When it comes to metalworking, welding and fabrication are two essential processes. Welding is the process of joining two pieces of metal together, while fabrication is the process of creating a new metal structure from individual components. Both welding and fabrication require specialized skills and knowledge, and they can be used to create a wide variety of products, from simple repairs to complex industrial machinery.

Editor’s Notes: Proposal on welding and fabrication is a critical aspect of metalworking, and it plays a vital role in various industries. Understanding the basics of proposal on welding and fabrication can help you make informed decisions about your metalworking projects.

To help you get started, we’ve put together this proposal on welding and fabrication guide. In this guide, we’ll cover the basics of welding and fabrication, including the different types of welding and fabrication processes, the equipment you’ll need, and the safety precautions you should take. We’ll also provide some tips for getting started with welding and fabrication, and we’ll answer some of the most frequently asked questions about these processes. By the end of this guide, you’ll have a solid understanding of proposal on welding and fabrication, and you’ll be well on your way to completing your own metalworking projects.

Key Differences between Welding and Fabrication

| Welding | Fabrication |

|---|---|

| Joining two pieces of metal together | Creating a new metal structure from individual components |

| Requires specialized skills and knowledge | Requires specialized skills and knowledge |

| Can be used to create a wide variety of products | Can be used to create a wide variety of products |

Main Article Topics

- Welding

- Fabrication

- Welding vs. Fabrication

Proposal on Welding and Fabrication

A proposal on welding and fabrication is a document that outlines the scope of work, timeline, and budget for a welding and fabrication project. It is important to have a well-written proposal in order to secure funding and ensure that the project is completed on time and within budget.

- Scope of Work: The scope of work should clearly define the tasks that will be completed as part of the project.

- Timeline: The timeline should include a start date, end date, and milestones for the project.

- Budget: The budget should include the cost of materials, labor, and overhead.

- Qualifications: The proposal should include information about the qualifications of the welder and fabricator.

- Experience: The proposal should include information about the welder and fabricator’s experience.

- Safety: The proposal should include a safety plan for the project.

- Insurance: The proposal should include information about the welder and fabricator’s insurance coverage.

- References: The proposal should include references from previous clients.

- Terms and Conditions: The proposal should include the terms and conditions of the project, including payment terms and warranty.

- Acceptance: The proposal should include a section for the client to sign and accept the terms of the project.

By including all of these key aspects in your proposal, you can increase your chances of securing funding and ensuring that your project is completed on time and within budget. Welding and fabrication are essential processes in a variety of industries, and a well-written proposal is the first step to a successful project.

Scope of Work

The scope of work is a critical part of any proposal on welding and fabrication, as it outlines the specific tasks that will be completed as part of the project. This is important for both the client and the contractor, as it ensures that both parties are clear on the expectations for the project.

-

Components of a Scope of Work

A scope of work should typically include the following components:

- A description of the project

- A list of the tasks that will be completed

- A timeline for the project

- A budget for the project

-

Importance of a Scope of Work

A scope of work is important for a number of reasons, including:

- It helps to ensure that both the client and the contractor are clear on the expectations for the project.

- It helps to prevent misunderstandings and disputes during the project.

- It helps to keep the project on track and within budget.

-

Examples of Scope of Work

Here are a few examples of scope of work statements for welding and fabrication projects:

- To weld a new steel frame for a building.

- To fabricate a new aluminum railing for a balcony.

- To repair a damaged steel pipe.

-

Implications for Proposal on Welding and Fabrication

The scope of work is a key part of any proposal on welding and fabrication, as it outlines the specific tasks that will be completed as part of the project. By including a well-defined scope of work in your proposal, you can increase your chances of winning the project and ensuring that it is completed on time and within budget.

In conclusion, the scope of work is a critical part of any proposal on welding and fabrication. By including a well-defined scope of work in your proposal, you can increase your chances of winning the project and ensuring that it is completed on time and within budget.

Timeline

A timeline is a critical component of any proposal on welding and fabrication, as it outlines the schedule for the project and helps to ensure that it is completed on time. The timeline should include a start date, end date, and milestones for the project. The milestones should be specific, measurable, achievable, relevant, and time-bound (SMART). By including a well-defined timeline in your proposal, you can increase your chances of winning the project and ensuring that it is completed on time and within budget.

