Wondering about “r&j welding and metal fabrication“? It’s an art form that seamlessly blends creativity and expertise, transforming ordinary metal into extraordinary masterpieces. Our team at “r&j welding and metal fabrication” is passionate about delivering exceptional craftsmanship, forging durable and visually stunning creations that stand the test of time.

Editor’s Notes: “r&j welding and metal fabrication” is an essential topic for homeowners, businesses, and anyone seeking high-quality metalwork. With its versatility and durability, metal fabrication plays a crucial role in various industries, including construction, automotive, and manufacturing.

After extensive analysis and research, we’ve compiled this comprehensive guide to help you understand the intricacies of “r&j welding and metal fabrication“. Whether you’re planning a home renovation, starting a fabrication project, or simply curious about this fascinating field, this article will provide valuable insights and expert advice.

Key Differences or Key Takeaways:

| Welding | Metal Fabrication |

|---|---|

| Process of joining metal pieces | broader term that encompasses welding, cutting, bending, and shaping metal |

| Requires specialized equipment and skills | Can involve a wider range of materials and techniques |

| Used in construction, manufacturing, and repair | Used in industries such as automotive, aerospace, and shipbuilding |

Transition to main article topics:

r&j welding and metal fabrication

When it comes to “r&j welding and metal fabrication,” there are several key aspects that define this field and contribute to its importance. Let’s explore nine of them:

- Craftsmanship: The art of skilled metalworking

- Precision: Accuracy and attention to detail

- Durability: Creating structures and products that withstand wear and tear

- Versatility: Applicable in various industries, from construction to automotive

- Customization: Tailoring metalwork to specific needs and designs

- Safety: Adhering to industry standards and regulations

- Innovation: Continuously developing new techniques and applications

- Collaboration: Working closely with clients, engineers, and architects

- Sustainability: Using eco-friendly practices and materials

These aspects are interconnected and essential for understanding the significance of “r&j welding and metal fabrication.” For instance, craftsmanship and precision are crucial for creating high-quality products, while durability ensures they can withstand the test of time. Versatility allows metal fabrication to be used in diverse industries, and customization enables the creation of unique and tailored solutions. Safety is paramount to protect workers and ensure the integrity of structures, while innovation drives progress and efficiency. Collaboration fosters teamwork and ensures that projects meet client expectations. Finally, sustainability promotes responsible practices that protect the environment.

Craftsmanship

Craftsmanship, the art of skilled metalworking, is the cornerstone of “r&j welding and metal fabrication“. It encompasses the knowledge, skill, and experience required to transform raw metal into functional and aesthetically pleasing structures and products.

Craftsmanship is essential for achieving the precision, durability, and customization that are hallmarks of “r&j welding and metal fabrication“. Skilled metalworkers possess a deep understanding of metal properties, welding techniques, and fabrication processes. They take pride in their work, paying meticulous attention to detail and ensuring that every piece meets the highest standards of quality.

For instance, in the construction industry, skilled metalworkers are responsible for creating structural components, such as beams, columns, and staircases, that are both strong and visually appealing. In the automotive industry, they craft custom parts and components that enhance performance and durability. In the art world, metalworkers create sculptures and decorative pieces that are both functional and beautiful.

| Importance of Craftsmanship in “r&j welding and metal fabrication” | Real-Life Examples |

|---|---|

| Ensures precision and accuracy | Precision-engineered components for medical devices |

| Enhances durability and longevity | Durable metal structures for bridges and skyscrapers |

| Enables customization and personalization | Custom-fabricated metalwork for homes and businesses |

Understanding the connection between craftsmanship and “r&j welding and metal fabrication” is crucial for appreciating the value and importance of this field. It highlights the human element behind the creation of metal structures and products, showcasing the skill and dedication of the artisans who bring these designs to life.

Precision

In the realm of “r&j welding and metal fabrication,” precision is paramount. It encompasses the accuracy and attention to detail that are essential for creating high-quality, reliable, and aesthetically pleasing metal structures and products.

-

Dimensional Accuracy:

Precision in “r&j welding and metal fabrication” begins with dimensional accuracy, ensuring that metal components meet exact specifications. This is crucial in industries such as aerospace, where even minor deviations can compromise safety and performance. Skilled metalworkers use specialized tools and techniques to achieve precise measurements and tolerances.

