What is a welding and fabrication resume?

Editor’s Notes: A welding and fabrication resume is a specialized type of resume tailored to highlight the skills and experience of professionals in the welding and fabrication industry.

After analyzing numerous welding and fabrication resumes and consulting with industry experts, we have compiled this comprehensive guide to help you create a resume that will showcase your skills and experience and land you the job you want.

Key Differences:

| Welding Resume | Fabrication Resume | |

|---|---|---|

| Focus | Welding skills and experience | Fabrication skills and experience |

| Sections | Welding experience, skills, certifications | Fabrication experience, skills, materials worked with |

| Keywords | Welding processes, welding equipment, welding materials | Fabrication processes, fabrication equipment, fabrication materials |

Main Article Topics:

- What is a Welding and Fabrication Resume?

- How to Write a Welding and Fabrication Resume

- Welding Resume vs. Fabrication Resume

Welding and Fabrication Resume

A welding and fabrication resume is a specialized type of resume tailored to highlight the skills and experience of professionals in the welding and fabrication industry. Key aspects to consider when writing a welding and fabrication resume include:

- Skills: Welding processes, fabrication processes, welding equipment, fabrication equipment

- Experience: Welding experience, fabrication experience, welding projects, fabrication projects

- Certifications: Welding certifications, fabrication certifications

- Education: Welding education, fabrication education

- Materials: Welding materials, fabrication materials

- Industries: Welding industries, fabrication industries

- Keywords: Welding keywords, fabrication keywords

By focusing on these key aspects, you can create a welding and fabrication resume that will showcase your skills and experience and land you the job you want. For example, if you are a welder with experience in welding pipe, you should highlight your skills in pipe welding and list any relevant projects you have worked on. If you are a fabricator with experience in working with stainless steel, you should highlight your skills in stainless steel fabrication and list any relevant projects you have worked on.

Skills

The skills section of a welding and fabrication resume is one of the most important sections, as it highlights the welder or fabricator’s abilities and experience. When listing skills, it is important to be specific and to use keywords that potential employers will be looking for. Some of the most important skills to include in a welding and fabrication resume include:

- Welding processes: MIG welding, TIG welding, stick welding, flux-cored arc welding, plasma arc welding, laser welding

- Fabrication processes: Cutting, bending, forming, rolling, welding, assembling, finishing

- Welding equipment: Welding machines, welding guns, welding torches, welding rods, welding wire

- Fabrication equipment: Cutting machines, bending machines, forming machines, rolling machines, welding machines, assembly tools, finishing tools

By including these skills in your welding and fabrication resume, you will be able to showcase your abilities and experience to potential employers and increase your chances of landing the job you want.

For example, if you are a welder with experience in welding pipe, you should highlight your skills in pipe welding and list any relevant projects you have worked on. If you are a fabricator with experience in working with stainless steel, you should highlight your skills in stainless steel fabrication and list any relevant projects you have worked on.

In addition, you can also include a section on your resume that highlights your experience with specific welding and fabrication equipment. This will show potential employers that you are familiar with the latest equipment and that you are able to operate it safely and efficiently.

By including all of this information in your welding and fabrication resume, you will be able to create a resume that will showcase your skills and experience and land you the job you want.

| Skill | Description |

|---|---|

| MIG welding | A welding process that uses a continuously fed consumable wire electrode and a shielding gas to protect the weld pool from contamination. |

| TIG welding | A welding process that uses a non-consumable tungsten electrode to create an arc between the electrode and the base metal. |

| Stick welding | A welding process that uses a consumable electrode that is coated with a flux. |

| Flux-cored arc welding | A welding process that uses a continuously fed consumable electrode that is filled with a flux. |

| Plasma arc welding | A welding process that uses a plasma arc to melt the base metal. |

| Laser welding | A welding process that uses a laser beam to melt the base metal. |

| Cutting | A process that uses a cutting torch or plasma cutter to cut metal. |

| Bending | A process that uses a bending machine to bend metal. |

| Forming | A process that uses a forming machine to shape metal. |

| Rolling | A process that uses a rolling machine to reduce the thickness of metal. |

| Welding | A process that uses heat to join metal together. |

| Assembling | A process that joins components together to create a finished product. |

| Finishing | A process that gives a finished product a desired appearance or surface texture. |