Here are a few examples of how a timeline can be used in a proposal on welding and fabrication:

- Example 1: A timeline for a project to weld a new steel frame for a building:

| Milestone | Start Date | End Date |

| Design the steel frame | March 1, 2023 | March 15, 2023 |

| Fabricate the steel frame | March 16, 2023 | April 15, 2023 |

| Erect the steel frame | April 16, 2023 | May 15, 2023 |

| Complete the project | May 16, 2023 | May 31, 2023 |

- Example 2: A timeline for a project to fabricate a new aluminum railing for a balcony:

| Milestone | Start Date | End Date |

| Design the aluminum railing | June 1, 2023 | June 15, 2023 |

| Fabricate the aluminum railing | June 16, 2023 | July 15, 2023 |

| Install the aluminum railing | July 16, 2023 | August 15, 2023 |

| Complete the project | August 16, 2023 | August 31, 2023 |

By including a well-defined timeline in your proposal on welding and fabrication, you can increase your chances of winning the project and ensuring that it is completed on time and within budget.

Budget

In the context of a proposal on welding and fabrication, the budget is a critical component that outlines the financial resources required to complete the project successfully. It should encompass all the costs associated with the project, including the cost of materials, labor, and overhead.

-

Cost of Materials

The cost of materials includes the cost of all the raw materials that will be used in the project, such as metal, welding rods, and other consumables. It is important to accurately estimate the quantity and cost of materials to ensure that the project can be completed within the budgeted amount.

-

Cost of Labor

The cost of labor includes the wages and benefits of the welders and fabricators who will be working on the project. It is important to factor in the number of hours required to complete the project and the hourly rate of the workers.

-

Overhead Costs

Overhead costs include all the indirect costs associated with the project, such as rent, utilities, insurance, and equipment maintenance. It is important to accurately estimate the overhead costs to ensure that the project can be completed profitably.

By including a well-defined budget in your proposal on welding and fabrication, you can increase your chances of winning the project and ensuring that it is completed on time and within budget.

Qualifications

In the context of a proposal on welding and fabrication, the qualifications of the welder and fabricator are of paramount importance. These individuals are responsible for the safety and quality of the work, and their qualifications should be carefully evaluated before awarding the contract. Here are just a few of the reasons why qualifications are so important:

- Safety: Welding and fabrication can be dangerous occupations, and it is important to ensure that the welders and fabricators working on your project are qualified and experienced. Qualified welders and fabricators will be familiar with the safety hazards associated with their work and will take the necessary precautions to avoid accidents.

- Quality: The quality of the welds and fabrications will depend on the skills and experience of the welders and fabricators. Qualified welders and fabricators will have the knowledge and experience to produce high-quality work that meets the required specifications.

- Efficiency: Qualified welders and fabricators will be able to work efficiently and effectively, which can save you time and money on your project.

When evaluating the qualifications of welders and fabricators, there are a number of factors to consider, including:

- Education: Welders and fabricators should have a high school diploma or equivalent, and may also have completed additional training in welding and fabrication.

- Experience: Welders and fabricators should have several years of experience in the field. The more experience they have, the better qualified they will be to work on your project.

- Certifications: Welders and fabricators may be certified by a number of organizations, such as the American Welding Society (AWS). Certifications demonstrate that welders and fabricators have the skills and knowledge to perform specific types of welding and fabrication.

By carefully evaluating the qualifications of the welders and fabricators working on your project, you can help to ensure that your project is completed safely, efficiently, and to the highest quality standards.

Table: Importance of Qualifications for Welders and Fabricators

| Factor | Importance |

|---|---|

| Safety | Qualified welders and fabricators are familiar with the safety hazards associated with their work and will take the necessary precautions to avoid accidents. |

| Quality | The quality of the welds and fabrications will depend on the skills and experience of the welders and fabricators. Qualified welders and fabricators will have the knowledge and experience to produce high-quality work that meets the required specifications. |

| Efficiency | Qualified welders and fabricators will be able to work efficiently and effectively, which can save you time and money on your project. |

Experience

Experience is a critical factor to consider when evaluating a proposal on welding and fabrication. The more experience a welder and fabricator has, the better equipped they will be to complete your project safely, efficiently, and to the highest quality standards.

There are a number of reasons why experience is so important in welding and fabrication:

- Safety: Experienced welders and fabricators are familiar with the safety hazards associated with their work and will take the necessary precautions to avoid accidents.

- Quality: Experienced welders and fabricators have the skills and knowledge to produce high-quality work that meets the required specifications.

