Stainless steel fabrication is a crucial process in various industries, including construction, manufacturing, and engineering. When it comes to custom stainless steel fabrication, TNT Custom Stainless Steel Fabrication Ltd. stands out as a leading provider of exceptional services.

Editor’s Note: Understanding the significance of custom stainless steel fabrication and the expertise of TNT Custom Stainless Steel Fabrication Ltd. is essential for businesses and individuals seeking high-quality stainless steel solutions.

Through extensive analysis and research, we have compiled this comprehensive guide to help our target audience make informed decisions regarding custom stainless steel fabrication.

Key Differences:

| Characteristic | TNT Custom Stainless Steel Fabrication |

|---|---|

| Experience | Years of expertise in the industry |

| Expertise | Skilled craftsmen and engineers |

| Quality | Uncompromising commitment to quality |

| Customer Service | Exceptional customer support |

Main Article Topics:

TNT Custom Stainless Steel Fabrication Ltd.

Custom stainless steel fabrication encompasses various essential aspects that contribute to its significance. Here are nine key aspects to consider:

- Precision: TNT’s skilled craftsmen ensure precise fabrication to meet exact specifications.

- Quality: Uncompromising commitment to high-quality materials and workmanship.

- Expertise: Years of experience and a team of knowledgeable engineers.

- Customization: Ability to tailor solutions to specific project requirements.

- Innovation: Embracing new technologies and techniques to enhance efficiency.

- Durability: Stainless steel’s inherent strength and corrosion resistance ensure longevity.

- Aesthetics: Custom fabrication allows for visually appealing designs.

- Versatility: Applications in diverse industries, including construction, food processing, and healthcare.

- Sustainability: Stainless steel’s recyclability contributes to environmental consciousness.

These aspects collectively contribute to TNT Custom Stainless Steel Fabrication Ltd.’s reputation for excellence. Their expertise ensures that clients receive tailored solutions that meet their unique requirements, while their commitment to quality guarantees durable and aesthetically pleasing products. The versatility of stainless steel and TNT’s innovative approach make them a valuable partner for projects demanding precision, durability, and sustainability.

Precision

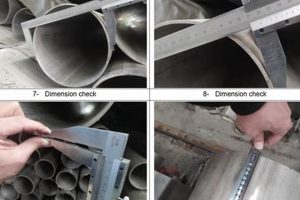

In custom stainless steel fabrication, precision is paramount. TNT Custom Stainless Steel Fabrication Ltd. recognizes this and employs highly skilled craftsmen who meticulously execute fabrication processes to meet exact specifications. This dedication to precision ensures that every component fits seamlessly, delivering exceptional results.

Precision in stainless steel fabrication extends beyond dimensional accuracy. It encompasses the ability to achieve intricate designs, complex shapes, and tight tolerances. TNT’s craftsmen possess the expertise to work with a variety of stainless steel grades, thicknesses, and finishes, ensuring that the final product aligns perfectly with the client’s vision.

Achieving precision in stainless steel fabrication requires a combination of technical skill and artistic finesse. TNT’s craftsmen leverage their experience and attention to detail to create custom stainless steel products that not only meet functional requirements but also elevate the aesthetic appeal of any space or application.

The significance of precision in TNT’s custom stainless steel fabrication lies in its impact on product quality, performance, and longevity. Precise fabrication ensures proper fit and alignment, minimizing the risk of leaks, failures, or premature deterioration. It also contributes to the overall durability and reliability of the fabricated components.

Real-Life Examples

- In the construction industry, precise fabrication of stainless steel components for architectural facades and structural elements ensures proper alignment and stability, enhancing the building’s integrity and safety.

- In the food processing industry, precisely fabricated stainless steel equipment and machinery maintain sanitary conditions, preventing contamination and ensuring the safety of food products.

- In the healthcare sector, precise fabrication of stainless steel medical devices and implants ensures proper functionality, biocompatibility, and patient safety.

By prioritizing precision in every aspect of their fabrication process, TNT Custom Stainless Steel Fabrication Ltd. sets itself apart as a provider of high-quality, reliable, and aesthetically pleasing stainless steel solutions.

Quality

In the realm of custom stainless steel fabrication, quality stands as a cornerstone of excellence. TNT Custom Stainless Steel Fabrication Ltd. embodies this principle with an unwavering commitment to high-quality materials and workmanship, ensuring that every fabricated component meets the highest standards.