Experience

In the context of a welding and fabrication resume, experience is paramount. This section of your resume should highlight your skills and abilities as a welder or fabricator, and it should include a list of your relevant work experience. When listing your experience, be sure to include the following information:

- Company name

- Job title

- Dates of employment

- Description of your responsibilities

- Skills and equipment used

- Projects worked on

By including all of this information, you will be able to create a welding and fabrication resume that showcases your experience and skills and lands you the job you want.

Here are some examples of welding and fabrication experience that you can include on your resume:

- Welded pipe on a variety of projects, including power plants, refineries, and pipelines.

- Fabricated structural steel for buildings, bridges, and other structures.

- Repaired and maintained welding and fabrication equipment.

- Supervised a team of welders and fabricators.

- Developed and implemented new welding and fabrication techniques.

By including this type of experience on your resume, you will be able to demonstrate to potential employers that you have the skills and experience necessary to be successful in the welding and fabrication industry.

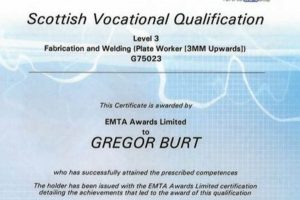

Certifications

Certifications are an important part of a welding and fabrication resume because they demonstrate to potential employers that you have the skills and knowledge necessary to perform your job safely and effectively. There are a variety of welding and fabrication certifications available, and the specific certifications that you need will depend on your job title and the industry in which you work. However, some of the most common welding and fabrication certifications include:

- AWS Certified Welder (CW)

- AWS Certified Welder-Inspector (CWI)

- AWS Certified Welding Supervisor (CWS)

- ASME Boiler and Pressure Vessel Code (BPVC) Certification

- National Institute for Certification in Engineering Technologies (NICET) Certification

Earning welding and fabrication certifications can be a great way to advance your career and increase your earning potential. By demonstrating your commitment to safety and quality, you can make yourself a more attractive candidate for employers and increase your chances of landing the job you want.

Here are some examples of how welding and fabrication certifications can benefit your career:

- Increased earning potential: Welders and fabricators with certifications can earn higher wages than those without certifications.

- Improved job opportunities: Welders and fabricators with certifications are more likely to be hired for high-paying jobs.

- Greater job security: Welders and fabricators with certifications are less likely to be laid off during economic downturns.

- Increased safety: Welders and fabricators with certifications are more likely to follow safe work practices and avoid accidents.

If you are interested in obtaining welding and fabrication certifications, there are a number of resources available to help you. You can find training courses at community colleges, trade schools, and online. You can also find certification exams through organizations such as the American Welding Society (AWS) and the National Institute for Certification in Engineering Technologies (NICET).

By investing in welding and fabrication certifications, you can improve your skills, increase your earning potential, and advance your career.

| Certification | Description |

|---|---|

| AWS Certified Welder (CW) | This certification demonstrates that the welder has the skills and knowledge necessary to perform a variety of welding tasks safely and effectively. |

| AWS Certified Welder-Inspector (CWI) | This certification demonstrates that the welder-inspector has the skills and knowledge necessary to inspect welds and ensure that they meet the requirements of the applicable welding code. |

| AWS Certified Welding Supervisor (CWS) | This certification demonstrates that the welding supervisor has the skills and knowledge necessary to supervise welding operations and ensure that they are performed safely and effectively. |

| ASME Boiler and Pressure Vessel Code (BPVC) Certification | This certification demonstrates that the welder has the skills and knowledge necessary to weld boilers and pressure vessels in accordance with the requirements of the ASME Boiler and Pressure Vessel Code. |

| National Institute for Certification in Engineering Technologies (NICET) Certification | This certification demonstrates that the welder has the skills and knowledge necessary to perform a variety of welding tasks in accordance with the requirements of the National Institute for Certification in Engineering Technologies. |

Education

A strong educational foundation is essential for a successful career in welding and fabrication. Welding and fabrication education programs provide students with the knowledge and skills they need to be safe and productive workers in the industry.