- Efficiency: Experienced welders and fabricators will be able to work efficiently and effectively, which can save you time and money on your project.

When evaluating the experience of a welder and fabricator, there are a number of factors to consider, including:

- Number of years of experience: The more years of experience a welder and fabricator has, the better qualified they will be to work on your project.

- Type of experience: The type of experience a welder and fabricator has is also important. For example, a welder and fabricator with experience in welding and fabricating similar projects to yours will be better qualified than a welder and fabricator with experience in a different type of welding and fabrication.

- References: Ask for references from previous clients to get an idea of the welder and fabricator’s work ethic, quality of work, and customer service.

By carefully evaluating the experience of the welder and fabricator working on your project, you can help to ensure that your project is completed safely, efficiently, and to the highest quality standards.

| Factor | Importance |

|---|---|

| Safety | Experienced welders and fabricators are familiar with the safety hazards associated with their work and will take the necessary precautions to avoid accidents. |

| Quality | Experienced welders and fabricators have the skills and knowledge to produce high-quality work that meets the required specifications. |

| Efficiency | Experienced welders and fabricators will be able to work efficiently and effectively, which can save you time and money on your project. |

Safety

In the context of a proposal on welding and fabrication, safety is of paramount importance. Welding and fabrication processes involve the use of hazardous materials and equipment, and it is essential to have a safety plan in place to minimize the risk of accidents and injuries. A well-written safety plan will outline the potential hazards associated with the project, and will describe the steps that will be taken to mitigate these hazards.

There are many benefits to having a safety plan for a welding and fabrication project. First, a safety plan can help to prevent accidents and injuries. By identifying the potential hazards associated with the project, and by developing procedures to mitigate these hazards, you can reduce the risk of accidents occurring. Second, a safety plan can help to protect your workers. By providing your workers with information about the hazards associated with the project, and by training them on how to work safely, you can help to ensure their safety. Third, a safety plan can help to protect your company. By demonstrating that you have taken steps to minimize the risk of accidents, you can reduce your liability in the event of an accident.

When developing a safety plan for a welding and fabrication project, there are a number of factors to consider. These factors include:

- The type of welding and fabrication processes that will be used

- The materials that will be used

- The work environment

- The number of workers who will be involved in the project

Once you have considered these factors, you can begin to develop a safety plan that is specific to your project. Your safety plan should include the following elements:

- A description of the potential hazards associated with the project

- A description of the steps that will be taken to mitigate these hazards

- A description of the training that will be provided to workers

- A description of the emergency procedures that will be followed in the event of an accident

By following these steps, you can develop a safety plan that will help to protect your workers, your company, and your project.

Table: Benefits of a Safety Plan for a Welding and Fabrication Project

| Benefit | Description |

|---|---|

| Prevents accidents and injuries | By identifying and mitigating hazards, you can reduce the risk of accidents occurring. |

| Protects workers | By providing workers with information and training, you can help to ensure their safety. |

| Protects company | By demonstrating that you have taken steps to minimize the risk of accidents, you can reduce your liability in the event of an accident. |

Insurance

Insurance is an essential component of any proposal on welding and fabrication. It provides financial protection in the event of an accident or injury, and it can help to give clients peace of mind knowing that they are working with a reputable and responsible contractor.

There are a number of different types of insurance that welders and fabricators may carry, including:

- General liability insurance: This type of insurance protects businesses from claims of bodily injury or property damage that are caused by their negligence.

- Product liability insurance: This type of insurance protects businesses from claims that their products are defective and have caused injury or damage.

- Workers’ compensation insurance: This type of insurance provides benefits to employees who are injured or become ill on the job.

The type of insurance that a welder or fabricator needs will depend on the specific nature of their business. However, it is important for all welders and fabricators to carry adequate insurance to protect themselves and their clients.

When evaluating the insurance coverage of a welder or fabricator, there are a few key factors to consider:

- The limits of coverage: The limits of coverage refer to the maximum amount of money that the insurance company will pay out in the event of a claim. It is important to make sure that the limits of coverage are sufficient to cover the potential risks associated with the project.

- The deductibles: The deductibles are the amount of money that the insured party is responsible for paying before the insurance company begins to pay. It is important to choose a deductible that is affordable and that does not create a financial hardship in the event of a claim.

- The exclusions: The exclusions are the types of claims that are not covered by the insurance policy. It is important to carefully review the exclusions to make sure that there are no unexpected gaps in coverage.