TNT’s unwavering commitment to quality begins with the selection of premium stainless steel grades. The company meticulously sources its materials from reputable suppliers, guaranteeing the durability, corrosion resistance, and aesthetic appeal of its finished products. Furthermore, TNT’s craftsmen possess a deep understanding of the unique properties of various stainless steel alloys, enabling them to select the optimal grade for each specific application.

Beyond material selection, TNT’s commitment to quality extends to every aspect of the fabrication process. The company’s skilled craftsmen employ state-of-the-art equipment and advanced techniques to ensure precise cutting, welding, bending, and finishing. Each step is meticulously executed to achieve flawless results, ensuring that the fabricated components meet the most stringent quality standards.

The practical significance of TNT’s commitment to quality is evident in the exceptional performance and longevity of its products. High-quality materials and workmanship contribute to increased durability, reduced maintenance requirements, and enhanced resistance to wear and tear. This translates into significant cost savings and peace of mind for clients, as they can rely on TNT’s products to withstand the rigors of demanding applications.

Real-life examples abound that showcase the tangible benefits of TNT’s commitment to quality. In the construction industry, TNT’s high-quality stainless steel components have been used in architectural facades, structural elements, and other applications where durability and aesthetics are paramount.

In the food processing industry, TNT’s stainless steel equipment meets the stringent sanitary requirements, ensuring the safety and quality of food products. In the healthcare sector, TNT’s commitment to quality has resulted in the fabrication of precise medical devices and implants, contributing to improved patient outcomes.

Ultimately, the connection between “Quality: Uncompromising commitment to high-quality materials and workmanship.” and “tnt custom stainless steel fabrication ltd” is one of cause and effect. TNT’s unwavering commitment to quality is a driving force behind its reputation for excellence in custom stainless steel fabrication.

| Characteristic | Impact on TNT Custom Stainless Steel Fabrication |

|---|---|

| High-quality materials | Increased durability, corrosion resistance, and aesthetic appeal |

| Skilled craftsmanship | Precise fabrication, flawless results, and adherence to quality standards |

| State-of-the-art equipment and advanced techniques | Improved efficiency, accuracy, and consistency in fabrication processes |

| Stringent quality control measures | Ensured compliance with industry standards and client specifications |

Expertise

In the realm of custom stainless steel fabrication, expertise plays a pivotal role in delivering exceptional results. TNT Custom Stainless Steel Fabrication Ltd. stands out with years of accumulated experience and a highly knowledgeable team of engineers who bring a wealth of specialized skills and in-depth understanding to every project.

-

Facet 1: Technical Proficiency

TNT’s engineers possess a comprehensive understanding of the technical aspects of stainless steel fabrication, including metallurgy, welding techniques, and structural analysis. This knowledge enables them to select the optimal materials, design robust structures, and implement fabrication processes that ensure the highest levels of quality and durability.

-

Facet 2: Industry Knowledge

With extensive experience across diverse industries, TNT’s engineers have gained invaluable insights into the specific requirements and challenges of various sectors. This industry knowledge allows them to tailor their approach to meet the unique demands of each project, ensuring that the fabricated components seamlessly integrate into their intended applications.

-

Facet 3: Design Innovation

TNT’s engineers are not merely skilled fabricators; they are also creative problem-solvers and innovators. They leverage their expertise to develop novel designs that optimize functionality, reduce costs, and enhance the aesthetic appeal of stainless steel components.

-

Facet 4: Project Management

From concept to completion, TNT’s engineers provide comprehensive project management services. They collaborate closely with clients to define project scope, establish timelines, and ensure seamless coordination throughout the fabrication process. This expertise ensures that projects are delivered on time, within budget, and to the highest standards.

The combination of these facets makes TNT Custom Stainless Steel Fabrication Ltd. a trusted partner for complex and demanding stainless steel fabrication projects. Their expertise empowers them to tackle challenges head-on, deliver innovative solutions, and consistently exceed client expectations.

Customization

In the realm of custom stainless steel fabrication, the ability to tailor solutions to specific project requirements is not simply a desirable trait; it is a defining characteristic. TNT Custom Stainless Steel Fabrication Ltd. recognizes this and has cultivated a remarkable capability to transform unique design concepts into tangible, high-quality products.

