most frequently asked questions about structural steel fabrication in Denver. By understanding the basics of structural steel fabrication, you can make informed decisions about the use of steel in your next project.

For more in-depth information on structural steel fabrication, please refer to the following resources:

- Wikipedia: Structural Steel Fabrication

- YouTube: Structural Steel Fabrication Denver

- Comparison of Structural Steel Fabrication Companies in Denver

Tips for Structural Steel Fabrication Denver

Structural steel fabrication is a critical component of the construction industry in Denver. By following these tips, you can ensure that your next structural steel fabrication project is a success.

Tip 1: Plan carefully.

The first step in any structural steel fabrication project is to plan carefully. This includes determining the scope of the project, the materials that will be used, and the timeline for completion. Careful planning will help you avoid delays and cost overruns.

Tip 2: Choose the right fabricator.

There are many structural steel fabricators in Denver to choose from. It is important to choose a fabricator that has a good reputation and that is experienced in the type of work that you need to be done. Ask for references and visit the fabricator’s shop before making a decision.

Tip 3: Use high-quality materials.

The quality of the materials that you use will have a big impact on the finished product. Be sure to use high-quality steel that meets the required specifications. Do not cut corners on materials, as this could compromise the safety and integrity of your structure.

Tip 4: Inspect the work regularly.

It is important to inspect the work of your structural steel fabricator regularly. This will help you to identify any problems early on and prevent them from becoming major issues. Inspections should be conducted by a qualified inspector.

Tip 5: Follow safety procedures.

Structural steel fabrication can be dangerous work. Be sure to follow all safety procedures and wear the appropriate safety gear. This will help to prevent accidents and injuries.

Tip 6: Get a warranty.

Most structural steel fabricators will offer a warranty on their work. This warranty will protect you in the event that there are any problems with the finished product. Be sure to get a warranty in writing before the work begins.

Tip 7: Maintain your structure.

Once your structural steel structure is complete, it is important to maintain it properly. This includes regular inspections, cleaning, and repairs. Proper maintenance will help to extend the life of your structure and prevent costly repairs down the road.

Tip 8: Hire a qualified engineer.

If you are not sure about any aspect of structural steel fabrication, be sure to hire a qualified engineer. An engineer can help you to design your structure, choose the right materials, and ensure that the work is done safely and correctly.

By following these tips, you can ensure that your next structural steel fabrication project is a success.

These tips will help you to:

- Avoid delays and cost overruns.

- Ensure the safety and integrity of your structure.

- Extend the life of your structure.

Conclusion

Structural steel fabrication is a critical component of the construction industry in Denver. By understanding the basics of structural steel fabrication, you can make informed decisions about the use of steel in your next project.Key points to remember: Structural steel is a strong, durable, and cost-effective material. Structural steel fabrication involves a variety of processes, including cutting, bending, welding, and inspection. It is important to choose a qualified structural steel fabricator and to use high-quality materials. Regular inspection and maintenance are essential to ensure the safety and longevity of your structural steel structure.The future of structural steel fabrication in Denver is bright. As the city continues to grow and develop, the demand for structural steel will only increase. By embracing innovation and new technologies, structural steel fabricators in Denver can continue to meet the needs of the construction industry and help to build a better future for the city.For more information on structural steel fabrication in Denver, please visit the following resources: [Wikipedia: Structural Steel Fabrication](/wikipedia) [YouTube: Structural Steel Fabrication Denver](/Youtube)* [Comparison of Structural Steel Fabrication Companies in Denver](/comparison)