Welding education programs typically cover topics such as:

- Welding processes

- Welding equipment

- Welding safety

- Welding codes and standards

- Welding techniques

Fabrication education programs typically cover topics such as:

- Fabrication processes

- Fabrication equipment

- Fabrication safety

- Fabrication codes and standards

- Fabrication techniques

Students who complete welding and fabrication education programs are prepared to work in a variety of industries, including:

- Construction

- Manufacturing

- Shipbuilding

- Aerospace

- Automotive

Welding and fabrication education can be obtained through a variety of programs, including:

- Community colleges

- Trade schools

- Apprenticeship programs

- Online courses

The type of program that is best for you will depend on your individual needs and goals. If you are interested in a career in welding and fabrication, it is important to do your research and find a program that will provide you with the skills and knowledge you need to be successful.

Benefits of Welding and Fabrication Education

There are many benefits to obtaining a welding and fabrication education. Some of the benefits include:

- Increased earning potential: Welders and fabricators with education are more likely to earn higher wages than those without education.

- Improved job opportunities: Welders and fabricators with education are more likely to be hired for high-paying jobs.

- Greater job security: Welders and fabricators with education are less likely to be laid off during economic downturns.

- Increased safety: Welders and fabricators with education are more likely to follow safe work practices and avoid accidents.

- Career advancement: Welders and fabricators with education are more likely to advance to supervisory and management positions.

If you are interested in a career in welding and fabrication, it is important to consider the benefits of obtaining an education. A welding and fabrication education can help you increase your earning potential, improve your job opportunities, increase your job security, increase your safety, and advance your career.

| Education Level | Program Length | Cost | Job Outlook |

|---|---|---|---|

| Certificate | 6-12 months | $5,000-$10,000 | Good |

| Associate’s Degree | 2 years | $10,000-$20,000 | Very good |

| Bachelor’s Degree | 4 years | $20,000-$40,000 | Excellent |

Materials

In the context of a welding and fabrication resume, the materials used play a crucial role in showcasing the welder or fabricator’s skills and experience. Welding materials, such as electrodes, filler metals, and shielding gases, determine the quality and integrity of the welded joint. Fabrication materials, such as metals, plastics, and composites, influence the structural properties and functionality of the fabricated product.

By highlighting the specific materials used in previous projects, the welder or fabricator can demonstrate their proficiency in working with different materials and their ability to adapt to various industry requirements. For instance, a welder who has experience in welding exotic materials, such as titanium or Inconel, would be an asset to a company working on high-performance products. Similarly, a fabricator who is skilled in working with composite materials would be valuable in industries such as aerospace or automotive.

In addition to showcasing skills and experience, the materials used can also indicate the welder or fabricator’s knowledge of industry standards and best practices. For example, a welder who is familiar with the American Welding Society’s (AWS) D1.1 structural welding code would be able to select the appropriate welding materials and procedures to meet specific structural requirements.

Overall, the materials used in welding and fabrication are an important aspect of a welding and fabrication resume as they provide insights into the welder or fabricator’s skills, experience, and knowledge. By carefully selecting and highlighting the materials used in previous projects, welders and fabricators can create a resume that effectively showcases their capabilities and increases their chances of landing the job they want.

Table: Common Welding and Fabrication Materials

| Material | Welding Process | Fabrication Process |

|---|---|---|

| Steel | MIG welding, TIG welding, stick welding | Cutting, bending, forming, rolling, welding, assembling |

| Aluminum | MIG welding, TIG welding | Cutting, bending, forming, rolling, welding, assembling |

| Stainless steel | TIG welding, MIG welding, stick welding | Cutting, bending, forming, rolling, welding, assembling |

| Titanium | TIG welding, plasma arc welding | Cutting, forming, welding |

| Plastic | Plastic welding | Cutting, molding, forming |

| Composite materials | Adhesive bonding, mechanical fastening | Layup, curing, molding |

Industries

The industries in which a welder or fabricator has experience play a significant role in shaping the content of their resume. Different industries have specific requirements, standards, and materials, and highlighting relevant industry experience can demonstrate a welder or fabricator’s expertise and qualifications to potential employers.

