Steel Fabrication Companies in Australiaare in high demand due to the country’s rapidly growing construction industry. These companies specialize in the fabrication and installation of structural steel components for a wide range of projects, from small residential buildings to large commercial and industrial structures.

Editor’s Note:Steel fabrication is a critical component of modern construction, and choosing the right company for your project is essential. To help you make an informed decision, we’ve put together this guide to the top steel fabrication companies in Australia.

We’ve done the research, dug through the data, and talked to industry experts to put together this comprehensive guide to steel fabrication companies in Australia. Whether you’re looking for a company to fabricate and install structural steel for a new building or you need a company to repair or replace existing steelwork, we’ve got you covered.

Key Differences:

| Factor | Description |

|---|---|

| Experience | The number of years a company has been in business and the types of projects they have completed. |

| Expertise | The types of steel fabrication and installation services a company offers. |

| Capacity | The size and capabilities of a company’s fabrication and installation facilities. |

| Cost | The price of a company’s services. |

Transition to main article topics:

- The benefits of using a steel fabrication company

- The different types of steel fabrication services

- How to choose the right steel fabrication company

- Profiles of the top steel fabrication companies in Australia

Steel Fabrication Companies in Australia

Steel fabrication companies in Australia play a vital role in the construction industry, providing essential services for a wide range of projects. Here are 12 key aspects to consider when choosing a steel fabrication company in Australia:

- Experience: The number of years a company has been in business and the types of projects they have completed.

- Expertise: The types of steel fabrication and installation services a company offers.

- Capacity: The size and capabilities of a company’s fabrication and installation facilities.

- Cost: The price of a company’s services.

- Quality: The quality of a company’s workmanship and materials.

- Safety: A company’s safety record and commitment to workplace safety.

- Customer service: The level of customer service a company provides.

- Location: The location of a company’s facilities in relation to your project site.

- Insurance: The types of insurance a company carries.

- Certifications: The certifications a company holds.

- Reputation: The reputation of a company in the industry.

- Sustainability: A company’s commitment to sustainability and environmental responsibility.

These key aspects are all important to consider when choosing a steel fabrication company in Australia. By carefully considering each of these factors, you can choose a company that is best suited to your needs and project requirements.

For example, if you are working on a large commercial project, you will need to choose a company with a proven track record of success on similar projects. You will also need to consider the company’s capacity to handle the size and complexity of your project. If you are working on a smaller project, you may be able to choose a company with less experience, but you will still need to make sure that the company is qualified and insured.

No matter what size or type of project you are working on, it is important to choose a steel fabrication company that you can trust. By taking the time to consider the key aspects outlined above, you can choose a company that will provide you with the high-quality products and services you need.

Experience

When choosing a steel fabrication company in Australia, it is important to consider the company’s experience. This includes the number of years the company has been in business and the types of projects they have completed. A company with a long history of success in the industry is more likely to have the skills and expertise to complete your project on time and within budget.

-

Facet 1: Years of Experience

The number of years a company has been in business is a good indicator of their experience and expertise. A company that has been in business for many years has had the opportunity to develop a strong track record of success. They are also more likely to have a team of experienced engineers and fabricators who are familiar with the latest industry trends and technologies.

-

Facet 2: Types of Projects

The types of projects a company has completed can also give you valuable insights into their experience and capabilities. If you are working on a large commercial project, you will want to choose a company that has experience with similar projects. This will ensure that the company has the skills and expertise to complete your project on time and within budget.

-

Facet 3: Client Testimonials

Client testimonials can also be a helpful way to assess a company’s experience. Positive testimonials from past clients indicate that the company is reliable, trustworthy, and produces high-quality work.

-

Facet 4: Industry Awards

Industry awards are another indication of a company’s experience and expertise. Companies that have won industry awards are recognized for their high-quality work, customer service, and innovation.

By considering the experience of a steel fabrication company, you can choose a company that is qualified and capable of completing your project on time and within budget.

Expertise

The types of steel fabrication and installation services a company offers can vary greatly. Some companies specialize in a particular type of fabrication, such as structural steel or architectural steel. Others offer a wider range of services, including design, engineering, fabrication, and installation. When choosing a steel fabrication company in Australia, it is important to consider the types of services you need.