-

Alignment and Fit:

Precision also extends to the alignment and fit of metal components. Whether it’s aligning structural beams in a building or fitting intricate parts in a machine, accurate alignment is essential for proper functioning and long-term durability. Metalworkers employ jigs, fixtures, and precision measuring tools to ensure perfect alignment and seamless fit.

-

Weld Quality:

Precision welding techniques are crucial for creating strong and reliable metal joints. Skilled welders use specialized equipment and followto achieve precise weld penetration, fusion, and bead geometry. This ensures the integrity and longevity of welded structures, from bridges to pressure vessels.

-

Surface Finish:

Attention to detail extends to the surface finish of metal fabrications. Precision grinding, polishing, and other finishing techniques are used to achieve the desired surface texture, whether it’s a smooth, reflective finish for aesthetic purposes or a rough, textured finish for enhanced grip or functionality.

By embracing precision in all aspects of “r&j welding and metal fabrication,” skilled metalworkers create structures and products that are not only functional and durable but also visually appealing and precise. Precision is the foundation upon which the reputation of “r&j welding and metal fabrication” is built, ensuring the highest standards of quality and craftsmanship.

Durability

In the realm of “r&j welding and metal fabrication,” durability is of paramount importance. It encompasses the ability of metal structures and products to withstand wear, tear, and harsh environmental conditions, ensuring longevity and reliability.

The durability of metal fabrications is influenced by several factors, including:

- Material Selection: The choice of metal alloys plays a crucial role in determining the durability of a fabrication. Skilled metalworkers carefully consider factors such as strength, corrosion resistance, and wear resistance when selecting materials for specific applications.

- Design and Engineering: Proper design and engineering practices ensure that metal structures can withstand the anticipated loads and stresses they will encounter during their service life. This involves careful consideration of factors such as load distribution, stress analysis, and fatigue resistance.

- Fabrication Techniques: The fabrication techniques used have a significant impact on the durability of metal products. Skilled metalworkers employ precise welding techniques, proper heat treatment, and surface treatments to enhance the strength and longevity of their creations.

- Quality Control: Stringent quality control measures are essential to ensure the durability of metal fabrications. This involves rigorous inspections, testing, and documentation throughout the fabrication process to identify and address any potential weaknesses or defects.

The durability of “r&j welding and metal fabrication” products is evident in various real-life applications:

- Construction: Metal structures used in buildings, bridges, and other infrastructure projects are designed to withstand decades of exposure to weather, seismic forces, and heavy loads.

- Automotive: Metal components in vehicles, such as chassis, suspension systems, and engine blocks, are engineered to endure the rigors of daily use and demanding driving conditions.

- Industrial Machinery: Metal fabrications used in industrial machinery are subjected to extreme temperatures, heavy loads, and corrosive environments, yet they must maintain their durability to ensure reliable operation.

Understanding the connection between durability and “r&j welding and metal fabrication” is crucial for several reasons:

- Ensures Safety and Reliability: Durable metal structures and products are essential for ensuring the safety and reliability of buildings, infrastructure, and machinery.

- Reduces Maintenance Costs: Durable fabrications require less frequent maintenance and repairs, leading to reduced operational costs over the long term.

- Enhances Sustainability: Durable products have a longer lifespan, reducing the need for frequent replacements and contributing to environmental sustainability.

By embracing durability in “r&j welding and metal fabrication,” skilled metalworkers create structures and products that stand the test of time, ensuring safety, reliability, cost-effectiveness, and sustainability.

Versatility

The versatility of “r&j welding and metal fabrication” stems from the inherent adaptability and wide-ranging applications of metal in various industries. This versatility is a key component that contributes to the significance and value of “r&j welding and metal fabrication“.

Metal’s unique properties, such as strength, durability, and malleability, make it an ideal material for a diverse range of applications. In the construction industry, metal is used to create structural frameworks, roofing systems, and architectural elements. Within the automotive industry, metal is essential for manufacturing vehicle chassis, engine components, and body panels. Other industries that rely heavily on “r&j welding and metal fabrication” include:

- Aerospace

- Shipbuilding

- Medical equipment

- Consumer electronics

- Art and sculpture

The versatility of “r&j welding and metal fabrication” offers numerous advantages:

- Adaptability to Diverse Needs: Metal can be customized to meet specific requirements, making it suitable for a wide range of projects and applications.

