In the realm of heavy industry and construction, precision and durability are paramount. Ram fabrication and welding services play a vital role in meeting these demands, ensuring the creation of robust and reliable structures.

Editor’s Note: Understanding the intricacies of ram fabrication and welding services is essential for professionals seeking exceptional results in their projects.

Through meticulous analysis and in-depth research, we have crafted this guide to empower our readers with the knowledge and insights they need to make informed decisions regarding ram fabrication and welding services. Our comprehensive approach covers key aspects, including:

| Key Differences | Key Takeaways |

|---|---|

| Fabrication vs. Welding | Understanding the distinct processes and their applications |

| Material Selection | Choosing the right materials for optimal performance |

| Quality Control | Ensuring adherence to industry standards and specifications |

Delving into the main article topics, we will explore the following:

- The advantages and applications of ram fabrication and welding services

- Factors to consider when selecting a ram fabrication and welding service provider

- Best practices for ensuring project success

- Common challenges and how to overcome them

- Emerging trends and advancements in ram fabrication and welding technologies

Whether you are a seasoned professional or new to the field, this guide will serve as an invaluable resource, equipping you with the knowledge and confidence to navigate the complexities of ram fabrication and welding services.

Ram Fabrication and Welding Services

Ram fabrication and welding services are critical for industries that demand precision and durability. These services encompass various key aspects, each playing a vital role in the success of a project:

- Materials: Choosing the right materials, such as steel, aluminum, or stainless steel, is crucial for ensuring the longevity and performance of the fabricated components.

- Design: Skilled engineers design and create fabrication drawings that guide the construction process, ensuring accuracy and efficiency.

- Fabrication: State-of-the-art equipment and techniques are used to cut, shape, and assemble metal components with precision.

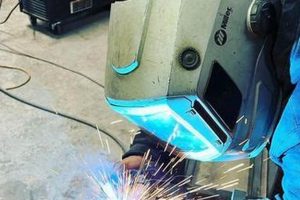

- Welding: Certified welders employ specialized techniques to join metal components securely and ensure structural integrity.

- Quality Control: Rigorous inspections and testing are conducted throughout the process to guarantee that fabricated and welded components meet industry standards.

- Project Management: Effective project management ensures timely delivery, cost control, and adherence to specifications.

- Expertise: Choosing a reputable service provider with experienced engineers, fabricators, and welders is essential for achieving optimal results.

These key aspects are interconnected and impact the overall quality, durability, and performance of fabricated and welded components. For instance, selecting the appropriate materials and employing skilled welders directly influences the strength and longevity of the final product. Effective project management ensures that projects are completed within budget and on schedule, while rigorous quality control guarantees that components meet the required specifications.

Understanding and considering these essential aspects is crucial for businesses seeking reliable and high-quality ram fabrication and welding services. By partnering with experienced service providers and adhering to industry best practices, organizations can ensure the successful execution of their projects and achieve their desired outcomes.

Materials

In the realm of ram fabrication and welding services, the selection of appropriate materials is paramount for achieving optimal results. The choice of material directly impacts the durability, performance, and longevity of the fabricated components, influencing the overall success of the project.

-

Material Properties and Applications:

Different materials possess distinct properties that make them suitable for specific applications. Steel, known for its strength and durability, is commonly used in structural components and heavy machinery. Aluminum, with its lightweight and corrosion resistance, is ideal for aerospace and marine applications. Stainless steel, offering excellent corrosion resistance and high strength, is widely used in food processing equipment and medical devices.

-

Material Compatibility and Welding:

The compatibility of materials is crucial for successful welding. Proper material selection ensures that the welded joints are strong and durable, maintaining the integrity of the fabricated components. For instance, welding steel requires specific welding techniques and compatible filler materials to achieve a strong and reliable bond.

-

Cost and Availability:

Material costs and availability play a significant role in the selection process. Striking a balance between performance requirements and cost constraints is essential for project feasibility. Exploring alternative materials or optimizing material usage can help reduce costs while maintaining the desired quality.