If you are working on a large commercial project, you will need to choose a company that offers a full range of services, from design to installation. This will ensure that the company has the expertise and capabilities to complete your project on time and within budget.

If you are working on a smaller project, you may be able to choose a company that specializes in a particular type of fabrication. This can save you money and time. However, it is important to make sure that the company you choose has the experience and expertise to complete your project to a high standard.

Here are some of the most common types of steel fabrication and installation services offered by companies in Australia:

- Structural steel fabrication and installation: This includes the fabrication and installation of structural steel beams, columns, and girders. Structural steel is used to support the weight of a building or other structure.

- Architectural steel fabrication and installation: This includes the fabrication and installation of architectural steel elements, such as stairs, railings, and facades. Architectural steel is used to enhance the aesthetic appeal of a building or other structure.

- Plate steel fabrication and installation: This includes the fabrication and installation of plate steel components, such as tanks, vessels, and pressure vessels. Plate steel is used in a variety of applications, including the storage and transportation of liquids and gases.

- Pipe steel fabrication and installation: This includes the fabrication and installation of pipe steel components, such as pipelines, manifolds, and fittings. Pipe steel is used to transport liquids and gases in a variety of applications, including the oil and gas industry.

By understanding the different types of steel fabrication and installation services offered by companies in Australia, you can choose a company that has the expertise and capabilities to complete your project on time and within budget.

Capacity

When choosing a steel fabrication company in Australia, it is important to consider the company’s capacity. This includes the size and capabilities of the company’s fabrication and installation facilities. A company with a large, well-equipped facility is more likely to be able to handle large and complex projects. They are also more likely to have the capacity to meet tight deadlines.

-

Size of the facility

The size of a company’s fabrication and installation facility is an important factor to consider. A larger facility will have more space for equipment and workers, which can lead to faster turnaround times. A larger facility is also more likely to have the capacity to handle large and complex projects. -

Capabilities of the equipment

The capabilities of a company’s equipment is another important factor to consider. Some companies have state-of-the-art equipment that can handle a wide range of fabrication tasks. Other companies have more basic equipment that is only suitable for simple tasks. When choosing a steel fabrication company, it is important to make sure that the company has the equipment to handle your specific project requirements. -

Number of employees

The number of employees a company has can also be an indicator of its capacity. A company with a large number of employees is more likely to be able to handle large and complex projects. They are also more likely to have the capacity to meet tight deadlines. -

Location of the facility

The location of a company’s fabrication and installation facility is also an important factor to consider. A company that is located close to your project site will be able to deliver and install your steel components more quickly and efficiently. This can save you time and money.

By considering the capacity of a steel fabrication company, you can choose a company that has the size, capabilities, and resources to complete your project on time and within budget.

Cost

The cost of a steel fabrication company’s services is an important factor to consider when choosing a company. The cost of steel fabrication services can vary depending on a number of factors, including the size and complexity of the project, the type of steel being used, and the location of the project. It is important to get quotes from several different companies before making a decision.

The cost of steel fabrication services is often a major factor in the overall cost of a construction project. For example, the cost of steel fabrication services can account for up to 20% of the total cost of a commercial building project. As a result, it is important to choose a steel fabrication company that offers competitive pricing.

In addition to the cost of the fabrication services themselves, it is also important to consider the cost of delivery and installation. The cost of delivery and installation can vary depending on the location of the project and the size and weight of the steel components.

By understanding the cost of steel fabrication services, you can make informed decisions about your project budget. Here are some tips for saving money on steel fabrication services:

- Get quotes from several different companies before making a decision.

- Negotiate the price of the services.

- Consider using a less expensive type of steel.

- Choose a steel fabrication company that is located close to your project site.

By following these tips, you can save money on steel fabrication services without sacrificing quality.