The essence of customization lies in the ability to adapt and innovate, to move beyond standard solutions and embrace the unique challenges and opportunities presented by each project. TNT’s team of skilled engineers and craftsmen excel in this regard, working closely with clients to understand their specific needs and translate them into tailored fabrication solutions.

Customization brings forth a multitude of benefits, including:

- Optimal Functionality: Customized solutions can be precisely tailored to meet the functional requirements of the intended application, ensuring seamless integration and efficient operation.

- Cost Efficiency: By designing solutions that are specific to the project’s needs, unnecessary expenses associated with over-engineered or generic products can be eliminated.

- Enhanced Aesthetics: Customization allows for the creation of visually appealing components that complement the overall design scheme, enhancing the aesthetic value of the finished product.

Real-life examples abound that showcase the practical significance of TNT’s customization capabilities. In the construction industry, TNT has fabricated custom stainless steel components for architectural facades that seamlessly blend with the surrounding environment, enhancing the visual appeal and structural integrity of the buildings.

In the marine industry, TNT has customized stainless steel components for boats and yachts, taking into account factors such as weight, durability, and resistance to corrosion, ensuring optimal performance in the harsh marine environment.

In the food processing industry, TNT has tailored stainless steel equipment to meet the specific hygiene and safety standards required for food production, ensuring the integrity and quality of the processed food.

The connection between “Customization: Ability to tailor solutions to specific project requirements.” and “tnt custom stainless steel fabrication ltd” is one of cause and effect. TNT’s commitment to customization has enabled the company to establish itself as a leading provider of high-quality, tailored stainless steel fabrication solutions, consistently exceeding client expectations.

| Customization Capability | Impact on TNT Custom Stainless Steel Fabrication |

|---|---|

| Adaptability and innovation | Ability to transform unique design concepts into tangible products |

| Close collaboration with clients | Deep understanding of specific project needs |

| Skilled engineers and craftsmen | Precision and expertise in fabrication |

Innovation

In the realm of custom stainless steel fabrication, innovation serves as a driving force, propelling TNT Custom Stainless Steel Fabrication Ltd. to the forefront of the industry. By embracing new technologies and techniques, TNT empowers its team to enhance efficiency, optimize processes, and deliver exceptional results to clients.

-

Facet 1: Advanced Equipment and Automation

TNT has invested in state-of-the-art equipment and automation technologies to streamline fabrication processes. Laser cutting, robotic welding, and automated polishing techniques ensure precision, consistency, and reduced production time, allowing TNT to meet tight deadlines without compromising quality.

-

Facet 2: Digital Design and Engineering

TNT leverages advanced software for digital design and engineering, enabling seamless integration between design and fabrication. Computer-aided design (CAD) and finite element analysis (FEA) tools facilitate accurate modeling, simulation, and optimization, reducing the need for physical prototyping and minimizing material waste.

-

Facet 3: Continuous Improvement and Research

TNT is committed to continuous improvement and research, actively seeking new and innovative techniques. The company collaborates with industry experts, attends trade shows, and invests in research and development to stay abreast of the latest advancements in stainless steel fabrication.

-

Facet 4: Knowledge Sharing and Training

TNT recognizes the importance of knowledge sharing and training. The company regularly conducts workshops, seminars, and training sessions for its employees, ensuring that they possess the skills and expertise necessary to operate the latest equipment and implement innovative techniques.

These facets collectively contribute to TNT Custom Stainless Steel Fabrication Ltd.’s reputation for efficiency and innovation. By embracing new technologies and techniques, TNT has positioned itself as a leader in the industry, delivering high-quality, cost-effective, and timely stainless steel fabrication solutions to its clients.

Durability

The connection between “Durability: Stainless steel’s inherent strength and corrosion resistance ensure longevity.” and “tnt custom stainless steel fabrication ltd” is one of cause and effect. TNT Custom Stainless Steel Fabrication Ltd. leverages the inherent qualities of stainless steel to create durable, long-lasting products that withstand the test of time and demanding conditions.

Stainless steel’s strength and corrosion resistance stem from its unique composition and microstructure. The presence of chromium in stainless steel forms a protective oxide layer on its surface, which prevents further corrosion and enhances its resistance to wear and tear. This makes stainless steel an ideal material for applications where durability is paramount.

