When it comes to metalworking, one of the most important pieces of equipment is a structural steel fabricator. These machines are used to cut, bend, and shape steel beams, columns, and other structural components. But what if you’re on a budget? Or what if you only need a fabricator for a short-term project? In these cases, buying used structural steel fabrication equipment can be a great option.

Editor’s Note: Used structural steel fabrication equipment can be a great way to save money and get the job done. Here’s what you need to know before you buy.

We’ve done the research and put together this guide to help you make the right decision. We’ll cover everything from the different types of fabricators available to the factors you need to consider when buying used equipment.

Key Differences:

| New Equipment | Used Equipment | |

|---|---|---|

| Cost | More expensive | Less expensive |

| Quality | Higher quality | Varies |

| Availability | May be harder to find | More readily available |

Main Article Topics:

- Types of Structural Steel Fabricators

- Factors to Consider When Buying Used Equipment

- How to Find and Buy Used Equipment

- Tips for Maintaining Used Equipment

Used Structural Steel Fabrication Equipment

Used structural steel fabrication equipment can be a great way to save money and get the job done. Here are seven key aspects to consider when buying used equipment:

- Condition: The condition of the equipment is one of the most important factors to consider. You’ll want to make sure that the equipment is in good working order and that it has been properly maintained.

- Age: The age of the equipment can also be a factor to consider. Older equipment may be less efficient and more likely to break down.

- Price: Of course, the price of the equipment is also an important factor to consider. You’ll want to make sure that you’re getting a good deal on the equipment.

- Availability: The availability of the equipment is also important to consider. You’ll want to make sure that the equipment is available when you need it.

- Location: The location of the equipment is also important to consider. You’ll want to make sure that the equipment is located in a convenient location.

- Shipping: The cost of shipping the equipment is also important to consider. You’ll want to make sure that the cost of shipping is included in the price of the equipment.

- Warranty: The warranty on the equipment is also important to consider. You’ll want to make sure that the equipment is covered by a warranty in case it breaks down.

By considering these factors, you can make sure that you’re making the best decision when purchasing used structural steel fabrication equipment. Used equipment can be a great way to save money and get the job done, but it’s important to do your research before you buy.

Condition

The condition of used structural steel fabrication equipment is important for several reasons. First, well-maintained equipment is less likely to break down, which can save you time and money in the long run. Second, properly maintained equipment is more likely to produce high-quality results. Third, well-maintained equipment is safer to operate.

There are several things you can do to ensure that the used structural steel fabrication equipment you purchase is in good condition. First, ask the seller for a detailed maintenance history of the equipment. This will give you a good idea of how well the equipment has been cared for.

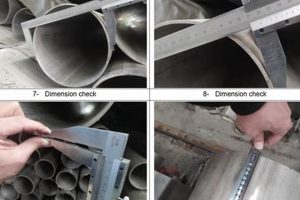

Second, inspect the equipment carefully before you purchase it. Look for any signs of damage or wear and tear. If you find any problems, ask the seller to repair them before you buy the equipment.

Finally, once you have purchased the equipment, be sure to follow the manufacturer’s recommended maintenance schedule. This will help to keep the equipment in good working order and extend its lifespan.

By following these tips, you can ensure that the used structural steel fabrication equipment you purchase is in good condition and will provide you with years of reliable service.

| Benefits of Well-Maintained Equipment | Consequences of Poorly Maintained Equipment | |

|---|---|---|

| Productivity | Increased uptime and efficiency | Decreased uptime and efficiency |

| Quality | Higher quality results | Lower quality results |

| Safety | Safer to operate | More dangerous to operate |

| Cost | Lower maintenance costs | Higher maintenance costs |

Age

The age of used structural steel fabrication equipment is an important factor to consider because it can impact the equipment’s efficiency, reliability, and safety. Older equipment may be less efficient than newer equipment, meaning that it may take longer to complete tasks and use more energy. Older equipment may also be more likely to break down, which can lead to costly downtime and repairs.