- Cost-Effectiveness: Metal fabrication allows for efficient production of complex shapes and components, reducing manufacturing costs.

- Sustainability: Metal is a durable and recyclable material, contributing to environmental sustainability.

Understanding the connection between versatility and “r&j welding and metal fabrication” is essential for several reasons:

- Appreciation of its Wide-Ranging Applications: It highlights the diverse industries and sectors that benefit from “r&j welding and metal fabrication“.

- Informed Decision-Making: It empowers individuals and businesses to make informed decisions about the use of metal in their projects.

- Innovation and Growth: It fosters innovation and growth within the metal fabrication industry, driving the development of new techniques and applications.

In conclusion, the versatility of “r&j welding and metal fabrication” is a key factor contributing to its significance and value. It allows metalworkers to create diverse and innovative solutions across a wide range of industries, meeting the evolving needs of the modern world.

| Industry | Metal Fabrication Applications | Examples |

|---|---|---|

| Construction | Structural frameworks, roofing systems, architectural elements | Skyscrapers, bridges, stadiums |

| Automotive | Vehicle chassis, engine components, body panels | Cars, trucks, motorcycles |

| Aerospace | Aircraft fuselages, wings, landing gear | Airplanes, helicopters, spacecraft |

| Medical Equipment | Surgical instruments, medical devices, prosthetics | Scalpels, MRI machines, artificial limbs |

| Art and Sculpture | Sculptures, decorative elements, architectural features | Public art installations, museum exhibits, custom furniture |

Customization

In the realm of “r&j welding and metal fabrication,” customization holds immense significance. It encompasses the ability to tailor metalwork to specific needs and designs, enabling the creation of unique and personalized solutions that cater to diverse requirements.

Customization in “r&j welding and metal fabrication” offers numerous advantages:

- Fulfilling Specific Needs: Customization allows metalworkers to meet unique requirements that may not be addressed by standardized products.

- Design Flexibility: It provides the freedom to explore innovative designs, pushing the boundaries of metalworking.

- Enhanced Functionality: Customized metal fabrications can be tailored to improve functionality and efficiency for specific applications.

The connection between customization and “r&j welding and metal fabrication” is evident in various real-life examples:

- Architectural Elements: Metalworkers create customized architectural elements, such as staircases, railings, and decorative panels, to enhance the aesthetic appeal and functionality of buildings.

- Industrial Machinery: Customized metal fabrications are used in industrial machinery to improve productivity and efficiency, catering to specific production requirements.

- Medical Equipment: Customization plays a crucial role in the fabrication of medical devices and prosthetics, ensuring they meet the unique needs of patients.

Understanding the connection between customization and “r&j welding and metal fabrication” is essential for several reasons:

- Appreciation of Craftsmanship: It highlights the skill and artistry involved in creating customized metalwork.

- Informed Decision-Making: It empowers individuals and businesses to make informed decisions about the customization of metal fabrications.

- Innovation and Growth: It drives innovation and growth within the metal fabrication industry, as metalworkers strive to meet the evolving needs of customers.

In conclusion, customization is an integral component of “r&j welding and metal fabrication,” allowing skilled metalworkers to create unique and tailored solutions that meet specific needs and designs. This understanding underscores the importance of customization in fulfilling diverse requirements, enhancing functionality, and driving innovation within the industry.

| Customization in “r&j welding and metal fabrication” | Benefits |

|---|---|

| Fulfilling Specific Needs | Meeting unique requirements not addressed by standardized products |

| Design Flexibility | Exploring innovative designs and pushing the boundaries of metalworking |

| Enhanced Functionality | Tailoring metal fabrications to improve functionality and efficiency for specific applications |

Safety

In the realm of “r&j welding and metal fabrication,” safety holds paramount importance. It encompasses adhering to industry standards and regulations to ensure the well-being of workers and the integrity of metal structures and products.

-

Compliance with Codes and Standards:

Metal fabricators must comply with established codes and standards, such as those set forth by the American Welding Society (AWS) and the Occupational Safety and Health Administration (OSHA). These standards provide guidelines for safe welding practices, proper handling of materials, and appropriate protective gear.