-

Industry Standards and Regulations:

Adhering to industry standards and regulations is imperative when selecting materials for ram fabrication and welding services. These standards ensure that the fabricated components meet specific performance criteria and safety requirements. Understanding the applicable codes and regulations is crucial for selecting compliant materials.

By carefully considering the material properties, compatibility, cost, availability, and industry regulations, businesses can make informed decisions regarding material selection for their ram fabrication and welding projects. Choosing the right materials lays the foundation for durable, high-performing, and cost-effective fabricated components that meet the demands of various industries.

Design

In the realm of ram fabrication and welding services, skilled engineers play a pivotal role in translating design concepts into tangible, high-quality components. Their expertise in design and drafting ensures accuracy, efficiency, and adherence to specifications throughout the fabrication process.

-

Component Design and Optimization

Engineers meticulously design each component, considering factors such as functionality, strength, and manufacturability. They optimize designs to reduce material usage, minimize fabrication time, and enhance overall performance.

-

Fabrication Drawings and Instructions

Detailed fabrication drawings serve as blueprints for the fabrication process. Engineers create these drawings, specifying dimensions, tolerances, and assembly instructions. They also provide welding procedures, ensuring proper joint preparation and welding techniques.

-

Quality Control and Inspection

Engineers oversee the fabrication process, conducting regular inspections to ensure that components meet design specifications. They verify dimensions, weld quality, and overall workmanship, ensuring that the fabricated components meet the required standards.

-

Collaboration and Communication

Engineers collaborate closely with fabricators and welders, providing technical guidance and resolving any issues that arise during the fabrication process. Effective communication ensures that all parties are aligned, leading to efficient and accurate execution of the project.

The intricate designs and precise fabrication drawings created by skilled engineers serve as the foundation for high-quality ram fabrication and welding services. Their expertise ensures that the fabricated components meet the desired specifications, perform reliably, and contribute to the overall success of the project.

Fabrication

In the realm of ram fabrication and welding services, fabrication plays a crucial role in transforming raw materials into high-quality components that meet precise specifications. State-of-the-art equipment and techniques are employed to cut, shape, and assemble metal components with unmatched precision, ensuring the structural integrity and performance of the final product.

-

Precision Cutting:

Advanced cutting technologies, such as laser cutting and waterjet cutting, enable precise and intricate cuts in various metal alloys. These techniques minimize material waste and ensure accurate component dimensions, reducing the need for rework and enhancing overall efficiency.

-

Expert Shaping and Forming:

Skilled fabricators utilize specialized equipment, such as press brakes and rolling machines, to shape and form metal components. They manipulate the material, applying controlled force and heat, to achieve the desired shapes and contours, ensuring a perfect fit and optimal performance.

-

Accurate Assembly and Welding Preparation:

Fabrication also involves precise assembly of components prior to welding. Skilled technicians align and secure the components using jigs and fixtures, ensuring proper alignment and minimizing distortion during welding. This meticulous preparation ensures strong and durable welded joints.

-

Quality Control and Inspection:

Throughout the fabrication process, rigorous quality control measures are implemented to verify the accuracy and quality of the components. Fabricators conduct regular inspections, utilizing measuring tools and gauges, to ensure that each component meets the specified tolerances and design requirements.

The precise fabrication techniques employed in ram fabrication and welding services are essential for achieving the high levels of accuracy, durability, and performance demanded by various industries. By leveraging state-of-the-art equipment and skilled professionals, these services deliver exceptional results, ensuring the integrity and reliability of fabricated components.

Welding

In the realm of ram fabrication and welding services, welding plays a pivotal role in creating robust and durable structures. Certified welders, equipped with specialized expertise and techniques, are entrusted with the critical task of joining metal components securely, ensuring their structural integrity and ability to withstand demanding applications.