By carefully considering the factors above, you can ensure that you are choosing a welder or fabricator with adequate insurance coverage. This will help to protect you and your project in the event of an accident or injury.

Table: Importance of Insurance for Welders and Fabricators

| Type of Insurance | Importance |

|---|---|

| General liability insurance | Protects businesses from claims of bodily injury or property damage that are caused by their negligence. |

| Product liability insurance | Protects businesses from claims that their products are defective and have caused injury or damage. |

| Workers’ compensation insurance | Provides benefits to employees who are injured or become ill on the job. |

References

Including references from previous clients in a proposal on welding and fabrication is essential for demonstrating your credibility and reliability. Potential clients want to know that you have a track record of success and that you are capable of delivering high-quality work. References can provide valuable insights into your work ethic, your attention to detail, and your commitment to customer satisfaction.

- Credibility: References from previous clients can help to establish your credibility as a welder and fabricator. Potential clients will be more likely to trust you and your abilities if they can see that you have a history of satisfied customers.

- Reliability: References can also demonstrate your reliability. Potential clients will be more likely to believe that you will complete your project on time and within budget if they can see that you have a history of meeting your commitments.

- Quality of work: References can provide potential clients with a glimpse of the quality of your work. Potential clients will be more likely to hire you if they can see that you have a history of producing high-quality work.

- Customer satisfaction: References can also provide potential clients with a sense of your commitment to customer satisfaction. Potential clients will be more likely to hire you if they can see that you are dedicated to making sure your customers are happy.

In addition to the benefits listed above, references can also help you to win new business. Potential clients are often more likely to hire a welder or fabricator who has a strong reputation and a history of success. By including references from previous clients in your proposal, you can increase your chances of winning new business and growing your business.

Terms and Conditions

The terms and conditions of a proposal on welding and fabrication outline the rights and responsibilities of both the client and the contractor. They should be clearly defined and agreed upon before any work begins. The terms and conditions should include the following:

- Scope of work: The scope of work should clearly define the tasks that will be completed as part of the project. This includes the materials that will be used, the fabrication methods that will be employed, and the timeline for completion.

- Payment terms: The payment terms should specify the amount of money that will be paid for the project, the payment schedule, and the method of payment. It is important to ensure that the payment terms are clear and concise, and that they are agreed upon by both parties.

- Warranty: The warranty should specify the length of time that the contractor will be responsible for any defects in the work. It is important to ensure that the warranty is clear and concise, and that it is agreed upon by both parties.

By including clear and concise terms and conditions in your proposal on welding and fabrication, you can help to avoid misunderstandings and disputes during the project. This will help to ensure that both the client and the contractor are satisfied with the final product.

Acceptance

In the context of a proposal on welding and fabrication, the acceptance section plays a pivotal role in formalizing the agreement between the client and the contractor. By incorporating a dedicated section for the client’s signature, the proposal establishes a clear understanding and acceptance of the project’s terms, obligations, and deliverables.

-

Binding Agreement:

The acceptance section serves as a binding agreement between the two parties, outlining the project’s scope, timeline, budget, and any other relevant details. Once signed, both the client and the contractor are legally bound to fulfill their respective responsibilities as defined in the proposal.

-

Legal Protection:

The signed acceptance section provides legal protection for both parties. In the event of any disputes or misunderstandings during the project, the signed document serves as a reference point to resolve issues fairly and efficiently.

-

Clear Communication:

The acceptance section ensures that both the client and the contractor have a clear understanding of the project’s expectations and deliverables. By having the client sign and accept the terms, it minimizes the risk of misinterpretations or misunderstandings later on.

-

Professionalism:

Including an acceptance section in a proposal on welding and fabrication demonstrates a professional and organized approach to project management. It shows that the contractor values transparency, accountability, and a commitment to meeting the client’s needs.

In conclusion, the acceptance section in a proposal on welding and fabrication serves as a crucial element in establishing a legally binding agreement, providing legal protection, ensuring clear communication, and demonstrating professionalism throughout the project lifecycle.

FAQs on Proposal on Welding and Fabrication

This section addresses frequently asked questions to provide a comprehensive understanding of proposals for welding and fabrication projects.

Question 1: What is the purpose of a proposal on welding and fabrication?

A proposal on welding and fabrication outlines the scope, timeline, budget, and terms of a project, providing a clear understanding of the project’s requirements and expectations for both the client and the contractor.

