In need of durable and reliable steel fabrication services in Dallas? We’ve done the research and put together this comprehensive guide to help you find the best steel fabricators in the city.

Editor’s Notes: Steel fabrication is a critical process in various industries, ensuring the production of high-quality steel structures and components. Dallas, being a hub for construction and manufacturing, offers a wide range of steel fabrication companies catering to diverse project requirements.

To assist you in making informed decisions, we’ve analyzed and compared different steel fabricators in Dallas, considering factors such as expertise, capabilities, and customer reviews. Our guide provides valuable insights to help you select the most suitable provider for your project.

Key Differences:

| Factor | Key Differences |

|---|---|

| Expertise | Specialization in specific fabrication techniques and materials, such as welding, cutting, and forming. |

| Capabilities | Range of services offered, including design, engineering, and installation. |

| Customer Service | Responsiveness, communication, and ability to meet project deadlines. |

Transition to main article topics:

- Types of Steel Fabrication Services in Dallas

- Choosing the Right Steel Fabricator

- Benefits of Using Steel Fabrication Services

- Case Studies and Examples of Steel Fabrication in Dallas

- Conclusion

Steel Fabrication Dallas

Steel fabrication is a vital process in the construction industry, involving the creation of steel structures and components. In Dallas, steel fabrication services are essential for various projects, ranging from skyscrapers to bridges.

- Expertise: Dallas fabricators specialize in diverse techniques, ensuring high-quality results.

- Capabilities: Services encompass design, engineering, and installation, meeting project requirements.

- Materials: Steel fabricators in Dallas work with various steel grades, including carbon steel and stainless steel.

- Industries: Steel fabrication supports industries such as construction, manufacturing, and transportation.

- Codes and Standards: Dallas fabricators adhere to strict codes and standards, guaranteeing safety and reliability.

- Technology: Advanced technology, such as CNC machines and welding robots, enhances efficiency and precision.

- Collaboration: Steel fabricators collaborate with architects, engineers, and contractors to ensure project success.

These key aspects highlight the diverse dimensions of steel fabrication in Dallas. From expertise and capabilities to materials and technology, each aspect contributes to the production of high-quality steel structures that shape the city’s skyline and infrastructure.

Expertise

The expertise of Dallas fabricators is a cornerstone of the city’s steel fabrication industry. Their specialized techniques and skills enable them to produce high-quality steel structures and components that meet the demands of various projects.

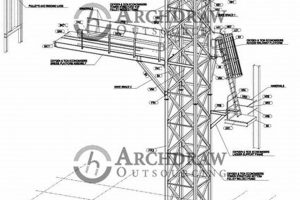

One key aspect of this expertise lies in the fabrication techniques employed. Dallas fabricators utilize advanced methods such as CNC cutting, robotic welding, and press brake forming. These techniques ensure precision, efficiency, and consistency in the fabrication process, leading to high-quality results.

Furthermore, Dallas fabricators possess in-depth knowledge of different steel grades and their properties. This expertise allows them to select the most appropriate steel for each project, considering factors such as strength, durability, and cost. By matching the right steel grade to the specific application, fabricators can optimize performance and ensure the longevity of the steel structures.

The expertise of Dallas fabricators extends beyond technical skills. They also have a deep understanding of industry standards and codes, ensuring that their work meets the highest levels of safety and quality. This commitment to excellence has earned Dallas fabricators a reputation for producing reliable and durable steel structures that stand the test of time.

In summary, the expertise of Dallas fabricators is a critical component of the city’s steel fabrication industry. Their specialized techniques, knowledge of steel grades, and adherence to industry standards enable them to deliver high-quality steel structures that meet the diverse needs of the construction, manufacturing, and transportation sectors.

Capabilities

The capabilities of Dallas steel fabricators extend beyond fabrication itself. Many companies offer comprehensive services that encompass design, engineering, and installation, ensuring a seamless project experience for clients.

The design phase is crucial, as it sets the foundation for the entire project. Dallas fabricators collaborate with architects and engineers to create detailed plans that meet the specific requirements of each project. This involves understanding the intended use of the steel structure, the loads it will bear, and the environmental conditions it will face.