Table: Cost of steel fabrication services

| Type of steel | Cost per tonne |

|---|---|

| Mild steel | $500-$700 |

| Stainless steel | $1,000-$1,500 |

| Aluminum | $1,500-$2,000 |

Quality

Quality is one of the most important factors to consider when choosing a steel fabrication company in Australia. The quality of a company’s workmanship and materials will directly impact the safety, durability, and appearance of your finished product.

-

Facet 1: Workmanship

The quality of a company’s workmanship refers to the skill and care with which they fabricate steel components. Good workmanship is essential for ensuring that steel components are fabricated to the correct specifications and that they are safe and durable.

-

Facet 2: Materials

The quality of a company’s materials refers to the type and grade of steel that they use. Different types of steel have different properties, so it is important to choose a steel that is suitable for your specific application. A reputable steel fabrication company will be able to advise you on the best type of steel to use for your project.

-

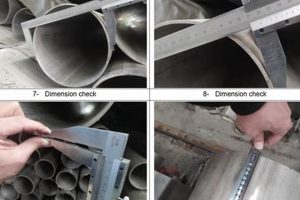

Facet 3: Quality Control

A company’s quality control procedures are essential for ensuring that their products meet the highest standards. A good quality control program will include regular inspections of raw materials, work in progress, and finished products. It will also include procedures for correcting any defects that are found.

-

Facet 4: Certifications

There are a number of industry certifications that can provide assurance of a company’s quality. For example, the ISO 9001 certification is an international standard that sets out the requirements for a quality management system. A company that is ISO 9001 certified has demonstrated that they have a robust quality management system in place.

By considering the quality of a company’s workmanship, materials, quality control procedures, and certifications, you can choose a steel fabrication company that will provide you with high-quality products that meet your specific needs.

Safety

In the steel fabrication industry, safety is of paramount importance. Steel fabrication processes involve the use of heavy machinery and hazardous materials, making it essential for companies to prioritize the safety of their employees and the community. A company’s safety record and commitment to workplace safety should be a key consideration when choosing a steel fabrication company in Australia.

-

Facet 1: Safety record

A company’s safety record is a reflection of its commitment to workplace safety. A company with a good safety record has a history of few accidents and incidents. This indicates that the company has effective safety policies and procedures in place, and that employees are properly trained and supervised.

-

Facet 2: Safety culture

A company’s safety culture refers to the attitudes, beliefs, and behaviors that employees have towards safety. A company with a strong safety culture has employees who are committed to working safely and who take personal responsibility for their own safety and the safety of others.

-

Facet 3: Training and education

Proper training and education are essential for ensuring that employees are aware of the hazards associated with steel fabrication and that they know how to work safely. A company that provides comprehensive training and education to its employees is demonstrating its commitment to workplace safety.

-

Facet 4: Compliance with safety regulations

Steel fabrication companies in Australia must comply with a number of safety regulations. These regulations are designed to protect employees from hazards such as falls, electrical shocks, and exposure to hazardous substances. A company that complies with all applicable safety regulations is demonstrating its commitment to workplace safety.

By considering a company’s safety record, safety culture, training and education programs, and compliance with safety regulations, you can choose a steel fabrication company in Australia that is committed to workplace safety and that will provide a safe working environment for its employees.

Customer service

In the competitive steel fabrication industry in Australia, customer service plays a crucial role in building strong relationships with clients and ensuring their satisfaction. Exceptional customer service can differentiate a company from its competitors and contribute to its long-term success.

-

Responsiveness and communication

Prompt and effective communication is essential in building trust and maintaining positive relationships with customers. Steel fabrication companies that are highly responsive to inquiries, provide regular updates on project progress, and proactively address any concerns demonstrate their commitment to customer satisfaction.

-

Technical expertise and support

In the complex field of steel fabrication, customers rely on companies to provide expert advice and support throughout the project lifecycle. Companies with knowledgeable staff who can offer technical guidance, troubleshoot issues, and provide innovative solutions can build strong partnerships with their clients.

-

Flexibility and customization

Steel fabrication projects often require customization to meet specific requirements. Companies that are willing to adapt their services to meet the unique needs of their clients, offer tailored solutions, and accommodate changes during the fabrication process demonstrate a commitment to customer satisfaction.