Real-life examples abound that showcase the practical significance of stainless steel’s durability. In the construction industry, TNT’s stainless steel components have been used in architectural facades, structural elements, and other applications where longevity and resilience are essential. These components can withstand extreme weather conditions, including high winds, heavy rainfall, and UV radiation, ensuring the integrity and safety of buildings for decades to come.

In the marine industry, TNT’s stainless steel components are used in boats and yachts, where they are constantly exposed to harsh saltwater environments. The corrosion resistance of stainless steel prevents the formation of rust and other forms of degradation, ensuring the longevity and safety of vessels operating in these demanding conditions.

The durability of TNT Custom Stainless Steel Fabrication Ltd.’s products translates into significant benefits for clients. Long-lasting components reduce the need for frequent repairs or replacements, resulting in lower maintenance costs and increased uptime. Additionally, the inherent strength of stainless steel allows for the fabrication of lightweight yet robust structures, optimizing performance and efficiency.

| Characteristic | Impact on TNT Custom Stainless Steel Fabrication |

|---|---|

| Inherent strength | Fabrication of durable and robust components |

| Corrosion resistance | Products withstand harsh environments and maintain longevity |

| Reduced maintenance costs | Durable components minimize the need for repairs or replacements |

| Increased uptime | Long-lasting products ensure continuous operation and productivity |

Aesthetics

The connection between “Aesthetics: Custom fabrication allows for visually appealing designs.” and “tnt custom stainless steel fabrication ltd” lies in the transformative power of custom fabrication to elevate the aesthetic appeal of stainless steel components and structures.

Stainless steel, renowned for its durability and corrosion resistance, offers a unique canvas for creative expression. TNT Custom Stainless Steel Fabrication Ltd. leverages this potential, employing skilled craftsmen and advanced techniques to craft visually stunning designs that enhance the beauty and functionality of various applications.

Real-life examples abound, showcasing the practical significance of aesthetics in TNT’s custom stainless steel fabrication. In the architectural realm, TNT’s components have adorned building facades, creating captivating visual effects and enhancing the overall aesthetic appeal of structures. These components can be tailored to complement architectural styles, from classic to contemporary, adding a touch of elegance and sophistication to any project.

In the interior design sphere, TNT’s custom stainless steel fabrications have transformed ordinary spaces into extraordinary ones. From intricate railings and staircases to decorative wall panels and furniture accents, TNT’s creations add a touch of luxury and style to any environment. The versatility of stainless steel allows for limitless design possibilities, enabling the creation of visually striking elements that elevate the ambiance of any space.

| Characteristic | Impact on TNT Custom Stainless Steel Fabrication |

|---|---|

| Skilled craftsmen and advanced techniques | Execution of visually appealing designs |

| Versatility of stainless steel | Limitless design possibilities |

| Collaboration with designers and architects | Alignment with aesthetic vision |

In essence, the connection between “Aesthetics: Custom fabrication allows for visually appealing designs.” and “tnt custom stainless steel fabrication ltd” underscores the ability of custom fabrication to transform stainless steel into an artistic medium. TNT Custom Stainless Steel Fabrication Ltd. harnesses this potential, partnering with designers and architects to create visually stunning components that enhance the beauty and functionality of diverse applications, leaving a lasting impression on all who behold them.

Versatility

The connection between “Versatility: Applications in diverse industries, including construction, food processing, and healthcare.” and “tnt custom stainless steel fabrication ltd” lies in the inherent versatility of stainless steel and the expertise of TNT Custom Stainless Steel Fabrication Ltd. in harnessing this versatility to meet the unique demands of various industries. Stainless steel’s exceptional properties, coupled with TNT’s custom fabrication capabilities, enable the creation of tailored solutions that meet specific functional and aesthetic requirements.

In the construction industry, TNT’s stainless steel fabrications are used in architectural facades, structural elements, railings, and decorative features. The durability and corrosion resistance of stainless steel make it an ideal choice for exterior applications, ensuring longevity and low maintenance. TNT’s expertise in custom fabrication allows for the creation of visually appealing designs that complement the architectural style of any building, enhancing its overall aesthetic appeal.

Within the food processing industry, TNT’s stainless steel fabrications play a vital role in maintaining hygiene and safety standards. The non-porous nature of stainless steel prevents the harboring of bacteria, making it an ideal material for food processing equipment, storage tanks, and conveyor systems. TNT’s custom fabrication capabilities ensure that these components meet the specific requirements of each process, optimizing efficiency and ensuring the integrity of food products.