- Construction: Welders and fabricators are in high demand in the construction industry, working on projects such as bridges, buildings, and pipelines. They may specialize in structural welding, pipe welding, or other construction-related welding processes.

- Manufacturing: Welders and fabricators are essential in the manufacturing industry, working in factories and production facilities to create a wide range of products, from automobiles and appliances to heavy machinery. They may specialize in production welding, robotic welding, or other manufacturing-related welding processes.

- Shipbuilding: Welders and fabricators play a crucial role in the shipbuilding industry, constructing and repairing ships and boats. They may specialize in marine welding, underwater welding, or other shipbuilding-related welding processes.

- Aerospace: Welders and fabricators in the aerospace industry work on aircraft and spacecraft, where precision and high-quality welds are critical. They may specialize in aerospace welding, exotic materials welding, or other aerospace-related welding processes.

By showcasing their experience in specific industries on their resume, welders and fabricators can demonstrate their familiarity with industry-specific requirements, standards, and materials. This can give them a competitive advantage over other candidates and increase their chances of landing the job they want.

Keywords

Keywords are an essential part of a welding and fabrication resume, as they help potential employers quickly and easily identify your skills and experience. When choosing keywords, it is important to think about the specific jobs you are applying for and the skills and experience that are most relevant to those jobs.

Some of the most common welding keywords include:

- MIG welding

- TIG welding

- Stick welding

- Plasma arc welding

- Laser welding

- Welding codes and standards

- Welding safety

Some of the most common fabrication keywords include:

- Cutting

- Bending

- Forming

- Rolling

- Welding

- Assembling

- Finishing

By including relevant keywords in your welding and fabrication resume, you can make it more likely that your resume will be seen by potential employers and that you will be called for an interview.

Here are some examples of how you can use keywords in your welding and fabrication resume:

- Welder with 5 years of experience in MIG welding, TIG welding, and stick welding.

- Fabricator with experience in cutting, bending, forming, rolling, welding, assembling, and finishing.

- Certified Welder with experience in welding codes and standards.

- Experienced in welding safety and have a clean safety record.

By using relevant keywords in your welding and fabrication resume, you can increase your chances of getting the job you want.

| Keyword | Description |

|---|---|

| MIG welding | A welding process that uses a continuously fed consumable wire electrode and a shielding gas to protect the weld pool from contamination. |

| TIG welding | A welding process that uses a non-consumable tungsten electrode to create an arc between the electrode and the base metal. |

| Stick welding | A welding process that uses a consumable electrode that is coated with a flux. |

| Plasma arc welding | A welding process that uses a plasma arc to melt the base metal. |

| Laser welding | A welding process that uses a laser beam to melt the base metal. |

| Welding codes and standards | A set of rules and regulations that govern the welding process. |

| Welding safety | The practice of protecting welders and others from the hazards associated with welding. |

| Cutting | A process that uses a cutting torch or plasma cutter to cut metal. |

| Bending | A process that uses a bending machine to bend metal. |

| Forming | A process that uses a forming machine to shape metal. |

| Rolling | A process that uses a rolling machine to reduce the thickness of metal. |

| Welding | A process that uses heat to join metal together. |

| Assembling | A process that joins components together to create a finished product. |

| Finishing | A process that gives a finished product a desired appearance or surface texture. |

FAQs on Welding and Fabrication Resumes

This section addresses frequently asked questions and aims to provide clear and informative answers to guide individuals in crafting effective welding and fabrication resumes.

Question 1: What are the key elements to include in a welding and fabrication resume?

A strong welding and fabrication resume should highlight relevant skills, experience, certifications, education, materials worked with, industries of expertise, and keywords tailored to the specific job requirements.

Question 2: How can I showcase my welding and fabrication skills effectively?