-

After-sales support

Excellent customer service extends beyond the completion of a project. Steel fabrication companies that provide ongoing support, maintenance advice, and warranty services show that they value long-term relationships and are committed to the satisfaction of their clients.

By prioritizing customer service, steel fabrication companies in Australia can foster trust, build strong relationships, and establish themselves as reliable and valued partners in the industry.

Location

When choosing a steel fabrication company in Australia, the location of the company’s facilities is an important factor to consider. The proximity of the fabrication facility to your project site can have a significant impact on the cost and efficiency of your project.

-

Proximity to raw materials

Steel fabrication companies that are located near sources of raw materials, such as iron ore and coal, have a competitive advantage in terms of cost and availability of materials. This can result in lower prices for steel fabrication services.

-

Transportation costs

The cost of transporting steel components from the fabrication facility to your project site can be a significant factor in the overall cost of your project. Choosing a steel fabrication company that is located close to your project site can help to reduce transportation costs.

-

Delivery time

The delivery time of steel components is another important factor to consider. Choosing a steel fabrication company that is located close to your project site can help to reduce delivery time, which can be critical for projects with tight deadlines.

-

Environmental impact

The transportation of steel components over long distances can have a negative impact on the environment. Choosing a steel fabrication company that is located close to your project site can help to reduce the environmental impact of your project.

By considering the location of a steel fabrication company’s facilities in relation to your project site, you can choose a company that can provide you with cost-effective, efficient, and environmentally friendly steel fabrication services.

Insurance

In the steel fabrication industry in Australia, insurance plays a vital role in protecting companies and their clients from financial risks and liabilities. Steel fabrication processes involve the use of heavy machinery, hazardous materials, and complex engineering, making it essential for companies to carry adequate insurance coverage to mitigate potential risks.

-

Public Liability Insurance

Public liability insurance protects companies against claims for injuries or property damage caused to third parties during the course of their operations. This type of insurance is essential for steel fabrication companies, as they often work on construction sites or other public areas where accidents can occur.

-

Product Liability Insurance

Product liability insurance protects companies against claims for injuries or property damage caused by defective products. This type of insurance is important for steel fabrication companies, as they are responsible for the quality and safety of the steel components they produce.

-

Workers’ Compensation Insurance

Workers’ compensation insurance provides coverage for employees who are injured or become ill as a result of their work. This type of insurance is mandatory for all employers in Australia, including steel fabrication companies.

-

Professional Indemnity Insurance

Professional indemnity insurance protects companies against claims for financial losses resulting from errors or omissions in their professional advice or services. This type of insurance is important for steel fabrication companies that provide engineering or design services.

By carrying adequate insurance coverage, steel fabrication companies in Australia can protect themselves from financial risks, ensure the safety of their employees and the community, and maintain the trust and confidence of their clients.

Certifications

Certifications play a crucial role in the steel fabrication industry in Australia, serving as a testament to a company’s commitment to quality, safety, and adherence to industry standards. Certifications provide independent verification of a company’s capabilities, processes, and products, giving clients confidence in their ability to deliver high-quality steel fabrication services.

One of the most important certifications for steel fabrication companies in Australia is the ISO 9001 certification. ISO 9001 is an international standard that sets out the requirements for a quality management system. Companies that are ISO 9001 certified have demonstrated that they have a robust quality management system in place, which covers all aspects of their operations, from design and engineering to fabrication and installation.

Another important certification for steel fabrication companies in Australia is the AS/NZS 1554.1 certification. AS/NZS 1554.1 is an Australian/New Zealand standard that sets out the requirements for the structural steelwork of buildings. Companies that are AS/NZS 1554.1 certified have demonstrated that they have the knowledge and expertise to fabricate and install structural steelwork that meets the highest safety and quality standards.

In addition to these two major certifications, there are a number of other industry-specific certifications that steel fabrication companies in Australia may hold. These certifications can cover a wide range of areas, such as welding, painting, and fire protection. Companies that hold these certifications have demonstrated that they have the expertise and experience to provide high-quality services in these specific areas.