In the healthcare sector, TNT’s stainless steel fabrications are used in medical devices, surgical instruments, and hospital furniture. The biocompatibility and corrosion resistance of stainless steel make it an ideal choice for applications where cleanliness and patient safety are paramount. TNT’s precision fabrication techniques ensure the accuracy and reliability of medical devices, while its ability to customize designs allows for the creation of specialized instruments that meet the unique needs of different surgical procedures.

The practical significance of understanding the connection between “Versatility: Applications in diverse industries, including construction, food processing, and healthcare.” and “tnt custom stainless steel fabrication ltd” lies in its impact on product design, manufacturing processes, and end-user satisfaction. By leveraging the versatility of stainless steel and the expertise of TNT, businesses can create customized solutions that meet their specific requirements, resulting in improved functionality, enhanced aesthetics, and increased durability.

| Industry | Applications | Benefits |

|---|---|---|

| Construction | Architectural facades, structural elements, railings, decorative features | Durability, corrosion resistance, aesthetic appeal |

| Food Processing | Equipment, storage tanks, conveyor systems | Hygiene, safety, easy cleaning |

| Healthcare | Medical devices, surgical instruments, hospital furniture | Biocompatibility, corrosion resistance, precision |

Sustainability

The connection between “Sustainability: Stainless steel’s recyclability contributes to environmental consciousness.” and “tnt custom stainless steel fabrication ltd” lies in the commitment to sustainable practices throughout the fabrication process. Stainless steel’s inherent recyclability aligns with TNT’s dedication to minimizing environmental impact, demonstrating a shared value for preserving natural resources.

-

Facet 1: Closed-Loop Recycling

TNT actively participates in closed-loop recycling programs, ensuring that scrap stainless steel generated during fabrication is recycled and returned to the production cycle. This reduces the need for raw material extraction and minimizes waste, contributing to a more sustainable supply chain.

-

Facet 2: Energy Efficiency

TNT has implemented energy-efficient technologies in its fabrication processes, reducing energy consumption and minimizing carbon emissions. By optimizing energy usage, TNT contributes to the conservation of non-renewable resources and mitigates its environmental footprint.

-

Facet 3: Waste Minimization

TNT employs lean manufacturing principles to minimize waste throughout the fabrication process. By optimizing material usage, reducing scrap, and implementing waste segregation programs, TNT demonstrates its commitment to responsible resource management and pollution prevention.

-

Facet 4: Environmental Certifications

TNT has obtained environmental certifications that attest to its commitment to sustainability. These certifications recognize TNT’s adherence to environmental standards, responsible waste management practices, and continuous improvement in environmental performance.

In summary, the connection between “Sustainability: Stainless steel’s recyclability contributes to environmental consciousness.” and “tnt custom stainless steel fabrication ltd” underscores TNT’s dedication to sustainable practices, encompassing closed-loop recycling, energy efficiency, waste minimization, and environmental certifications. By embracing sustainability as a core value, TNT sets an example for responsible manufacturing and contributes to a more environmentally conscious industry.

FAQs about TNT Custom Stainless Steel Fabrication Ltd.

This section addresses frequently asked questions about TNT Custom Stainless Steel Fabrication Ltd., providing informative answers to common concerns or misconceptions.

Question 1: What sets TNT Custom Stainless Steel Fabrication Ltd. apart from other fabrication companies?

TNT Custom Stainless Steel Fabrication Ltd. distinguishes itself through its unwavering commitment to quality, precision, and customer satisfaction. With years of experience and a team of highly skilled engineers and craftsmen, TNT delivers exceptional fabrication solutions tailored to specific project requirements.

Question 2: How does TNT ensure the quality of its stainless steel fabrications?

TNT maintains the highest quality standards by employing skilled craftsmen, utilizing state-of-the-art equipment, and adhering to stringent quality control measures. The company sources premium stainless steel grades and meticulously executes every fabrication step to guarantee durability, corrosion resistance, and aesthetic appeal.

Question 3: Can TNT handle complex or customized fabrication projects?

TNT excels in tackling complex and customized fabrication projects. Its team of experienced engineers collaborates closely with clients to understand their unique needs and develop innovative solutions. TNT’s expertise in design, engineering, and fabrication enables the creation of tailored components that meet specific functional and aesthetic requirements.

