What is South Coast Welding and Fabrication?

_Editor’s Note: South coast welding and fabrication is a metalworking process that joins materials, usually metals, by causing fusion.

Our team has analyzed the south coast welding and fabrication industry and compiled this guide to help you make informed decisions about your welding and fabrication needs.

_Key Differences_

| Feature | South Coast Welding and Fabrication ||—|—|| Process | Joining materials by causing fusion || Materials | Usually metals || Applications | Wide range of industries, including automotive, construction, and manufacturing |

Main Article Topics

Benefits of South Coast Welding and Fabrication Applications of South Coast Welding and Fabrication How to Choose a South Coast Welding and Fabrication Company The Future of South Coast Welding and Fabrication

South Coast Welding and Fabrication

South coast welding and fabrication encompasses a wide range of essential aspects that contribute to its significance in various industries. These key aspects include:

- Materials: Metals, plastics, composites

- Processes: Welding, cutting, forming

- Equipment: Welders, cutters, presses

- Industries: Automotive, construction, manufacturing

- Applications: Joining, repairing, fabricating

- Quality: Precision, durability

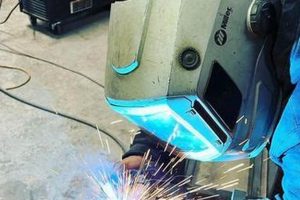

- Safety: Protective gear, training

- Sustainability: Eco-friendly practices

- Innovation: New technologies, techniques

- Careers: Welders, fabricators, engineers

- Economic impact: Job creation, infrastructure development

These aspects are interconnected and play a crucial role in the success of south coast welding and fabrication projects. For instance, using high-quality materials and equipment ensures durability and precision in the finished product. Skilled workers and adherence to safety standards promote a safe and efficient work environment. Furthermore, innovation in welding and fabrication techniques leads to improved productivity and cost-effectiveness. Understanding these key aspects provides a comprehensive insight into the field of south coast welding and fabrication and its relevance to modern industries.

Materials: Metals, Plastics, Composites

The materials used in south coast welding and fabrication play a critical role in determining the properties, performance, and applications of the finished product. The three main categories of materials used are:

- Metals: Metals are the most common materials used in welding and fabrication, owing to their strength, durability, and weldability. Common metals used include steel, aluminum, and stainless steel, each with its unique characteristics and applications.

- Plastics: Plastics are lightweight, corrosion-resistant, and offer a wide range of properties, making them suitable for various applications. Common plastics used in welding and fabrication include PVC, polyethylene, and polypropylene.

- Composites: Composites are combinations of two or more materials, typically a reinforcing material (such as fiberglass or carbon fiber) and a matrix material (such as plastic or metal). Composites offer high strength-to-weight ratios and can be tailored to specific requirements.

The choice of materials in south coast welding and fabrication depends on several factors, including the intended application, required strength, durability, corrosion resistance, and cost. By carefully selecting and combining materials, manufacturers can create products that meet the specific demands of their customers.

Processes: Welding, Cutting, Forming

In the realm of south coast welding and fabrication, three fundamental processes take center stage: welding, cutting, and forming. These processes are the building blocks of countless products and structures that shape our world.

-

Welding

Welding is the process of joining materials, usually metals, by causing fusion. This is achieved by applying intense heat to the materials, causing them to melt and fuse together. Welding is used in a wide range of applications, from construction to manufacturing to art. -

Cutting

Cutting is the process of separating materials, usually metals, by applying a cutting tool. This can be done using a variety of methods, including sawing, shearing, and laser cutting. Cutting is used in a wide range of applications, from metalworking to construction to recycling. -

Forming

Forming is the process of changing the shape of materials, usually metals, by applying force. This can be done using a variety of methods, including bending, rolling, and forging. Forming is used in a wide range of applications, from automotive manufacturing to aerospace to shipbuilding.

These three processes are essential to south coast welding and fabrication. They allow manufacturers to create complex and durable products from a variety of materials. By understanding these processes, we can better appreciate the skill and craftsmanship that goes into every welded, cut, and formed product.

Equipment: Welders, Cutters, Presses

In the realm of south coast welding and fabrication, the equipment employed plays a pivotal role in determining the quality, efficiency, and safety of the . Three essential types of equipment stand out: welders, cutters, and presses.