When choosing a steel fabrication company in Australia, it is important to consider the certifications that the company holds. Certifications provide independent verification of a company’s quality, safety, and adherence to industry standards. By choosing a company that holds the appropriate certifications, you can be confident that you are getting a high-quality product that meets your specific needs.

Table: Common certifications held by steel fabrication companies in Australia

| Certification | Description |

|---|---|

| ISO 9001 | International standard for quality management systems |

| AS/NZS 1554.1 | Australian/New Zealand standard for the structural steelwork of buildings |

| AWS D1.1 | American Welding Society standard for structural welding |

| AS/NZS 2312.1 | Australian/New Zealand standard for hot-dip galvanizing |

| AS/NZS 1670.1 | Australian/New Zealand standard for powder coating |

Reputation

When choosing a steel fabrication company in Australia, it is important to consider the company’s reputation. A company with a good reputation is more likely to be reliable, trustworthy, and to produce high-quality work. There are a number of factors that can contribute to a company’s reputation, including:

-

Customer reviews

Customer reviews can provide valuable insights into a company’s reputation. Positive customer reviews indicate that a company is reliable, trustworthy, and produces high-quality work. Negative customer reviews, on the other hand, can be a red flag.

-

Industry awards

Industry awards are another indication of a company’s reputation. Companies that have won industry awards are recognized for their high-quality work, customer service, and innovation.

-

Online presence

A company’s online presence can also provide insights into its reputation. A company with a strong online presence is more likely to be seen as a leader in the industry. A company with a negative online presence, on the other hand, may be seen as less reputable.

-

Word-of-mouth

Word-of-mouth is still one of the most powerful forms of marketing. If you hear good things about a company from friends, family, or colleagues, it is a good sign that the company has a good reputation.

By considering a company’s reputation, you can choose a steel fabrication company that is more likely to meet your needs and expectations.

Sustainability

In the steel fabrication industry in Australia, sustainability has emerged as a key differentiator, as companies strive to minimize their environmental impact and embrace responsible practices. A company’s commitment to sustainability encompasses various facets, directly impacting its operations and the broader community.

-

Environmental management systems

Steel fabrication companies can implement environmental management systems, such as ISO 14001, to establish a framework for identifying, controlling, and reducing their environmental footprint. These systems encompass measures to minimize waste, conserve energy, and reduce emissions.

-

Sustainable material sourcing

Sustainable material sourcing involves procuring raw materials from suppliers who adhere to environmentally responsible practices. Steel fabrication companies can prioritize recycled content, low-carbon steel, and materials from sustainably managed forests to reduce their impact on natural resources.

-

Waste reduction and recycling

Steel fabrication processes inevitably generate waste. Sustainable companies implement comprehensive waste management strategies to minimize landfill contributions. This includes recycling scrap metal, reusing materials, and partnering with waste management providers that prioritize environmentally sound disposal practices.

-

Energy efficiency

Energy consumption is a significant factor in steel fabrication. Sustainable companies invest in energy-efficient technologies, such as LED lighting, variable speed drives, and optimized production processes, to reduce their energy footprint and operating costs while minimizing greenhouse gas emissions.

By embracing sustainability, steel fabrication companies in Australia demonstrate their commitment to responsible operations, contribute to a greener industry, and meet the evolving expectations of environmentally conscious clients and stakeholders.

FAQs about Steel Fabrication Companies in Australia

Steel fabrication is a vital industry in Australia, supporting the construction, infrastructure, and manufacturing sectors. Here are answers to some frequently asked questions about steel fabrication companies in Australia:

Question 1: What services do steel fabrication companies in Australia offer?

Steel fabrication companies in Australia offer a wide range of services, including design, engineering, fabrication, and installation of steel structures. They can work with various types of steel, including structural steel, stainless steel, and aluminum.

Question 2: How do I choose the right steel fabrication company in Australia?

When choosing a steel fabrication company in Australia, consider factors such as experience, expertise, capacity, reputation, and customer service. It’s also important to ensure that the company is certified and insured.

Question 3: What are the benefits of using a steel fabrication company in Australia?