-

Precision and Accuracy:

Welding in ram fabrication demands precision and accuracy to achieve the desired strength and performance. Certified welders utilize advanced techniques, such as TIG welding and MIG welding, to create precise and reliable welds that meet stringent quality standards.

-

Material Compatibility:

The compatibility of welding techniques with different materials is crucial in ram fabrication. Welders possess the knowledge and experience to select the appropriate welding methods for various metals, ensuring strong and durable joints that maintain the integrity of the fabricated components.

-

Structural Integrity:

The structural integrity of welded components is paramount in ram fabrication. Certified welders employ specialized techniques to minimize distortion and ensure that the welded joints can withstand the forces and loads encountered in demanding applications.

-

Quality Control and Inspection:

Rigorous quality control measures are implemented throughout the welding process. Welders conduct thorough inspections using non-destructive testing methods to verify the quality of the welds and ensure they meet the required specifications and industry standards.

In summary, the expertise of certified welders in employing specialized techniques is indispensable in ram fabrication and welding services. Their ability to create precise, reliable, and structurally sound welds ensures the integrity and longevity of fabricated components, meeting the demands of various industries and applications.

Quality Control

In the realm of ram fabrication and welding services, quality control is paramount, ensuring that fabricated and welded components meet stringent industry standards. Rigorous inspections and testing are conducted throughout the process to verify the quality and integrity of these components.

The importance of quality control in ram fabrication and welding services cannot be overstated. It directly impacts the safety, reliability, and performance of the fabricated components. For instance, in the construction industry, structural components must meet specific load-bearing capacities and safety requirements. Without proper quality control, these components may fail under stress, posing significant risks to life and property.

To ensure quality, ram fabrication and welding service providers implement comprehensive quality control measures. These measures include visual inspections, dimensional checks, non-destructive testing (NDT) methods, and mechanical testing. Visual inspections involve examining the components for any surface defects or imperfections. Dimensional checks verify that the components conform to the specified dimensions and tolerances. NDT methods, such as ultrasonic testing and radiographic testing, are employed to detect internal flaws and defects that may not be visible to the naked eye.

In summary, quality control is an indispensable aspect of ram fabrication and welding services. By adhering to rigorous inspection and testing procedures, service providers ensure that fabricated and welded components meet the highest standards of quality, ensuring their safety, reliability, and performance.

Key Insights:

- Quality control is crucial for ensuring the safety, reliability, and performance of ram fabricated and welded components.

- Rigorous inspections and testing are essential for verifying the quality and integrity of these components.

- Non-destructive testing (NDT) methods play a vital role in detecting internal flaws and defects.

- Adherence to quality control standards is essential for meeting industry requirements and ensuring customer satisfaction.

Project Management

In the realm of ram fabrication and welding services, effective project management plays a pivotal role in ensuring the successful execution and completion of projects. It encompasses a comprehensive range of activities that directly impact the quality, efficiency, and overall outcome of fabrication and welding endeavors.

Project management in ram fabrication and welding services involves:

- Planning and Scheduling: Defining project scope, timelines, and milestones, coordinating resources, and establishing clear communication channels.

- Cost Control: Monitoring project expenses, identifying cost-saving opportunities, and ensuring adherence to budget constraints.

- Quality Assurance: Implementing quality control measures throughout the fabrication and welding processes, ensuring compliance with specifications and industry standards.

- Risk Management: Identifying and mitigating potential risks that may impact project timelines, costs, or quality.

- Stakeholder Management: Engaging with clients, contractors, and other stakeholders to manage expectations, resolve issues, and ensure project alignment.

Effective project management brings numerous benefits to ram fabrication and welding services:

- Timely Delivery: Clear planning and scheduling ensure that projects are completed on time, minimizing delays and disruptions.

- Cost Control: Proactive cost monitoring and management prevent cost overruns, ensuring projects are executed within budget.

- Quality Assurance: Rigorous quality control measures guarantee that fabricated and welded components meet specifications, enhancing overall project quality.

- Risk Mitigation: Identifying and addressing risks proactively minimizes the likelihood of disruptions and ensures project success.

