What is mark steel fabrication? Mark steel fabrication is the process of shaping and forming steel to create a desired product. This can be done through a variety of methods, such as cutting, bending, welding, and machining.

Editor’s Note: Mark steel fabrication is an important topic to understand because it is used in a wide variety of industries, including construction, manufacturing, and transportation.

To help you better understand mark steel fabrication, we’ve put together this guide that covers the basics of the process, the different methods used, and the benefits of using mark steel fabrication.

Key Differences/Key Takeaways:

| Characteristic | Mark Steel Fabrication |

|---|---|

| Definition | The process of shaping and forming steel to create a desired product. |

| Methods | Cutting, bending, welding, and machining. |

| Benefits | Strong, durable, and cost-effective. |

Main Article Topics:

- The Basics of Mark Steel Fabrication

- The Different Methods of Mark Steel Fabrication

- The Benefits of Using Mark Steel Fabrication

Mark Steel Fabrication

Mark steel fabrication is a versatile and cost-effective process that can be used to create a wide variety of products. Here are 8 key aspects of mark steel fabrication:

- Process: Shaping and forming steel to create a desired product.

- Methods: Cutting, bending, welding, and machining.

- Materials: Steel, stainless steel, aluminum, and other metals.

- Products: Buildings, bridges, vehicles, machinery, and more.

- Benefits: Strong, durable, and cost-effective.

- Industries: Construction, manufacturing, transportation, and more.

- Quality: Determined by the skill of the fabricator and the quality of the materials used.

- Safety: Proper safety precautions must be taken when working with steel.

These key aspects provide a comprehensive overview of mark steel fabrication. By understanding these aspects, you can make informed decisions about when and how to use mark steel fabrication for your projects.

Process

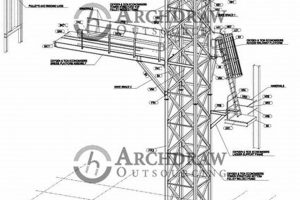

Mark steel fabrication is the process of shaping and forming steel to create a desired product. This process can be used to create a wide variety of products, from simple brackets to complex architectural structures. The process begins with the selection of the appropriate steel material. The steel is then cut, bent, welded, and machined to create the desired product.

The process of shaping and forming steel is a critical component of mark steel fabrication. Without this process, it would not be possible to create the wide variety of products that are made from steel. The process is also essential for ensuring that the products are strong, durable, and meet the required specifications.

There are a number of different methods that can be used to shape and form steel. The most common methods include cutting, bending, welding, and machining. Cutting is used to cut the steel to the desired size and shape. Bending is used to bend the steel into the desired shape. Welding is used to join two or more pieces of steel together. Machining is used to create precision parts from steel.

The process of shaping and forming steel is a complex one that requires skill and experience. However, it is a process that is essential for the production of a wide variety of products. By understanding the process, you can better appreciate the products that are made from steel and the skill of the fabricators who create them.

| Method | Description | Applications |

|---|---|---|

| Cutting | Cutting is used to cut the steel to the desired size and shape. | Cutting is used in a variety of applications, including the production of steel beams, plates, and bars. |

| Bending | Bending is used to bend the steel into the desired shape. | Bending is used in a variety of applications, including the production of steel frames, brackets, and supports. |

| Welding | Welding is used to join two or more pieces of steel together. | Welding is used in a variety of applications, including the production of steel bridges, buildings, and ships. |

| Machining | Machining is used to create precision parts from steel. | Machining is used in a variety of applications, including the production of steel gears, shafts, and bearings. |

Methods

Mark steel fabrication is a versatile process that involves shaping and forming steel to create a wide range of products. This process relies heavily on four key methods: cutting, bending, welding, and machining. Each of these methods plays a crucial role in transforming raw steel into the desired product.

Cutting is the process of dividing steel into smaller pieces or specific shapes. This can be done using various techniques, such as sawing, shearing, or laser cutting. Cutting is essential for creating the basic components of steel structures, such as beams, plates, and bars.