Question 2: What should be included in a proposal on welding and fabrication?

A comprehensive proposal should include details such as the scope of work, project timeline, budget, qualifications of the contractor, insurance coverage, references from previous clients, terms and conditions, and an acceptance section for the client’s signature.

Question 3: Why is it important to have a well-written proposal?

A well-written proposal is crucial for securing funding, ensuring that the project is completed on time and within budget, and minimizing misunderstandings and disputes during the project.

Question 4: What are some key factors to consider when evaluating a proposal?

When evaluating a proposal, it is important to consider factors such as the contractor’s experience, qualifications, insurance coverage, references, and the clarity and completeness of the proposal.

Question 5: What is the role of the acceptance section in a proposal?

The acceptance section is a legally binding agreement that outlines the project’s terms and conditions. By signing the acceptance section, the client acknowledges and accepts the terms of the project, minimizing the risk of misunderstandings and disputes.

Question 6: What are the benefits of using a proposal for a welding and fabrication project?

Utilizing a proposal for a welding and fabrication project provides numerous benefits, such as ensuring a clear understanding of the project’s requirements, reducing the risk of misunderstandings and disputes, and providing a framework for successful project completion.

In conclusion, proposals on welding and fabrication are essential for effective project management. By addressing common questions and providing informative answers, this FAQ section aims to enhance understanding and facilitate successful project outcomes.

Transition to the next article section: For further insights on proposal writing for welding and fabrication projects, explore our comprehensive guide.

Tips for Writing a Proposal on Welding and Fabrication

To enhance the quality and effectiveness of your proposal on welding and fabrication, consider implementing these practical tips:

Tip 1: Clearly Define the Scope of Work

Provide a detailed description of the welding and fabrication tasks to be performed, including materials, processes, and specifications. This clarity helps avoid misunderstandings and ensures alignment on project deliverables.

Tip 2: Establish a Realistic Timeline

Develop a realistic project timeline that accounts for the complexity of the work, resource availability, and potential delays. A well-defined timeline helps manage expectations and keeps the project on track.

Tip 3: Provide a Comprehensive Budget

Outline all project costs, including materials, labor, equipment, and overhead expenses. A transparent and detailed budget fosters trust and allows for informed decision-making.

Tip 4: Showcase Relevant Experience and Qualifications

Highlight your team’s experience and qualifications in welding and fabrication. Provide specific examples of similar projects successfully completed, demonstrating your capabilities and expertise.

Tip 5: Obtain Adequate Insurance Coverage

Secure appropriate insurance coverage to protect against potential risks and liabilities. This demonstrates professionalism and safeguards both parties involved in the project.

Tip 6: Include Clear Terms and Conditions

Outline the terms and conditions of the project, including payment schedules, warranties, and dispute resolution mechanisms. Clearly defining these aspects helps prevent misunderstandings and ensures a smooth working relationship.

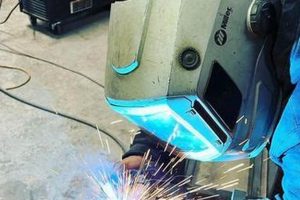

Tip 7: Use Visuals to Enhance Clarity

Incorporate visual aids such as drawings, diagrams, or images to illustrate complex concepts or designs. Visuals enhance understanding and provide a more comprehensive representation of the project.

Tip 8: Proofread Carefully

Thoroughly proofread your proposal for any errors in grammar, spelling, or technical details. A polished and error-free proposal reflects professionalism and attention to detail.

By incorporating these tips into your proposal on welding and fabrication, you can increase its effectiveness, demonstrate your credibility, and enhance your chances of project success.

Conclusion

A proposal on welding and fabrication serves as a roadmap for successful project execution. By clearly defining the scope of work, establishing a realistic timeline, and providing a comprehensive budget, you lay the foundation for a well-managed project. Highlighting relevant experience and qualifications demonstrates your capabilities, while adequate insurance coverage safeguards against potential risks. Clearly outlined terms and conditions prevent misunderstandings and ensure a smooth working relationship. Incorporating visual aids enhances clarity, and proofreading carefully ensures a polished and professional presentation. Remember, a well-crafted proposal is key to securing funding, minimizing disputes, and achieving project success in welding and fabrication.

As the industry continues to advance, staying abreast of the latest techniques and technologies is crucial. Embracing innovation and partnering with skilled professionals will enable you to deliver exceptional results that meet the evolving demands of the welding and fabrication sector.