Engineering plays a vital role in ensuring the structural integrity and safety of steel fabrications. Dallas fabricators employ skilled engineers who analyze designs, calculate stresses, and determine the appropriate materials and techniques to use. This expertise ensures that steel structures are built to withstand the test of time and meet industry standards.

Installation is the final stage of the process, where the fabricated steel components are assembled and erected on site. Dallas fabricators have experienced crews who specialize in the safe and efficient installation of steel structures. They work closely with general contractors and other trades to ensure that the project is completed on time and within budget.

The comprehensive capabilities of Dallas steel fabricators provide several benefits to clients. By offering design, engineering, and installation services under one roof, fabricators streamline the project process, reducing the need for multiple contractors and improving coordination. This leads to increased efficiency, cost savings, and better quality control.

In addition, Dallas fabricators are committed to meeting the unique requirements of each project. They work closely with clients to understand their specific needs and tailor their services accordingly. This flexibility ensures that clients receive customized solutions that meet their exact specifications.

Overall, the capabilities of Dallas steel fabricators, encompassing design, engineering, and installation, are essential for meeting the diverse project requirements of the city’s construction industry. By providing comprehensive services, fabricators streamline the project process, enhance quality, and deliver cost-effective solutions that meet the unique needs of each client.

Materials

The choice of materials is a critical aspect of steel fabrication in Dallas, as it directly impacts the properties and performance of the final product. Steel fabricators in Dallas utilize a range of steel grades, each with its own unique characteristics and applications.

Carbon steel is the most commonly used grade in steel fabrication. It is known for its strength, durability, and cost-effectiveness. Carbon steel is suitable for a wide range of applications, including structural components, machinery, and automotive parts.

Stainless steel is another popular grade used in steel fabrication. It is resistant to corrosion and rust, making it ideal for applications where durability is paramount. Stainless steel is commonly used in food processing equipment, medical devices, and architectural elements.

The selection of the appropriate steel grade depends on several factors, including the intended use of the fabricated component, the environmental conditions it will be exposed to, and the desired strength and durability.

For example, in the construction of high-rise buildings, structural steel is typically used due to its high strength-to-weight ratio. In contrast, stainless steel is often preferred for applications involving exposure to corrosive environments, such as chemical processing plants or marine structures.

The availability of various steel grades in Dallas allows fabricators to meet the diverse needs of their clients. By carefully selecting the right material for each project, fabricators can ensure that the final product meets the required performance and durability standards.

Table: Properties and Applications of Common Steel Grades

| Steel Grade | Properties | Applications |

|---|---|---|

| Carbon Steel | Strong, durable, cost-effective | Structural components, machinery, automotive parts |

| Stainless Steel | Corrosion-resistant, durable | Food processing equipment, medical devices, architectural elements |

| Alloy Steel | High strength, wear resistance | Gears, shafts, cutting tools |

| Tool Steel | Exceptional hardness, wear resistance | Cutting tools, dies, molds |

Industries

Steel fabrication plays a vital role in supporting the construction, manufacturing, and transportation industries in Dallas. These industries rely heavily on steel structures, components, and equipment to operate efficiently and safely.

In the construction industry, steel fabrication is essential for the of skyscrapers, bridges, stadiums, and other large-scale structures. Steel’s strength, durability, and versatility make it an ideal material for these applications. Steel fabricators in Dallas work closely with architects and engineers to design and produce steel structures that meet the specific requirements of each project.

In the manufacturing industry, steel fabrication is used to create a wide range of products, including machinery, equipment, and vehicles. Steel’s strength and durability make it well-suited for these applications, as it can withstand heavy loads and harsh operating conditions. Dallas steel fabricators have the expertise and capabilities to produce high-quality steel components that meet the demanding requirements of the manufacturing industry.

In the transportation industry, steel fabrication is essential for the construction of ships, trains, and aircraft. Steel’s strength and durability make it an ideal material for these applications, as it can withstand the stresses of transportation and provide a safe and reliable means of travel. Dallas steel fabricators work closely with transportation companies to design and produce steel structures and components that meet the specific requirements of the industry.