Bending is the process of shaping steel by applying force to create curves or angles. This is commonly achieved using specialized bending machines or presses. Bending is crucial for forming complex shapes, such as brackets, frames, and supports, which are essential components of many steel structures.

Welding is the process of joining two or more pieces of steel together by melting the metal at the point of contact. This creates a strong and permanent bond. Welding is widely used in mark steel fabrication to assemble complex structures, such as bridges, buildings, and ships.

Machining is the process of removing material from steel to create precise parts. This is typically done using machine tools, such as lathes, mills, and grinders. Machining is essential for creating components that require high levels of precision, such as gears, shafts, and bearings.

The combination of these four methods cutting, bending, welding, and machining allows mark steel fabricators to create a vast array of products, from simple brackets to complex architectural structures. These methods are essential for shaping and forming steel to meet the specific requirements of each project.

By understanding the importance and interrelationship of these methods, engineers and designers can work effectively with mark steel fabricators to achieve optimal results in their projects. The precise execution of these methods ensures the structural integrity, durability, and aesthetic appeal of steel fabrications.

In summary, the methods of cutting, bending, welding, and machining are the backbone of mark steel fabrication. These methods enable the transformation of raw steel into a wide range of products, contributing to the construction of essential infrastructure, machinery, and architectural marvels.

| Method | Description | Applications |

|---|---|---|

| Cutting | Dividing steel into smaller pieces or specific shapes. | Creating beams, plates, bars. |

| Bending | Shaping steel by applying force to create curves or angles. | Forming brackets, frames, supports. |

| Welding | Joining two or more pieces of steel together by melting the metal at the point of contact. | Assembling complex structures, such as bridges, buildings, ships. |

| Machining | Removing material from steel to create precise parts. | Creating gears, shafts, bearings. |

Materials

The materials used in mark steel fabrication play a critical role in determining the properties and performance of the final product. The most common materials used are steel, stainless steel, aluminum, and other metals. Each material has its own unique set of properties that make it suitable for different applications.

- Steel is the most common material used in mark steel fabrication. It is strong, durable, and relatively inexpensive. Steel is used in a wide variety of applications, including construction, manufacturing, and transportation.

- Stainless steel is a type of steel that is resistant to corrosion and rust. It is often used in applications where hygiene is important, such as in food processing and medical equipment.

- Aluminum is a lightweight and strong metal that is often used in aerospace and automotive applications. It is also used in construction and other industries where weight is a concern.

- Other metals, such as copper, brass, and titanium, are also used in mark steel fabrication for specific applications. These metals offer unique properties, such as high electrical conductivity or resistance to heat and corrosion.

The choice of material for a particular mark steel fabrication project depends on a number of factors, including the intended use of the product, the required strength and durability, and the budget. By understanding the properties of different metals, engineers and designers can select the right material for their project and ensure that the final product meets the required specifications.

Products

Mark steel fabrication plays a crucial role in the production of a wide range of products, including buildings, bridges, vehicles, and machinery. These products are essential for modern society, and mark steel fabrication is a key enabler of their production.

The connection between mark steel fabrication and these products is evident in the properties of steel itself. Steel is a strong, durable, and versatile material that can be shaped and formed into complex structures. This makes it ideal for use in a variety of applications, from structural supports to vehicle frames.

For example, steel is used in the construction of buildings because it can provide the necessary strength and support to withstand various loads and environmental conditions. In bridges, steel is used to create lightweight and durable structures that can span long distances. In vehicles, steel is used to create strong and safe frames that can protect occupants in the event of a collision. In machinery, steel is used to create components that are resistant to wear and tear, ensuring the longevity and reliability of the equipment.

The practical significance of understanding the connection between mark steel fabrication and these products lies in the ability to design and engineer structures and machines that are safe, efficient, and cost-effective. By understanding the properties of steel and the capabilities of mark steel fabrication, engineers and designers can optimize their designs to meet specific performance requirements.