- Stakeholder Satisfaction: Effective stakeholder management fosters collaboration, manages expectations, and ensures project outcomes meet the needs of all parties involved.

In summary, effective project management is an indispensable aspect of ram fabrication and welding services. It provides a structured framework for planning, executing, and controlling projects, ensuring timely delivery, cost control, quality assurance, risk mitigation, and stakeholder satisfaction. By embracing robust project management practices, fabrication and welding service providers can enhance their efficiency, optimize their operations, and deliver exceptional results that meet the demands of their clients.

Key Insights:

- Project management is crucial for coordinating resources, managing finances, and ensuring project success in ram fabrication and welding services.

- Effective project management enables timely delivery, cost control, quality assurance, and risk mitigation.

- Clear communication, stakeholder engagement, and proactive risk management are essential for effective project management.

Expertise

In the competitive landscape of ram fabrication and welding services, expertise stands as a cornerstone for achieving optimal outcomes. Choosing a reputable service provider with experienced engineers, fabricators, and welders is paramount for ensuring the quality, reliability, and success of your project.

-

Engineering Expertise:

Skilled engineers bring a wealth of knowledge and experience to the design and development phase of your project. They transform your concepts into detailed fabrication drawings, ensuring structural integrity, functionality, and adherence to industry standards.

-

Fabrication Proficiency:

Experienced fabricators possess the technical skills and specialized equipment to precisely cut, shape, and assemble metal components. Their expertise ensures that each component meets the exact specifications, resulting in a robust and durable final product.

-

Welding Mastery:

Certified welders play a critical role in joining metal components securely and flawlessly. Their mastery of welding techniques guarantees the structural integrity and longevity of your fabricated components, ensuring they withstand demanding operating conditions.

-

Quality Control and Assurance:

Reputable service providers implement rigorous quality control measures throughout the fabrication and welding process. Experienced professionals conduct thorough inspections and testing to ensure that every component meets the highest standards of quality and workmanship.

Partnering with a service provider that possesses these areas of expertise provides numerous advantages for your ram fabrication and welding project. You can expect exceptional craftsmanship, adherence to timelines, cost-effectiveness, and peace of mind knowing that your project is in capable hands. By choosing a reputable service provider with experienced engineers, fabricators, and welders, you lay the foundation for a successful project that meets your exact requirements.

FAQs on Ram Fabrication and Welding Services

This section addresses frequently asked questions, providing valuable insights and dispelling common misconceptions surrounding ram fabrication and welding services:

Question 1: What industries commonly utilize ram fabrication and welding services?

Ram fabrication and welding services are extensively employed in various industries, including construction, automotive, aerospace, and heavy machinery. These services are essential for creating structural components, machine parts, and other critical elements that require precision, durability, and strength.

Question 2: What materials are suitable for ram fabrication and welding?

The selection of materials for ram fabrication and welding depends on the specific application and performance requirements. Common materials used include steel, aluminum, and stainless steel. Each material offers unique properties, such as strength, weight, and corrosion resistance, making them suitable for different project needs.

Question 3: How can I ensure the quality of ram fabrication and welding services?

To ensure quality, consider partnering with reputable service providers a proven track record and certifications. Look for companies that adhere to industry standards and employ experienced engineers, fabricators, and welders. Thorough inspections and testing throughout the fabrication and welding process are also crucial for guaranteeing the integrity and reliability of the final product.

Question 4: What are the benefits of outsourcing ram fabrication and welding services?

Outsourcing ram fabrication and welding services offers several advantages, including access to specialized expertise, cost-effectiveness, and time savings. By partnering with experienced service providers, businesses can leverage their technical knowledge, state-of-the-art equipment, and efficient processes to achieve optimal results.

Question 5: How do I choose the right ram fabrication and welding service provider?

When selecting a ram fabrication and welding service provider, consider factors such as their experience, reputation, technical capabilities, quality control measures, and customer service. Request references, visit their facilities if possible, and evaluate their understanding of your project requirements to make an informed decision.