The connection between steel fabrication and these industries is evident in the numerous iconic structures and products that have been built in Dallas using steel. From the Reunion Tower to the Margaret Hunt Hill Bridge, steel has played a vital role in shaping the city’s skyline and infrastructure.

Table: Steel Fabrication Applications in Key Industries

| Industry | Applications |

|---|---|

| Construction | Skyscrapers, bridges, stadiums, buildings |

| Manufacturing | Machinery, equipment, vehicles |

| Transportation | Ships, trains, aircraft |

Codes and Standards

In the realm of steel fabrication in Dallas, adherence to codes and standards is paramount. These guidelines serve as the cornerstone of safety, ensuring that steel structures and components meet the highest levels of quality and reliability.

-

Building Codes:

Building codes, such as the International Building Code (IBC) and the American Institute of Steel Construction (AISC) code, establish minimum requirements for the design, fabrication, and installation of steel structures. Dallas fabricators strictly follow these codes to ensure that buildings are safe and habitable, withstanding various loads and environmental conditions.

-

Industry Standards:

Industry standards, such as those set by the American Welding Society (AWS) and the American Society of Mechanical Engineers (ASME), provide specific guidelines for welding and fabrication techniques. Dallas fabricators adhere to these standards to ensure that welds meet the required strength, durability, and quality.

-

Quality Control:

To guarantee the reliability of their products, Dallas fabricators implement rigorous quality control measures throughout the fabrication process. These measures include inspections, testing, and documentation to ensure that each component meets the specified standards.

The adherence to codes and standards by Dallas fabricators has several implications:

- Public Safety: By meeting the requirements of building codes, steel fabricators help ensure the safety of occupants in buildings and other structures.

- Structural Integrity: Compliance with industry standards guarantees the structural integrity of steel components, preventing failures and ensuring long-term performance.

- Quality Assurance: Quality control measures provide assurance that steel fabrications meet the intended design specifications, enhancing reliability and durability.

In conclusion, the adherence to codes and standards is an integral part of steel fabrication in Dallas. It ensures the safety, reliability, and quality of steel structures and components, contributing to the city’s reputation for excellence in construction and manufacturing.

Technology

In the realm of steel fabrication in Dallas, advanced technology plays a pivotal role in enhancing efficiency and precision. The integration of CNC machines and welding robots has revolutionized the industry, leading to numerous benefits for fabricators and end-users alike.

- Precision and Accuracy: CNC machines, or computer numerical control machines, are programmed to follow precise instructions, resulting in highly accurate cuts, bends, and welds. This level of precision is crucial for complex steel fabrications, ensuring that components fit together seamlessly and meet exact specifications.

- Increased Efficiency: Welding robots can perform repetitive welding tasks with greater speed and consistency than manual welding. This automation significantly reduces production time, allowing fabricators to meet tight deadlines and increase overall productivity.

- Reduced Labor Costs: The use of CNC machines and welding robots reduces the need for manual labor, leading to lower labor costs for fabricators. This cost savings can be passed on to customers, making steel fabrication more affordable.

- Improved Quality Control: Advanced technology allows fabricators to monitor and control the fabrication process more closely. This enhanced quality control ensures that products meet the highest standards of quality and consistency.

The adoption of advanced technology in steel fabrication has had a profound impact on the industry in Dallas. Fabricators are able to produce complex steel structures and components with greater precision, efficiency, and cost-effectiveness. This has led to increased innovation and competitiveness in the construction, manufacturing, and transportation sectors.

Collaboration

In the dynamic landscape of steel fabrication in Dallas, collaboration serves as a cornerstone for project success. Steel fabricators work hand-in-hand with architects, engineers, and contractors throughout the project lifecycle, fostering a spirit of teamwork and shared responsibility.