In summary, mark steel fabrication is a critical process that enables the production of a wide range of products that are essential for modern society. The connection between mark steel fabrication and these products is based on the unique properties of steel and the ability to shape and form it into complex structures. Understanding this connection is crucial for designing and engineering safe, efficient, and cost-effective products.

Table: Examples of Mark Steel Fabrication Products

| Product | Application |

|---|---|

| Buildings | Structural supports, beams, columns, roofing |

| Bridges | Main spans, trusses, cables |

| Vehicles | Frames, chassis, panels |

| Machinery | Gears, shafts, bearings |

Benefits

Mark steel fabrication offers several key benefits, including strength, durability, and cost-effectiveness. These benefits make mark steel fabrication an attractive option for a wide range of applications, from construction and manufacturing to transportation and infrastructure.

The strength of steel is one of its most important benefits. Steel is able to withstand high loads without bending or breaking, making it an ideal material for structural applications. The durability of steel is another major benefit, as it is resistant to corrosion, rust, and other forms of deterioration. This makes steel an excellent choice for long-lasting applications, such as bridges and buildings.

In addition to its strength and durability, steel is also a cost-effective material. Steel is relatively inexpensive to produce, and it can be recycled, which further reduces its cost. This makes steel an attractive option for projects with limited budgets.

The combination of strength, durability, and cost-effectiveness makes mark steel fabrication an ideal choice for a wide range of applications. Engineers and designers can use mark steel fabrication to create structures and products that are strong, durable, and affordable.

Table: Benefits of Mark Steel Fabrication

| Benefit | Description |

|---|---|

| Strength | Steel is able to withstand high loads without bending or breaking. |

| Durability | Steel is resistant to corrosion, rust, and other forms of deterioration. |

| Cost-effectiveness | Steel is relatively inexpensive to produce and can be recycled. |

Industries

Mark steel fabrication is a versatile process that finds application in a diverse range of industries, including construction, manufacturing, transportation, and more. The connection between mark steel fabrication and these industries stems from the unique properties of steel and the ability to shape and form it into complex structures.

-

Construction:

In the construction industry, mark steel fabrication is used to create structural components such as beams, columns, and trusses. These components provide the necessary strength and support for buildings, bridges, and other structures. Steel’s strength-to-weight ratio makes it an ideal material for these applications, as it can withstand high loads without being excessively heavy.

-

Manufacturing:

Mark steel fabrication is also used extensively in the manufacturing industry. Steel is used to create a wide range of products, including machinery, tools, and equipment. Steel’s durability and resistance to wear and tear make it an excellent choice for these applications, as it can withstand harsh conditions and repeated use.

-

Transportation:

In the transportation industry, mark steel fabrication is used to create vehicles such as cars, trucks, and airplanes. Steel’s strength and ability to absorb impact make it an ideal material for these applications, as it can protect occupants in the event of a collision.

-

Other Industries:

Beyond these core industries, mark steel fabrication is also used in a variety of other industries, including energy, mining, and agriculture. Steel’s versatility and adaptability make it a valuable material for a wide range of applications.

The connection between mark steel fabrication and these industries highlights the importance of this process in modern society. Mark steel fabrication enables the production of a wide range of products and structures that are essential for our daily lives. By understanding the connection between mark steel fabrication and these industries, we can better appreciate the role that steel plays in shaping our world.

Quality

The quality of mark steel fabrication is directly tied to the skill of the fabricator and the quality of the materials used. A skilled fabricator with access to high-quality materials can produce a product that is strong, durable, and aesthetically pleasing. Conversely, a less skilled fabricator or poor-quality materials can result in a product that is weak, unreliable, and unattractive.

There are a number of factors that contribute to the skill of a fabricator, including training, experience, and attention to detail. A well-trained fabricator will have a deep understanding of the materials they are working with and the techniques required to shape and form them. They will also have the experience necessary to anticipate and avoid potential problems.

The quality of the materials used in mark steel fabrication is also critical. Steel is a versatile material, but it is not all created equal. Some steels are stronger and more durable than others. A fabricator who uses high-quality steel will be able to produce a product that is more likely to withstand the test of time.