Welders are the workhorses of the welding process. They generate intense heat, enabling the fusion of materials and the creation of strong, durable joints. From arc welders to MIG welders to TIG welders, each type of welder is suited to specific welding applications.

Cutters, on the other hand, are responsible for separating materials with precision. Whether it’s a plasma cutter, a laser cutter, or a water jet cutter, these tools employ various technologies to cut through metals and other materials with accuracy and efficiency.

Presses, with their immense force, are used to shape and form materials. They can bend, fold, or stamp metal sheets into complex shapes, creating components for a wide range of industries.

The interplay between these three types of equipment is essential to south coast welding and fabrication. Welders join materials, cutters separate them, and presses shape them. Together, they enable the creation of countless products and structures that we rely on in our daily lives.

| Equipment | Function | Applications |

|---|---|---|

| Welders | Joining materials by fusion | Construction, manufacturing, automotive |

| Cutters | Separating materials with precision | Metalworking, construction, recycling |

| Presses | Shaping and forming materials | Automotive manufacturing, aerospace, shipbuilding |

Industries: Automotive, construction, manufacturing

South coast welding and fabrication play a pivotal role in three major industries: automotive, construction, and manufacturing. These industries rely on welding and fabrication techniques to create a wide range of products and structures.

- Automotive: Welding is essential in the automotive industry for joining metal components in vehicles, such as car bodies, frames, and exhaust systems. Fabrication techniques are used to create custom parts and accessories, as well as to repair damaged vehicles.

- Construction: Welding and fabrication are crucial in the construction industry for erecting buildings, bridges, and other structures. Steel beams, metal panels, and piping systems are all joined together using welding techniques. Fabrication is also used to create custom architectural elements, such as railings, staircases, and decorative pieces.

- Manufacturing: Welding and fabrication are essential in the manufacturing industry for creating a wide range of products, including machinery, appliances, and consumer goods. Metal components are joined together using welding techniques, and fabrication is used to shape and form metal into desired shapes and sizes.

The connection between south coast welding and fabrication and these three industries is undeniable. Welding and fabrication techniques are essential for creating the products and structures that we rely on in our daily lives. From the cars we drive to the buildings we live in to the products we use, welding and fabrication play a vital role in our modern world.

Applications: Joining, repairing, fabricating

The applications of south coast welding and fabrication extend far and wide, encompassing a diverse range of industries and purposes. From joining components to repairing damaged structures to fabricating custom creations, welding and fabrication techniques play a vital role in shaping our world.

- Joining: Welding is the primary method used to join metal components, creating strong and durable bonds. In the automotive industry, welding is essential for assembling car bodies, frames, and exhaust systems. In construction, welding is used to connect steel beams, metal panels, and piping systems in buildings and bridges.

- Repairing: Welding is also widely used to repair damaged metal structures. Whether it’s a cracked pipe, a broken machine part, or a damaged car body, welding can restore the integrity and functionality of the affected component.

- Fabricating: Fabrication involves shaping and forming metal into desired shapes and sizes. This process is essential for creating custom parts, components, and structures. From intricate architectural elements to heavy machinery, fabrication techniques enable the creation of unique and specialized products.

The applications of south coast welding and fabrication are vast and varied, touching upon almost every aspect of our modern world. From the cars we drive to the buildings we live in to the products we use, welding and fabrication play a vital role in our daily lives.

Quality: Precision, durability

In the realm of south coast welding and fabrication, quality is paramount. Precision and durability are two essential components that underpin the success and reputation of any welding and fabrication company. Precision refers to the accuracy and exactness with which a welding or fabrication job is executed, while durability refers to the ability of the finished product to withstand wear and tear over time.

Achieving precision in south coast welding and fabrication requires skilled craftspeople who are meticulous in their work. Welders must have a steady hand and a keen eye to ensure that welds are clean, consistent, and meet the required specifications. Fabricators must be equally precise in their measurements and cutting techniques to ensure that components fit together perfectly and function as intended.

Durability is another critical aspect of quality in south coast welding and fabrication. Welds and fabricated components must be able to withstand the rigors of their intended use, whether it’s a structural beam in a high-rise building or a component in a heavy-duty machine. To achieve durability, welders and fabricators must use high-quality materials and follow best practices in welding and fabrication techniques.