Using a steel fabrication company in Australia offers several benefits, including access to skilled professionals, high-quality materials, and cutting-edge technology. Steel fabrication companies can also help you save time and money by providing efficient and cost-effective solutions.

Question 4: How can I ensure the quality of steel fabrication services in Australia?

To ensure the quality of steel fabrication services in Australia, look for companies that are certified to relevant industry standards, such as ISO 9001 and AS/NZS 1554.1. Additionally, check their track record, read customer testimonials, and visit their facilities if possible.

Question 5: What are the latest trends in steel fabrication in Australia?

The steel fabrication industry in Australia is constantly evolving, with new technologies and techniques emerging. Some of the latest trends include the use of digital fabrication tools, automation, and sustainable practices.

Question 6: What is the future of steel fabrication in Australia?

The future of steel fabrication in Australia looks promising, with continued growth expected in the construction and infrastructure sectors. Steel fabrication companies are also focusing on innovation and sustainability to meet the evolving needs of the industry.

By understanding these FAQs, you can make informed decisions when choosing and working with steel fabrication companies in Australia.

Transition to the next article section:

For more information on steel fabrication companies in Australia, explore our comprehensive guide.

Tips for Choosing and Working with Steel Fabrication Companies in Australia

Choosing the right steel fabrication company in Australia is crucial for the success of your project. Here are some tips to help you make an informed decision and ensure a smooth collaboration:

Tip 1: Define your project requirements

Clearly outline the scope of your project, including the type of steel structure, dimensions, design specifications, and budget. This will help you narrow down your search to companies that specialize in your specific requirements.

Tip 2: Research potential companies

Thoroughly research potential steel fabrication companies in Australia. Check their websites, read customer testimonials, and examine their portfolios to assess their experience, expertise, and capabilities.

Tip 3: Consider certifications and industry memberships

Look for companies that are certified to relevant industry standards, such as ISO 9001 and AS/NZS 1554.1. Industry memberships, such as the Australian Steel Institute, also indicate a commitment to quality and best practices.

Tip 4: Request quotes and compare services

Obtain quotes from several companies and compare their services, pricing, and timelines. Consider not only the initial cost but also the value for money and the long-term performance of the steel structure.

Tip 5: Visit their facilities and meet the team

If possible, visit the facilities of potential steel fabrication companies to assess their equipment, safety measures, and the expertise of their team. Meeting the team in person can provide valuable insights into their professionalism and commitment to customer satisfaction.

Tip 6: Check their insurance and safety record

Ensure that the steel fabrication company you choose has adequate insurance coverage, including public liability and product liability insurance. A good safety record is also essential to minimize risks and ensure a safe working environment.

Tip 7: Establish clear communication and expectations

Establish clear communication channels and set realistic expectations throughout the project. Regular updates, timely responses, and open dialogue are crucial for a successful collaboration.

Tip 8: Foster a collaborative partnership

Treat the steel fabrication company as a partner, not just a vendor. Share your project vision and involve them in the decision-making process. By fostering a collaborative partnership, you can leverage their expertise and achieve the best possible outcome for your project.

By following these tips, you can choose a reputable steel fabrication company in Australia that meets your project requirements, delivers high-quality work, and ensures a smooth and successful collaboration.

Conclusion

The steel fabrication industry in Australia is a vital sector that supports the construction, infrastructure, and manufacturing industries. Steel fabrication companies play a crucial role in shaping the built environment, providing high-quality steel structures that meet the specific requirements of diverse projects.

Choosing the right steel fabrication company is essential for the success of any project. By considering factors such as experience, expertise, capacity, reputation, and customer service, you can select a company that aligns with your project goals and delivers exceptional results. Additionally, fostering a collaborative partnership and establishing clear communication channels are key to ensuring a smooth and successful working relationship.

The steel fabrication industry in Australia is constantly evolving, with new technologies and techniques emerging. Steel fabrication companies are embracing innovation and sustainability to meet the changing needs of the industry and contribute to a greener future. By partnering with reputable and forward-thinking steel fabrication companies, you can harness the latest advancements and achieve the highest standards of quality, safety, and efficiency for your project.