The combination of a skilled fabricator and high-quality materials is essential for producing mark steel fabrication that meets the highest standards. By understanding the connection between quality and these two factors, engineers and designers can make informed decisions about the fabrication process and ensure that they are getting the best possible product for their money.

Real-Life Examples

There are many real-life examples that illustrate the importance of quality in mark steel fabrication. For instance, the Sydney Harbour Bridge is one of the most iconic steel structures in the world. It was built in the 1930s using high-quality steel and skilled fabrication techniques. As a result, the bridge has withstood the test of time and remains a vital part of Sydney’s infrastructure.

Another example is the Burj Khalifa, the tallest building in the world. The Burj Khalifa was built using a combination of high-strength steel and advanced fabrication techniques. This has resulted in a building that is both strong and lightweight, and able to withstand the extreme conditions of the desert environment.

These are just two examples of how quality mark steel fabrication can create structures that are both beautiful and functional. By understanding the importance of quality, engineers and designers can ensure that their projects are built to last.

Practical Significance

Understanding the connection between quality and mark steel fabrication is essential for engineers and designers. By understanding these factors, they can make informed decisions about the fabrication process and ensure that they are getting the best possible product for their money. This can lead to safer, more durable, and more aesthetically pleasing structures.

Safety

Mark steel fabrication involves working with heavy machinery and sharp materials, posing potential safety hazards. Understanding the connection between safety and mark steel fabrication is crucial to prevent accidents and ensure a safe working environment.

Safety precautions are essential in mark steel fabrication due to the inherent risks associated with working with steel. These risks include cuts, burns, eye injuries, and exposure to hazardous fumes. Proper safety precautions minimize these risks and protect workers.

Real-life examples demonstrate the severe consequences of neglecting safety in mark steel fabrication. In 2018, a worker in a steel fabrication shop suffered severe burns when molten metal splashed onto him due to improper handling of equipment. Another incident in 2019 involved a worker losing an eye due to flying debris during a cutting operation.

The practical significance of understanding the connection between safety and mark steel fabrication lies in preventing accidents and ensuring compliance with safety regulations. By implementing proper safety measures, such as wearing protective gear, using machinery correctly, and following established safety protocols, fabrication shops can create a safer workplace and avoid potential legal liabilities.

Key Insights:

- Mark steel fabrication involves inherent safety risks that must be addressed through proper safety precautions.

- Neglecting safety can lead to severe accidents and legal consequences.

- Understanding the connection between safety and mark steel fabrication is essential for preventing accidents and ensuring a safe working environment.

Safety Precautions in Mark Steel Fabrication:

| Hazard | Precaution |

|---|---|

| Cuts | Wear cut-resistant gloves and clothing. |

| Burns | Wear protective clothing and face shields when working with molten metal. |

| Eye injuries | Wear safety glasses or goggles when operating machinery or working with sharp materials. |

| Hazardous fumes | Ensure proper ventilation in the work area and use respirators when necessary. |

FAQs about Mark Steel Fabrication

This section addresses frequently asked questions about mark steel fabrication, providing concise and informative answers to common concerns or misconceptions.

Question 1: What is the difference between mark steel fabrication and welding?

Mark steel fabrication encompasses a wider range of processes than welding. Welding is a specific process that joins two pieces of metal by melting them together. Mark steel fabrication, on the other hand, includes cutting, bending, shaping, and assembling steel to create a desired product. Welding is often used as a part of mark steel fabrication, but it is not the only process involved.

Question 2: Is mark steel fabrication expensive?

The cost of mark steel fabrication can vary depending on the complexity of the project, the materials used, and the labor involved. However, steel is a relatively cost-effective material, and mark steel fabrication can be a cost-effective way to create strong and durable products.

Question 3: How long does mark steel fabrication take?

The time it takes to complete a mark steel fabrication project depends on the size and complexity of the project. Simple projects can be completed in a matter of days, while larger or more complex projects may take several weeks or even months.