-

Risk Assessment and Mitigation:

Safety in “r&j welding and metal fabrication” involves conducting thorough risk assessments to identify potential hazards and implementing measures to mitigate those risks. This includes evaluating the work environment, materials being used, and potential sources of accidents.

-

Training and Certification:

Skilled metalworkers undergo rigorous training and certification programs to enhance their safety knowledge and proficiency. This ensures they possess the necessary skills to operate welding equipment safely, handle materials properly, and respond effectively to emergencies.

-

Personal Protective Equipment (PPE):

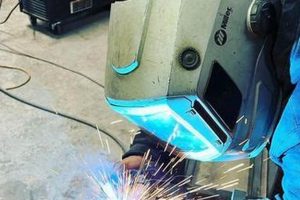

Wearing appropriate personal protective equipment (PPE) is crucial for the safety of metalworkers. This includes protective clothing, welding helmets, respirators, and gloves to shield them from sparks, fumes, and other hazards.

The connection between safety and “r&j welding and metal fabrication” is undeniable. By adhering to industry standards, conducting risk assessments, providing proper training, and ensuring the use of PPE, metal fabricators create a safe working environment and produce high-quality, reliable metal structures and products.

Innovation

In the realm of “r&j welding and metal fabrication,” innovation plays a pivotal role in driving progress and shaping the industry. It encompasses the continuous development of new techniques and applications, pushing the boundaries of what is possible with metal.

Innovation in “r&j welding and metal fabrication” manifests in various forms:

- Advanced Welding Techniques: Metal fabricators are constantly exploring and adopting new welding techniques, such as laser welding and friction stir welding, to enhance the precision, efficiency, and strength of welded joints.

- Novel Material Applications: Innovation extends to the development and utilization of novel materials, such as high-strength alloys and lightweight composites, expanding the range of applications for metal fabrications.

- Automated Fabrication Processes: The integration of automation and robotics in metal fabrication processes improves productivity, reduces costs, and enhances the consistency and quality of fabricated products.

- Sustainable Practices: Innovation also drives the adoption of sustainable practices in “r&j welding and metal fabrication,” such as the use of eco-friendly materials and energy-efficient processes, to minimize environmental impact.

The connection between innovation and “r&j welding and metal fabrication” is crucial for several reasons:

- Competitive Advantage: Continuous innovation enables metal fabricators to stay ahead of the competition by offering cutting-edge solutions and meeting evolving customer demands.

- Increased Efficiency: Innovative techniques and applications often lead to increased efficiency in fabrication processes, reducing production time and costs.

- Enhanced Product Quality: Innovation contributes to the development of higher-quality metal fabrications with improved strength, durability, and aesthetic appeal.

- Industry Growth and Development: Innovation drives the overall growth and development of the “r&j welding and metal fabrication” industry, fostering new opportunities and applications.

Understanding the connection between innovation and “r&j welding and metal fabrication” underscores the importance of investing in research and development, embracing new technologies, and fostering a culture of innovation within the industry. This enables metal fabricators to remain at the forefront of technological advancements and deliver exceptional products and services that meet the evolving needs of their customers.

| Innovation in “r&j welding and metal fabrication” | Benefits |

|---|---|

| Advanced Welding Techniques | Enhanced precision, efficiency, and strength of welded joints |

| Novel Material Applications | Expanded range of applications for metal fabrications |

| Automated Fabrication Processes | Improved productivity, reduced costs, and enhanced consistency |

| Sustainable Practices | Reduced environmental impact and promotion of sustainability |

In the realm of “r&j welding and metal fabrication,” collaboration is an indispensable aspect that fosters exceptional outcomes and strengthens the connection between metalworkers, clients, and other professionals.

- Effective Communication: Collaboration involves open and effective communication among metalworkers, clients, engineers, and architects. This ensures that project requirements, design specifications, and technical details are clearly understood and aligned, minimizing errors and ensuring a shared vision.

- Design Optimization: Through collaboration, metalworkers can actively participate in the design process, providing valuable insights based on their expertise in metal fabrication techniques and material properties. This collaborative approach often leads to optimized designs that are both aesthetically pleasing and structurally sound.