Question 6: What are the latest trends and advancements in ram fabrication and welding technologies?

The ram fabrication and welding industry is constantly evolving, with new technologies and techniques emerging to enhance efficiency and accuracy. Innovations such as automated welding, robotic fabrication, and advanced inspection methods are transforming the industry, enabling faster production times, improved precision, and higher quality standards.

These FAQs provide valuable insights into various aspects of ram fabrication and welding services. By understanding these key questions and answers, you can make informed decisions, ensure project success, and harness the full potential of these essential services for your industry.

Transition to the next article section: Explore our comprehensive guide to ram fabrication and welding services, covering topics such as materials selection, quality control, project management, and industry trends.

Tips for Ram Fabrication and Welding Services

Optimizing ram fabrication and welding services requires careful planning and execution. Here are some valuable tips to consider:

Tip 1: Partner with Experienced Service Providers

Choose reputable service providers with proven experience and expertise in ram fabrication and welding. Their knowledge and skills ensure project success, adherence to industry standards, and timely delivery.

Tip 2: Define Clear Specifications

Provide clear and detailed specifications for your project. This includes material selection, dimensions, tolerances, and any specific requirements. Clear specifications minimize errors, reduce rework, and ensure the fabricated components meet your exact needs.

Tip 3: Prioritize Quality Control

Implement rigorous quality control measures throughout the fabrication and welding process. Regular inspections and testing ensure the structural integrity, dimensional accuracy, and overall quality of the fabricated components.

Tip 4: Optimize Material Selection

Carefully consider the material selection for your project. Different materials possess unique properties that impact strength, durability, weight, and cost. Choosing the right material ensures optimal performance and longevity of the fabricated components.

Tip 5: Leverage Advanced Techniques

Incorporate advanced fabrication and welding techniques to enhance productivity and precision. Technologies such as laser cutting, robotic welding, and automated inspection can streamline fabrication, improve accuracy, and reduce production time.

Tip 6: Ensure Proper Maintenance

Maintain fabrication and welding equipment regularly to ensure optimal performance and safety. Regular maintenance prevents breakdowns, extends equipment life, and minimizes production downtime.

Tip 7: Invest in Training

Invest in training for engineers, fabricators, and welders to enhance their skills and knowledge. Well-trained professionals can effectively handle complex projects, improve efficiency, and ensure adherence to industry best practices.

Tip 8: Foster Collaboration

Foster open communication and collaboration between engineers, fabricators, and welders. Regular communication ensures that everyone is aligned with project requirements, potential challenges are identified early, and solutions are developed efficiently.

By implementing these tips, you can optimize your ram fabrication and welding services, ensuring high-quality, cost-effective, and timely project execution.

Transition to the article’s conclusion: Explore our comprehensive guide to ram fabrication and welding services, covering topics such as materials selection, quality control, project management, and industry trends.

Conclusion

Ram fabrication and welding services play a vital role in various industries, enabling the creation of robust and durable structures and components. This comprehensive guide has explored the key aspects of these services, delving into materials selection, quality control, project management, and the latest advancements in fabrication and welding technologies.

Choosing reputable service providers with proven expertise is crucial for ensuring project success and adherence to industry standards. By partnering with experienced professionals, businesses can leverage their technical knowledge, state-of-the-art equipment, and efficient processes to achieve optimal results.

Furthermore, optimizing material selection, implementing rigorous quality control measures, and embracing advanced fabrication and welding techniques can enhance productivity, precision, and the overall quality of fabricated components. Regular maintenance, training, and fostering collaboration among engineers, fabricators, and welders are also essential for ensuring smooth project execution.

Ram fabrication and welding services are constantly evolving, with new technologies and techniques emerging to meet the demands of modern industries. By understanding the key principles and best practices outlined in this guide, businesses and professionals can harness the full potential of these services to achieve exceptional outcomes.