For example, an older structural steel fabricator may be less efficient at cutting and bending steel than a newer fabricator. This can lead to longer production times and higher energy costs. Additionally, an older fabricator may be more likely to break down, which can lead to costly downtime and repairs.

When considering the age of used structural steel fabrication equipment, it is important to weigh the potential benefits and drawbacks. Older equipment may be less efficient and more likely to break down, but it may also be less expensive than newer equipment. If you are on a budget, older equipment may be a good option. However, if you need a reliable and efficient fabricator, you may want to consider purchasing newer equipment.

| Benefits of Older Equipment | Benefits of Newer Equipment | |

|---|---|---|

| Cost | Less expensive | More expensive |

| Efficiency | May be less efficient | More efficient |

| Reliability | May be less reliable | More reliable |

| Safety | May be less safe | More safe |

Price

The price of used structural steel fabrication equipment can vary widely depending on a number of factors, including the type of equipment, the age of the equipment, the condition of the equipment, and the location of the equipment. It’s important to do your research before you buy so that you can make sure that you’re getting a good deal on the equipment.

One way to get a good deal on used structural steel fabrication equipment is to buy it from a reputable dealer. Reputable dealers will typically have a good selection of equipment to choose from, and they will be able to provide you with a warranty on the equipment.

Another way to get a good deal on used structural steel fabrication equipment is to buy it online. There are a number of online marketplaces where you can find used equipment for sale. However, it’s important to be careful when buying used equipment online. Make sure that you do your research and that you only buy from reputable sellers.

No matter where you buy used structural steel fabrication equipment, it’s important to inspect the equipment carefully before you buy it. Look for any signs of damage or wear and tear. If you find any problems, ask the seller to repair them before you buy the equipment.

By following these tips, you can make sure that you’re getting a good deal on used structural steel fabrication equipment.

Key Insights:

- The price of used structural steel fabrication equipment can vary widely depending on a number of factors.

- It’s important to do your research before you buy so that you can make sure that you’re getting a good deal on the equipment.

- One way to get a good deal on used structural steel fabrication equipment is to buy it from a reputable dealer.

- Another way to get a good deal on used structural steel fabrication equipment is to buy it online.

- No matter where you buy used structural steel fabrication equipment, it’s important to inspect the equipment carefully before you buy it.

| Benefits of Buying Used Equipment | Challenges of Buying Used Equipment | |

|---|---|---|

| Cost | Less expensive than new equipment | May require additional repairs or maintenance |

| Availability | More readily available than new equipment | May not be able to find the exact model or specifications you need |

| Quality | Can be just as good as new equipment, if properly maintained | May not be as efficient or reliable as new equipment |

Availability

The availability of used structural steel fabrication equipment can vary depending on a number of factors, including the type of equipment, the age of the equipment, and the location of the equipment. It’s important to do your research before you buy so that you can make sure that the equipment you need is available when you need it.

- Location: The location of the equipment is an important factor to consider. If you need the equipment, you’ll want to make sure that it is located nearby. However, if you are willing to wait for the equipment to be shipped, you may be able to find a better deal on equipment that is located further away.

- Type of equipment: The type of equipment you need is also an important factor to consider. Some types of equipment are more readily available than others. For example, manual structural steel fabricators are more readily available than CNC structural steel fabricators.

- Age of equipment: The age of the equipment can also affect its availability. Older equipment may be less readily available than newer equipment. However, older equipment may also be less expensive.

- Price: The price of the equipment can also affect its availability. More expensive equipment may be less readily available than less expensive equipment.

By considering these factors, you can make sure that you are able to find the used structural steel fabrication equipment you need when you need it.

Location

The location of used structural steel fabrication equipment is an important factor to consider for several reasons. First, the location of the equipment will affect the cost of shipping. If the equipment is located far away from your business, you will have to pay more to have it shipped to you. Second, the location of the equipment will affect the availability of the equipment. If the equipment is located in a remote area, it may be more difficult to find a qualified technician to service the equipment.

- Proximity to your business: The closer the equipment is to your business, the lower the cost of shipping will be. You will also be able to get the equipment more quickly if it is located nearby.