The connection between quality, precision, and durability in south coast welding and fabrication cannot be overstated. By prioritizing these aspects, welding and fabrication companies can produce products that are not only aesthetically pleasing but also safe, reliable, and long-lasting.

| Quality Aspect | Description | Importance |

|---|---|---|

| Precision | Accuracy and exactness in welding and fabrication | Ensures structural integrity, functionality, and aesthetics |

| Durability | Ability to withstand wear and tear over time | Ensures safety, reliability, and longevity of welded and fabricated products |

Safety: Protective Gear, Training

In the realm of south coast welding and fabrication, safety is of utmost importance. The use of protective gear and proper training are essential components to ensure the well-being of workers and the prevention of accidents.

-

Protective Gear:

Welders and fabricators are exposed to various hazards during their work, including intense heat, sparks, fumes, and sharp edges. Protective gear, such as welding helmets, gloves, and flame-resistant clothing, is essential to safeguard workers from these hazards. Helmets protect the eyes and face from harmful radiation and sparks, while gloves prevent burns and other injuries to the hands. Flame-resistant clothing reduces the risk of burns in the event of an accident.

-

Training:

Proper training is crucial for workers to understand the safety procedures and best practices in south coast welding and fabrication. This includes training on the proper use of equipment, handling of materials, and emergency response procedures. Well-trained workers are more likely to identify and avoid hazards, reducing the risk of accidents and injuries.

-

Workplace Safety:

In addition to personal protective gear and training, maintaining a safe workplace is essential. This includes proper ventilation to remove harmful fumes, adequate lighting to enhance visibility, and clear walkways to prevent tripping hazards. Regular maintenance of equipment and adherence to safety protocols further contribute to a safe working environment.

By prioritizing safety through the use of protective gear, training, and workplace safety measures, south coast welding and fabrication companies can create a work environment that protects their employees and minimizes the risk of accidents and injuries.

Sustainability: Eco-friendly practices

In the realm of south coast welding and fabrication, sustainability and eco-friendly practices are gaining increasing recognition as essential components of responsible manufacturing. The integration of sustainable practices not only benefits the environment but also aligns with the growing demand for environmentally conscious products and services.

One of the key aspects of sustainability in south coast welding and fabrication is the reduction of waste and emissions. By adopting eco-friendly practices, such as using recycled materials and implementing energy-efficient processes, welding and fabrication companies can minimize their environmental footprint. This includes reducing the use of hazardous chemicals, optimizing cutting and welding techniques to minimize material waste, and implementing proper waste management systems.

Another important aspect of sustainability is the use of renewable energy sources. By incorporating solar or wind energy into their operations, south coast welding and fabrication companies can reduce their reliance on fossil fuels and contribute to a cleaner environment. Additionally, sustainable practices extend to the use of sustainable materials, such as recycled metals and eco-friendly coatings, which further reduce the environmental impact of welding and fabrication processes.

The practical significance of sustainability in south coast welding and fabrication is reflected in the growing demand for sustainable products and services. Consumers and businesses are increasingly seeking out companies that prioritize environmental responsibility. By embracing sustainability, welding and fabrication companies can not only reduce their environmental impact but also gain a competitive edge in the marketplace.

| Sustainability Practice | Benefits |

|---|---|

| Use of recycled materials | Reduces waste and conserves natural resources |

| Energy-efficient processes | Reduces greenhouse gas emissions |

| Use of renewable energy sources | Reduces reliance on fossil fuels |

| Use of sustainable materials | Reduces environmental impact |

In conclusion, the connection between sustainability and south coast welding and fabrication is becoming increasingly important. By adopting eco-friendly practices, welding and fabrication companies can reduce their environmental impact, meet growing customer demands for sustainable products and services, and contribute to a more sustainable future.

Innovation: New technologies, techniques

In the ever-evolving realm of south coast welding and fabrication, innovation plays a pivotal role in driving progress and shaping the industry’s future. The adoption of new technologies and cutting-edge techniques has revolutionized the way welding and fabrication are performed, leading to increased efficiency, precision, and versatility.

One of the most significant innovations in south coast welding and fabrication is the advent of robotic welding. Robotic welding systems utilize computer-controlled robots to perform welding tasks with unmatched accuracy and speed. This technology has not only improved the consistency and quality of welds but has also enabled the automation of complex welding processes, reducing labor costs and increasing productivity.

Another notable innovation is the development of advanced welding techniques, such as laser welding and electron beam welding. These techniques offer unparalleled precision and control, allowing for the welding of delicate materials and intricate components. Laser welding, in particular, has gained popularity in industries such as aerospace and medical device manufacturing, where precision and reliability are paramount.