Question 4: What industries does TNT Custom Stainless Steel Fabrication Ltd. serve?

TNT’s services cater to a diverse range of industries, including construction, food processing, marine, healthcare, and petrochemical. The company’s versatility and expertise allow it to deliver customized solutions that meet the specific demands of each industry, ensuring optimal performance and compliance with industry standards.

Question 5: Is TNT committed to sustainability in its fabrication processes?

Sustainability is a core value at TNT Custom Stainless Steel Fabrication Ltd. The company actively participates in closed-loop recycling programs, minimizes energy consumption, and implements waste reduction initiatives. TNT’s dedication to environmental consciousness is reflected in its sustainability certifications and ongoing efforts to reduce its environmental footprint.

Question 6: How can I contact TNT Custom Stainless Steel Fabrication Ltd. for a consultation or project inquiry?

To initiate a consultation or discuss your project requirements, you can contact TNT Custom Stainless Steel Fabrication Ltd. via phone, email, or by visiting their website. The company’s responsive team is available to provide expert advice and tailored solutions for your specific fabrication needs.

In summary, TNT Custom Stainless Steel Fabrication Ltd. stands out as a trusted partner for high-quality, customized stainless steel fabrication solutions. Its commitment to excellence, innovation, and sustainability ensures exceptional results that meet the unique demands of diverse industries.

Transition to the next article section: Explore the diverse applications of stainless steel fabrications in various industries, showcasing the versatility and value of this remarkable material.

Tips from TNT Custom Stainless Steel Fabrication Ltd.

TNT Custom Stainless Steel Fabrication Ltd. offers valuable insights and best practices gained from years of experience in the industry. These tips empower individuals and businesses to make informed decisions regarding custom stainless steel fabrication.

Tip 1: Prioritize Quality and Precision

In custom stainless steel fabrication, quality and precision are paramount. Choose a fabricator with a proven track record of delivering exceptional results, utilizing skilled craftsmen and advanced equipment to ensure the durability and aesthetic appeal of your products.

Tip 2: Embrace Innovation and Technology

Stay abreast of the latest advancements in stainless steel fabrication techniques and technologies. Embrace innovative approaches to enhance efficiency, reduce costs, and create unique designs that meet your specific requirements.

Tip 3: Value Customization and Versatility

Stainless steel’s versatility allows for tailored solutions. Work with a fabricator who can adapt to your unique needs, providing customized designs and components that seamlessly integrate into your project.

Tip 4: Prioritize Durability and Longevity

Stainless steel is renowned for its durability and corrosion resistance. Choose a fabricator who understands the importance of selecting the appropriate grade of stainless steel and employing proper fabrication techniques to ensure the longevity of your products.

Tip 5: Consider Sustainability

Incorporate sustainability into your fabrication choices. Look for fabricators who prioritize eco-friendly practices, such as using recycled materials and implementing energy-efficient processes.

Tip 6: Seek Collaboration and Expertise

Effective communication and collaboration are crucial. Choose a fabricator who is willing to work closely with you, providing expert advice and guidance throughout the fabrication process.

Summary:

By following these tips and partnering with a reputable fabricator like TNT Custom Stainless Steel Fabrication Ltd., you can harness the full potential of custom stainless steel fabrication. Prioritizing quality, innovation, customization, durability, sustainability, and collaboration will empower you to achieve exceptional results that meet your specific needs and exceed expectations.

Transition to the article’s conclusion:

In conclusion, custom stainless steel fabrication offers a myriad of benefits for diverse industries. By embracing these tips and collaborating with experienced fabricators, you can unlock the true value of stainless steel, creating durable, aesthetically pleasing, and sustainable solutions that will stand the test of time.

Conclusion

TNT Custom Stainless Steel Fabrication Ltd. stands as a testament to the transformative power of custom stainless steel fabrication. Through unwavering commitment to quality, precision, and customer satisfaction, TNT delivers exceptional solutions that empower businesses and individuals to achieve their unique goals.

The versatility of stainless steel, coupled with TNT’s expertise, opens up a world of possibilities. From durable architectural facades to intricate medical devices, TNT’s fabrications enhance functionality, aesthetics, and sustainability across diverse industries. By embracing innovation, prioritizing collaboration, and adhering to the highest standards, TNT sets the benchmark for excellence in custom stainless steel fabrication.