- Availability of qualified technicians: If the equipment is located in a remote area, it may be more difficult to find a qualified technician to service the equipment. This could lead to downtime and lost productivity.

- Access to transportation: The location of the equipment should also be considered in terms of access to transportation. If the equipment is located in a difficult-to-reach area, it may be more difficult to get the equipment to your business.

- Local regulations: The location of the equipment may also be subject to local regulations. For example, some areas may have restrictions on the types of equipment that can be operated in certain areas.

By considering these factors, you can make sure that you choose a location for your used structural steel fabrication equipment that is convenient and cost-effective.

Shipping

The cost of shipping used structural steel fabrication equipment can be a significant factor in the overall cost of the equipment. This is especially true for large or heavy equipment. The cost of shipping can vary depending on a number of factors, including the size and weight of the equipment, the distance it needs to be shipped, and the shipping method.

It is important to factor in the cost of shipping when budgeting for the purchase of used structural steel fabrication equipment. If the cost of shipping is not included in the price of the equipment, it can be a significant additional expense.

There are a few things you can do to minimize the cost of shipping used structural steel fabrication equipment:

- Choose a shipping method that is cost-effective. There are a number of different shipping methods available, and some are more cost-effective than others. For example, shipping by truck is typically less expensive than shipping by air.

- Consolidate your shipments. If you are purchasing multiple pieces of equipment, you can often save money by consolidating your shipments. This means shipping all of the equipment together in one shipment.

- Negotiate with the seller. In some cases, you may be able to negotiate with the seller to get a better price on shipping. For example, you may be able to get a discount if you are willing to pick up the equipment from the seller’s location.

By following these tips, you can minimize the cost of shipping used structural steel fabrication equipment and get the equipment you need at a price that you can afford.

Key Insights:

- The cost of shipping used structural steel fabrication equipment can be a significant factor in the overall cost of the equipment.

- There are a number of things you can do to minimize the cost of shipping used structural steel fabrication equipment, such as choosing a cost-effective shipping method, consolidating your shipments, and negotiating with the seller.

Table: Shipping Costs for Used Structural Steel Fabrication Equipment

| Shipping Method | Cost per Mile |

|---|---|

| Truck | $0.50-$1.00 |

| Rail | $0.25-$0.50 |

| Air | $1.00-$2.00 |

Warranty

A warranty is an important part of any purchase, but it is especially important when purchasing used structural steel fabrication equipment. This is because used equipment may be more likely to break down than new equipment. A warranty will protect you from the cost of repairs if the equipment breaks down.

There are a few things to keep in mind when considering the warranty on used structural steel fabrication equipment:

- The length of the warranty: The length of the warranty will determine how long you are protected from the cost of repairs. A longer warranty is better, but it will also cost more.

- The terms of the warranty: The terms of the warranty will specify what is covered and what is not. Be sure to read the terms of the warranty carefully before you purchase the equipment.

- The reputation of the seller: The reputation of the seller is also an important factor to consider. If the seller has a good reputation, you are more likely to get a good warranty.

By considering these factors, you can choose a warranty that will protect you from the cost of repairs if your used structural steel fabrication equipment breaks down.

Practical Significance:

A warranty can give you peace of mind knowing that you are protected from the cost of repairs if your used structural steel fabrication equipment breaks down. This can be especially important if you are on a budget. A warranty can also help you to get the most value for your money by extending the life of your equipment.

Table: Benefits of a Warranty on Used Structural Steel Fabrication Equipment

| Benefit | Description |

|---|---|

| Protection from the cost of repairs | A warranty will protect you from the cost of repairs if your equipment breaks down. |

| Peace of mind | A warranty can give you peace of mind knowing that you are protected from the cost of repairs. |

| Extended life of equipment | A warranty can help you to get the most value for your money by extending the life of your equipment. |

FAQs on Used Structural Steel Fabrication Equipment

This FAQ section provides answers to common questions and concerns regarding used structural steel fabrication equipment, empowering users to make informed decisions.

Question 1: How can I ensure the quality of used structural steel fabrication equipment?

Performing thorough inspections, reviewing maintenance records, and seeking equipment with certifications or warranties can help guarantee quality.