Question 4: What are the benefits of using mark steel fabrication?

Mark steel fabrication offers several benefits, including strength, durability, cost-effectiveness, and versatility. Steel is a strong and durable material that can withstand high loads and harsh conditions. It is also relatively inexpensive to produce, and it can be recycled, which further reduces its cost. Mark steel fabrication can be used to create a wide range of products, from simple brackets to complex architectural structures.

Question 5: What are the applications of mark steel fabrication?

Mark steel fabrication is used in a wide range of applications, including construction, manufacturing, transportation, and infrastructure. Steel is used to create structural components for buildings, bridges, and other structures. It is also used to create machinery, tools, vehicles, and other products. Mark steel fabrication is an essential process for modern society, and it plays a vital role in the construction of our built environment.

Question 6: How can I find a reputable mark steel fabrication company?

When looking for a mark steel fabrication company, it is important to consider their experience, reputation, and quality of work. You should also ask for references from previous customers. By doing your research, you can find a reputable company that can provide you with high-quality mark steel fabrication services.

These are just a few of the most frequently asked questions about mark steel fabrication. By understanding the answers to these questions, you can make informed decisions about when and how to use mark steel fabrication for your projects.

To learn more about mark steel fabrication, please visit our website or contact us directly. We would be happy to answer any questions you may have and help you find the best solution for your needs.

Mark Steel Fabrication Tips

Mark steel fabrication is a complex and demanding process that requires skill, precision, and attention to detail. By following these tips, you can ensure that your mark steel fabrication projects are successful and meet the highest standards of quality.

Tip 1: Choose the right materials.

The type of steel you use will have a significant impact on the strength, durability, and cost of your finished product. Consider the specific requirements of your project and select the steel grade that best meets those needs.

Tip 2: Use the right tools and equipment.

Mark steel fabrication requires a variety of specialized tools and equipment. Make sure you have the right tools for the job and that they are in good working condition.

Tip 3: Follow the proper safety procedures.

Mark steel fabrication can be dangerous if proper safety precautions are not followed. Always wear appropriate safety gear, such as gloves, eye protection, and a hard hat. Be aware of your surroundings and take precautions to avoid accidents.

Tip 4: Get the proper training.

If you are new to mark steel fabrication, it is important to get the proper training. This will help you to learn the basics of the process and to avoid making mistakes.

Tip 5: Work with a reputable fabricator.

If you do not have the experience or expertise to fabricate steel yourself, it is important to work with a reputable fabricator. A reputable fabricator will have the skills and experience necessary to produce high-quality products that meet your specifications.

Summary of key takeaways or benefits:

- Choosing the right materials, tools, and equipment can help you to ensure the success of your mark steel fabrication projects.

- Following proper safety procedures is essential to avoid accidents and injuries.

- Getting the proper training can help you to learn the basics of mark steel fabrication and to avoid making mistakes.

- Working with a reputable fabricator can help you to ensure that your products are manufactured to the highest standards of quality.

Transition to the article’s conclusion:

By following these tips, you can improve the quality of your mark steel fabrication projects and ensure that they are completed safely and efficiently.

Conclusion

Mark steel fabrication is a vital process in the construction, manufacturing, and transportation industries. It is used to create a wide range of products, from simple brackets to complex architectural structures. Mark steel fabrication is a complex and demanding process, but by following best practices and working with a reputable fabricator, you can ensure that your projects are successful and meet the highest standards of quality.

The future of mark steel fabrication is bright. As the demand for steel products continues to grow, so too will the need for skilled fabricators. By investing in training and education, we can ensure that the next generation of fabricators is equipped with the skills and knowledge necessary to meet the challenges of the future.

Mark steel fabrication is an essential part of our modern world. It is used to create the buildings we live in, the bridges we drive on, and the vehicles we use to get around. By understanding the importance of mark steel fabrication, we can appreciate the skill and craftsmanship that goes into creating the products that we rely on every day.