The practical significance of innovation in south coast welding and fabrication extends far beyond technological advancements. New technologies and techniques have transformed the industry, enabling the production of lighter, stronger, and more durable products. These innovations have also opened up new possibilities for design and engineering, allowing manufacturers to create products that were previously impossible to fabricate.

| Innovation | Benefits |

|---|---|

| Robotic welding | Increased efficiency, precision, and versatility |

| Advanced welding techniques (laser welding, electron beam welding) | Unparalleled precision and control |

| New materials and alloys | Lighter, stronger, and more durable products |

In conclusion, the connection between innovation and south coast welding and fabrication is inseparable. The adoption of new technologies and techniques has driven the industry forward, enabling the production of high-quality products, increasing efficiency, and opening up new possibilities for design and engineering. As the industry continues to evolve, innovation will undoubtedly remain at the forefront, shaping the future of south coast welding and fabrication.

Careers: Welders, fabricators, engineers

Within the realm of south coast welding and fabrication, a diverse range of professionals play critical roles, each contributing their unique skills and expertise to the success of the industry. These professionals include welders, fabricators, and engineers, whose interconnected roles drive innovation, precision, and quality in the field.

-

Welders

Welders are the backbone of south coast welding and fabrication, responsible for joining materials using specialized welding techniques. They possess a keen eye for detail and a steady hand, ensuring that welds meet precise specifications and quality standards. Welders work in various industries, including construction, automotive, and manufacturing, contributing to the creation of everything from buildings and bridges to vehicles and machinery. -

Fabricators

Fabricators transform raw materials into complex shapes and components through cutting, bending, and forming techniques. They utilize a range of tools and equipment, including CNC machines and welding equipment, to create custom parts and structures. Fabricators play a vital role in industries such as aerospace, shipbuilding, and metalworking, where precision and attention to detail are paramount. -

Engineers

Engineers design and develop the plans and specifications that guide the welding and fabrication processes. They work closely with welders and fabricators to ensure that projects meet functional and safety requirements. Engineers also conduct research and development to improve welding and fabrication techniques, materials, and equipment.

The connection between these careers and south coast welding and fabrication is evident in the collaborative nature of the work. Welders, fabricators, and engineers rely on each other’s expertise to deliver high-quality products and structures. By combining their skills and knowledge, they create solutions that are both functional and aesthetically pleasing, contributing to the success and reputation of the south coast welding and fabrication industry.

Economic impact: Job creation, infrastructure development

The connection between ” Economic impact: Job creation, infrastructure development” and “south coast welding and fabrication” lies in the vital role the industry plays in driving economic growth and progress. South coast welding and fabrication contribute significantly to these aspects through various mechanisms:

Job creation: The welding and fabrication industry generates numerous employment opportunities for skilled workers. Welders, fabricators, engineers, and other professionals are in high demand, as their skills are essential for the construction, maintenance, and repair of various structures and products. By providing stable and well-paying jobs, south coast welding and fabrication contribute to the economic well-being of individuals, families, and communities.

Infrastructure development: Welding and fabrication are indispensable in the development and maintenance of infrastructure, which forms the backbone of modern society. From bridges and buildings to pipelines and power plants, south coast welding and fabrication play a crucial role in creating and sustaining the infrastructure that supports economic activities and improves the quality of life. By ensuring the safety and reliability of infrastructure, the industry contributes to economic growth and stability.

The practical significance of understanding this connection lies in recognizing the importance of investing in and supporting the south coast welding and fabrication industry. By providing training programs, promoting innovation, and encouraging investment in this sector, governments and policymakers can harness its potential to drive economic development and improve the overall well-being of society.

FAQs on South Coast Welding and Fabrication

This section addresses frequently asked questions related to south coast welding and fabrication, providing concise and informative answers to clarify common concerns and misconceptions.

Question 1: What is the difference between welding and fabrication?

Answer: Welding is a process that joins materials, usually metals, by causing fusion. Fabrication, on the other hand, encompasses a broader range of processes used to shape and assemble materials, including welding, cutting, bending, and forming.

Question 2: What materials can be welded and fabricated?

Answer: South coast welding and fabrication can be performed on a wide variety of materials, including metals (such as steel, aluminum, and stainless steel), plastics, and composites. The choice of material depends on the specific application and desired properties.

Question 3: What are the applications of south coast welding and fabrication?