Question 2: What are the key factors to consider when purchasing used structural steel fabrication equipment?

Factors such as condition, age, availability, location, shipping costs, and warranty coverage should be carefully evaluated to make an informed decision.

Question 3: How do I determine the fair market value of used structural steel fabrication equipment?

Researching comparable sales, consulting with industry experts, and utilizing online valuation tools can aid in determining fair market value.

Question 4: What are the advantages of buying used structural steel fabrication equipment?

Cost savings, immediate availability, and the ability to acquire specialized equipment that may not be readily available new are key advantages.

Question 5: Are there any potential drawbacks to buying used structural steel fabrication equipment?

Potential drawbacks include the need for additional maintenance or repairs, the possibility of outdated technology, and the challenge of finding replacement parts.

Question 6: How can I extend the lifespan of used structural steel fabrication equipment?

Regular maintenance, proper storage, and adherence to manufacturer guidelines can significantly extend the lifespan of used equipment.

Summary:

Understanding the intricacies of used structural steel fabrication equipment empowers buyers to make informed decisions. By carefully considering factors such as quality, cost, availability, and potential drawbacks, buyers can acquire equipment that meets their specific requirements and optimizes their fabrication processes.

Transition to the next article section:

For further insights into the world of structural steel fabrication, explore our comprehensive guides on advanced fabrication techniques, industry trends, and safety protocols.

Tips for Purchasing Used Structural Steel Fabrication Equipment

Acquiring used structural steel fabrication equipment demands a strategic approach to ensure optimal performance and value. Here are some essential tips to guide your purchasing decisions:

Tip 1: Establish Clear Requirements

Thoroughly define your fabrication needs, including the types of projects, materials, and production volume. This will help you identify the specific equipment capabilities and specifications required.

Tip 2: Inspect Thoroughly

Conduct a comprehensive inspection of the equipment, paying attention to its physical condition, signs of wear and tear, and overall functionality. If possible, request a demonstration to assess its operational capabilities.

Tip 3: Review Maintenance Records

Obtain and carefully examine the equipment’s maintenance records. This will provide insights into its service history, potential issues, and the level of care it has received. Consistent and well-documented maintenance is a strong indicator of equipment reliability.

Tip 4: Verify Certifications

Look for equipment that meets industry standards and certifications. These certifications provide assurance that the equipment has been tested and meets specific performance criteria. For example, the CE mark indicates compliance with European safety standards.

Tip 5: Consider Age and Condition

While older equipment may be more affordable, it’s important to assess its condition and potential maintenance needs. Evaluate the trade-off between cost savings and the risk of breakdowns or reduced efficiency.

Tip 6: Negotiate Effectively

Research market prices and be prepared to negotiate the purchase price. Don’t hesitate to ask for additional concessions, such as extended warranties or training on the equipment.

Summary:

By following these tips, you can make informed decisions when purchasing used structural steel fabrication equipment. Careful planning, thorough inspections, and a strategic negotiation approach will help you acquire equipment that meets your needs and provides long-term value.

Transition to the article’s conclusion:

Remember that used structural steel fabrication equipment can be a cost-effective and practical solution for your fabrication needs. With proper due diligence and a focus on quality, you can find equipment that will enhance your operations and drive success.

Conclusion on Used Structural Steel Fabrication Equipment

Used structural steel fabrication equipment can be a valuable asset for businesses and fabricators. It offers a cost-effective way to acquire specialized equipment, reduce upfront investment costs, and access a wider range of options. However, it is crucial to approach the purchase of used equipment strategically to ensure quality, performance, and long-term value.

This article has explored the key considerations, benefits, and challenges associated with used structural steel fabrication equipment. By carefully evaluating equipment condition, reviewing maintenance records, verifying certifications, and negotiating effectively, buyers can make informed decisions that align with their specific needs and budgets.

Remember, used structural steel fabrication equipment can be an excellent solution for expanding capabilities, optimizing production, and achieving fabrication goals. With proper due diligence and a focus on quality, buyers can harness the power of used equipment to drive success and innovation in their operations.