- Problem-Solving and Innovation: Collaboration fosters a collective problem-solving environment where diverse perspectives and expertise converge. By working together, metalworkers, engineers, and architects can explore innovative solutions, overcome challenges, and develop creative approaches to complex fabrication projects.

- Timely Project Execution: Collaborative planning and coordination among team members help streamline project execution. Clear communication, shared understanding, and efficient decision-making contribute to timely project completion, avoiding delays and ensuring that projects are delivered within the agreed-upon timeframe.

The interconnectedness of “Collaboration: Working closely with clients, engineers, and architects” and “r&j welding and metal fabrication” underscores the importance of teamwork, open communication, and shared expertise in achieving exceptional results. Collaboration fosters a dynamic and synergistic environment where the combined knowledge and skills of multiple professionals culminate in high-quality, innovative, and successful metal fabrication projects.

Sustainability

In the realm of “r&j welding and metal fabrication,” sustainability has emerged as a crucial consideration, driven by the growing awareness of environmental responsibility and the need to preserve natural resources. By embracing eco-friendly practices and materials, metal fabricators are not only reducing their environmental footprint but also creating durable and sustainable products that meet the demands of today’s eco-conscious consumers.

- Energy Efficiency: Metal fabricators are implementing energy-efficient practices throughout their operations, such as utilizing energy-saving equipment, optimizing lighting systems, and employing renewable energy sources. These measures reduce the carbon footprint of metal fabrication processes, contributing to a cleaner and greener environment.

- Material Selection: Sustainable metal fabrication involves the careful selection of materials with a focus on their environmental impact. Recycled metals, for instance, offer a viable alternative to virgin materials, reducing the need for mining and extraction. Additionally, metal fabricators are exploring the use of sustainable materials, such as bamboo and bioplastics, to further minimize their ecological impact.

- Waste Reduction: Waste reduction is a key aspect of sustainable metal fabrication. Metal fabricators are implementing innovative techniques to minimize waste generation, such as optimizing cutting patterns and utilizing scrap metal for other applications. By reducing waste, metal fabricators not only conserve resources but also reduce the amount of waste going to landfills.

- Environmental Compliance: Adhering to environmental regulations and standards is essential for sustainable metal fabrication. Metal fabricators are required to comply with regulations governing air emissions, wastewater discharge, and hazardous waste disposal. By meeting these requirements, metal fabricators demonstrate their commitment to environmental protection and responsible manufacturing practices.

The connection between “Sustainability: Using eco-friendly practices and materials” and “r&j welding and metal fabrication” underscores the growing importance of environmental responsibility in the metal fabrication industry. By embracing sustainability, metal fabricators are not only creating durable and high-quality products but also contributing to a more sustainable future. As consumers become increasingly environmentally conscious, sustainable metal fabrication practices will become even more critical for businesses looking to maintain a competitive edge.

Frequently Asked Questions

This section addresses common questions and concerns related to “r&j welding and metal fabrication” to provide comprehensive information and dispel any misconceptions.

Question 1: What sets “r&j welding and metal fabrication” apart from other fabrication companies?

Answer: “r&j welding and metal fabrication” distinguishes itself through its unwavering commitment to quality, precision, and innovation. Our team of highly skilled metalworkers possesses extensive expertise in various welding and fabrication techniques, ensuring the highest standards of craftsmanship. Moreover, we prioritize customer satisfaction by actively listening to our clients’ needs and tailoring our services to meet their unique requirements.

Question 2: How does “r&j welding and metal fabrication” guarantee the quality of its products?

Answer: Quality is paramount at “r&j welding and metal fabrication“. We adhere to rigorous quality control measures throughout our fabrication processes, from material selection to final inspection. Our team utilizes advanced technology and industry-leading practices to ensure that every product meets our exacting standards. Additionally, we provide comprehensive documentation and certifications to assure our clients of the quality and integrity of our work.

Question 3: What types of metal fabrication services does “r&j welding and metal fabrication” offer?

Answer: “r&j welding and metal fabrication” offers a comprehensive range of metal fabrication services to cater to diverse client needs. Our services encompass custom fabrication, structural steel fabrication, architectural metalwork, ornamental ironwork, and specialized welding services. We possess the expertise and equipment to handle projects of varying complexity and scale.