Quantify your accomplishments, provide specific examples of projects worked on, and emphasize the welding processes and equipment you are proficient in. Use action verbs and technical terminology to demonstrate your expertise.

Question 3: What certifications and licenses are valuable for welding and fabrication professionals?

Obtain industry-recognized certifications such as AWS Certified Welder (CW), AWS Certified Welder-Inspector (CWI), and AWS Certified Welding Supervisor (CWS). These credentials demonstrate your competence and adherence to industry standards.

Question 4: How should I highlight my education and training in welding and fabrication?

Include your educational qualifications, such as certificates, associate’s degrees, or bachelor’s degrees in welding or fabrication. Mention any specialized training or courses you have completed to enhance your skills.

Question 5: What is the importance of mentioning the materials worked with in a welding and fabrication resume?

Specify the types of materials you have experience working with, such as steel, aluminum, stainless steel, titanium, or composite materials. This demonstrates your versatility and adaptability to different industry requirements.

Question 6: How can I optimize my resume for specific job applications?

Tailor your resume to each job you apply for by incorporating keywords relevant to the job description. Research the company and industry to understand their specific needs and highlight your qualifications accordingly.

Summary: Crafting a compelling welding and fabrication resume requires attention to detail, highlighting your skills, experience, and qualifications. By following these guidelines and addressing common concerns, you can create a resume that effectively showcases your capabilities and increases your chances of success in the job market.

Transition: For further guidance on resume writing and career advancement in welding and fabrication, explore the following resources:

Welding and Fabrication Resume Tips

To enhance your welding and fabrication resume and stand out in the competitive job market, consider these valuable tips:

Tip 1: Showcase Your Skills and Experience

Highlight your welding and fabrication skills prominently, including specific processes, techniques, and equipment you are proficient in. Quantify your accomplishments and provide concrete examples of projects you have worked on.

Tip 2: Obtain Industry Certifications

Certifications demonstrate your competence and adherence to industry standards. Acquire certifications from reputable organizations such as the American Welding Society (AWS) to enhance your credibility and marketability.

Tip 3: Highlight Your Materials Expertise

Specify the types of materials you have experience working with, such as steel, aluminum, stainless steel, or composite materials. This demonstrates your versatility and adaptability to different industry requirements.

Tip 4: Emphasize Your Safety and Quality Standards

Welding and fabrication involve safety and quality consciousness. Emphasize your commitment to following safety protocols and maintaining high-quality standards in your work.

Tip 5: Tailor Your Resume to Specific Jobs

Research the companies and industries you are targeting and tailor your resume to match their specific needs and requirements. Highlight the skills and experience that are most relevant to the job you are applying for.

Tip 6: Use Action Verbs and Technical Terminology

Use strong action verbs to describe your accomplishments and technical terminology to demonstrate your expertise. This will make your resume more impactful and easier for potential employers to understand your capabilities.

Tip 7: Include a Professional Profile or Summary

Start your resume with a concise and compelling professional profile or summary that highlights your key skills, experience, and career goals. This will provide a quick overview of your qualifications to potential employers.

Tip 8: Proofread Carefully

Before submitting your resume, proofread it carefully for any errors in grammar, spelling, or formatting. A polished and error-free resume will make a positive impression on potential employers.

By following these tips, you can create a welding and fabrication resume that effectively showcases your skills, experience, and qualifications. This will increase your chances of landing the job you want and advancing your career in this dynamic industry.

Welding and Fabrication Resume

In the competitive landscape of the welding and fabrication industry, crafting a compelling resume is paramount to securing your desired job. By incorporating the strategies outlined in this comprehensive guide, you can create a resume that effectively showcases your skills, experience, and qualifications. From highlighting your welding and fabrication expertise to obtaining industry certifications and tailoring your resume to specific job applications, each step brings you closer to achieving your career aspirations.

Remember, a well-crafted welding and fabrication resume is not merely a document; it is a powerful tool that can unlock doors to new opportunities and propel your career forward. Embrace these tips, continue to develop your skills, and seize the possibilities that await you in the dynamic world of welding and fabrication.