Answer: South coast welding and fabrication find applications in numerous industries, including construction, automotive, manufacturing, and shipbuilding. They are used to create a vast array of products and structures, from bridges and buildings to vehicles and machinery.

Question 4: What safety precautions should be taken during welding and fabrication?

Answer: Safety is paramount in south coast welding and fabrication. Proper protective gear, including welding helmets, gloves, and flame-resistant clothing, is essential to safeguard against hazards such as intense heat, sparks, and fumes. Adequate ventilation and adherence to safety protocols are also crucial.

Question 5: What are the career opportunities in south coast welding and fabrication?

Answer: The industry offers diverse career paths for skilled professionals, including welders, fabricators, engineers, and inspectors. These professionals play vital roles in design, production, and quality control, contributing to the success and reputation of south coast welding and fabrication.

Question 6: How can I learn more about south coast welding and fabrication?

Answer: There are various resources available to gain knowledge and skills in south coast welding and fabrication. Technical schools, community colleges, and industry workshops offer training programs and courses. Additionally, industry associations and online resources provide valuable information and support.

These FAQs provide a foundational understanding of key aspects related to south coast welding and fabrication. For further exploration, the following article sections offer in-depth insights into the processes, applications, and significance of this industry.

Transition to the next article section: Discover the diverse applications of south coast welding and fabrication across various industries.

Tips for South Coast Welding and Fabrication

South coast welding and fabrication involve complex processes and techniques that require precision, safety, and efficiency. Here are some essential tips to optimize your welding and fabrication practices:

Tip 1: Choose the Right Materials

Selecting the appropriate materials for your welding and fabrication project is crucial. Consider factors such as the intended application, required strength, durability, and cost. Common materials used include steel, aluminum, stainless steel, and various plastics.

Tip 2: Utilize Proper Welding Techniques

Mastering the correct welding technique is essential for achieving strong and durable welds. Choose the appropriate welding process (e.g., MIG, TIG, arc welding) based on the materials and project requirements. Ensure proper joint preparation, electrode selection, and welding parameters to optimize weld quality.

Tip 3: Ensure Workplace Safety

Safety should be a top priority in any welding and fabrication environment. Wear appropriate protective gear, including a welding helmet, gloves, and flame-resistant clothing. Maintain a clean and well-ventilated workspace to minimize exposure to fumes and hazards.

Tip 4: Invest in Quality Equipment

Investing in high-quality welding and fabrication equipment is essential for efficient and precise work. Choose reliable welding machines, cutting tools, and safety gear that meet industry standards. Regular maintenance and calibration of equipment ensure optimal performance and safety.

Tip 5: Seek Professional Training

Consider enrolling in professional training programs or workshops to enhance your welding and fabrication skills. This provides structured learning, hands-on practice, and certification to validate your proficiency.

Tip 6: Stay Updated with Industry Advancements

The welding and fabrication industry is constantly evolving with new technologies and techniques. Attend industry events, read technical literature, and engage with professionals to stay informed about the latest advancements and best practices.

Tip 7: Practice Regularly

Regular practice is key to mastering welding and fabrication techniques. Dedicate time to practicing on scrap materials or small projects to improve your skills, consistency, and confidence.

Tip 8: Collaborate with Experts

For complex projects or specialized applications, consider collaborating with experienced welders, fabricators, or engineers. Their expertise can provide valuable insights, problem-solving, and quality assurance.

These tips, when followed diligently, can significantly enhance the quality, safety, and efficiency of your south coast welding and fabrication projects.

Transition to the article’s conclusion: By embracing these tips, you can elevate your welding and fabrication skills, ensuring the successful execution of your projects.

Conclusion

South coast welding and fabrication are essential processes that shape our world, from towering skyscrapers to intricate medical devices. This article has explored the multifaceted nature of this industry, highlighting its applications, processes, and significance in various sectors.

The connection between south coast welding and fabrication and industries like construction, automotive, and manufacturing is undeniable. These processes are pivotal in creating durable structures, reliable vehicles, and functional machinery. Moreover, south coast welding and fabrication play a crucial role in innovation, enabling the development of new technologies and sustainable solutions.

As we look toward the future, south coast welding and fabrication will continue to drive progress and shape our built environment. By embracing innovation, prioritizing safety, and investing in skilled professionals, we can harness the full potential of this industry to create a better and more sustainable tomorrow.