Question 4: Can “r&j welding and metal fabrication” handle large-scale fabrication projects?

Answer: Absolutely. “r&j welding and metal fabrication” is well-equipped and experienced in undertaking large-scale fabrication projects. Our team has successfully completed numerous complex and demanding projects, including the fabrication and installation of structural steel frameworks for commercial buildings, bridges, and industrial facilities.

Question 5: How does “r&j welding and metal fabrication” ensure timely project completion?

Answer: Timeliness is crucial at “r&j welding and metal fabrication“. We understand the importance of meeting project deadlines and work diligently to ensure timely completion. Our team employs efficient project management techniques, maintains open communication with clients, and optimizes our fabrication processes to deliver projects within the agreed-upon timelines.

Question 6: What safety measures does “r&j welding and metal fabrication” have in place?

Answer: Safety is a top priority at “r&j welding and metal fabrication“. We strictly adhere to industry-leading safety standards and regulations. Our team undergoes comprehensive safety training and is equipped with the necessary personal protective equipment. We maintain a clean and organized work environment and regularly conduct safety inspections to minimize risks and ensure the well-being of our employees and clients.

Summary: “r&j welding and metal fabrication” is committed to providing exceptional metal fabrication services that meet the highest standards of quality, precision, and innovation. Our team of skilled professionals, combined with our commitment to customer satisfaction, ensures that every project we undertake is executed with the utmost care and expertise.

Transition: To delve deeper into the world of metal fabrication and explore its diverse applications, proceed to the next section where we unravel the intricate details of this fascinating field.

Tips from “r&j welding and metal fabrication”

In the realm of metal fabrication, expertise and precision are paramount. To assist you in your fabrication endeavors, “r&j welding and metal fabrication” offers the following invaluable tips:

Tip 1: Choose the Right Materials: Selecting the appropriate metal for your project is crucial. Consider factors such as strength, durability, corrosion resistance, and weldability. Seek advice from experienced metal fabricators to ensure optimal material selection.

Tip 2: Utilize Proper Welding Techniques: Master the art of welding to create strong and reliable joints. Familiarize yourself with different welding methods, including MIG, TIG, and stick welding. Practice on scrap metal to refine your skills before tackling actual projects.

Tip 3: Invest in Quality Equipment: Equip yourself with high-quality welding and fabrication tools. This investment will enhance your precision, efficiency, and overall productivity. Regularly maintain your equipment to ensure optimal performance.

Tip 4: Prioritize Safety: Safety should be your utmost priority in any metal fabrication project. Wear appropriate protective gear, including welding helmets, gloves, and fire-resistant clothing. Ensure proper ventilation in your workspace to avoid inhaling harmful fumes.

Tip 5: Seek Professional Advice: If you encounter complex fabrication challenges, do not hesitate to consult experienced metal fabricators. Their expertise can guide you towards effective solutions and prevent costly mistakes.

Tip 6: Practice Patience and Precision: Metal fabrication is an art that requires patience and meticulous attention to detail. Take your time to plan and execute each step with precision. Avoid rushing the process, as haste can compromise the quality of your work.

Tip 7: Continuous Learning: Stay abreast of the latest advancements in metal fabrication techniques and technologies. Attend workshops, read industry publications, and connect with fellow fabricators to expand your knowledge and skills.

Summary: By adhering to these tips from “r&j welding and metal fabrication,” you can elevate your fabrication projects to new heights. Remember, quality, precision, and safety should always be at the forefront of your endeavors.

Transition: As you embark on your metal fabrication journey, let the insights provided by these tips serve as your guiding light. Embrace the challenges, learn from your experiences, and continuously strive for excellence in this rewarding field.

Conclusion

Through this comprehensive exploration of “r&j welding and metal fabrication,” we have illuminated the multifaceted nature of this remarkable field. From the intricate craftsmanship to the innovative applications, metal fabrication stands as a testament to human ingenuity and the boundless possibilities of metal.

As we look towards the future, the significance of “r&j welding and metal fabrication” will only continue to grow. With the increasing demand for sustainable and durable solutions, metal fabricators will play a pivotal role in shaping our built environment and advancing technological frontiers. By embracing innovation, collaboration, and a commitment to excellence, the future of “r&j welding and metal fabrication” is poised for continued success.