-

Design Integration:

Collaboration enables seamless integration between design intent and fabrication capabilities. Architects and engineers provide detailed plans and specifications, while fabricators offer valuable insights on material selection, constructability, and cost optimization. This collaborative approach ensures that the final product aligns precisely with the project’s vision. -

Technical Expertise:

Steel fabricators possess specialized knowledge and expertise in steel fabrication techniques. By collaborating with engineers, they can optimize structural designs, ensuring that the fabricated components meet the required strength, durability, and safety standards. Engineers provide calculations and analysis, while fabricators translate these technical requirements into practical solutions. -

Project Coordination:

Collaboration streamlines project coordination and communication among all stakeholders. Regular meetings, site visits, and open dialogue facilitate the exchange of information, allowing for timely decision-making and proactive problem-solving. This collaborative approach minimizes delays and ensures that the project progresses smoothly from design to completion. -

Quality Control:

Collaboration fosters a shared commitment to quality throughout the fabrication process. Fabricators, architects, and contractors work together to establish and maintain rigorous quality control standards. Inspections, testing, and documentation are conducted at various stages to ensure that the fabricated components meet the specified requirements and industry best practices.

The collaborative spirit that exists in steel fabrication in Dallas contributes significantly to the city’s reputation for excellence in construction and manufacturing. By working together, architects, engineers, contractors, and fabricators deliver high-quality steel structures that meet the unique needs of each project, shaping the city’s skyline and infrastructure.

Frequently Asked Questions about Steel Fabrication in Dallas

This section addresses common questions and misconceptions surrounding steel fabrication in Dallas, providing concise and informative answers.

Question 1: What are the benefits of using steel fabrication services in Dallas?

Steel fabrication offers numerous advantages, including access to skilled professionals, advanced technology, and high-quality materials. Dallas fabricators possess expertise in various techniques, ensuring precision, efficiency, and adherence to industry standards. They utilize state-of-the-art equipment and collaborate with experienced engineers and contractors to deliver exceptional results.

Question 2: How do I choose the right steel fabricator in Dallas?

Selecting the appropriate steel fabricator is crucial. Consider factors such as their experience, capabilities, reputation, and customer service. Look for fabricators who specialize in the specific type of project you require and have a proven track record of success. Check online reviews, industry certifications, and ask for references to assess their reliability and quality of work.

Question 3: What is the typical lead time for steel fabrication projects in Dallas?

Lead times vary depending on the complexity and size of the project. However, most Dallas fabricators can provide estimates based on their production capacity and schedule. It’s advisable to plan ahead and allow sufficient time for design, engineering, fabrication, and installation to ensure a smooth project execution.

Question 4: How do I ensure the quality of steel fabrication services in Dallas?

Quality assurance is paramount. Look for fabricators who adhere to industry standards and codes, such as those established by the American Institute of Steel Construction (AISC). Request certifications and documentation to verify their quality control processes. Visit the fabrication facility, if possible, to assess their equipment and workmanship firsthand.

Question 5: What are the cost considerations for steel fabrication in Dallas?

The cost of steel fabrication depends on several factors, including the type of steel, complexity of the design, and quantity required. Dallas fabricators typically provide detailed quotes outlining the materials, labor, and any additional services included. It’s important to compare quotes from multiple fabricators and consider the overall value and quality they offer.

Question 6: How can I find reputable steel fabrication companies in Dallas?

There are several resources available to locate reputable steel fabrication companies in Dallas. Industry directories, online platforms, and local construction associations can provide a list of qualified fabricators. Attend industry events and network with professionals to gather recommendations and insights.

By addressing these frequently asked questions, we aim to provide a comprehensive understanding of steel fabrication in Dallas. Remember to conduct thorough research, ask informed questions, and partner with experienced professionals to ensure a successful project outcome.

Transition to the next article section: Exploring the latest advancements in steel fabrication techniques

Tips for Exceptional Steel Fabrication in Dallas

Steel fabrication is a crucial process that requires precision, expertise, and adherence to industry standards. To achieve exceptional results in steel fabrication projects in Dallas, consider these valuable tips:

Tip 1: Collaborate Effectively

Foster open communication and collaboration with architects, engineers, and contractors throughout the project. This collaborative approach ensures seamless integration between design intent and fabrication capabilities, leading to optimal outcomes.

Tip 2: Invest in Advanced Technology

Embrace advanced technology such as CNC machines and welding robots to enhance precision, efficiency, and productivity. These tools enable consistent, high-quality fabrication, minimizing errors and reducing production time.

Tip 3: Prioritize Quality Control

Implement rigorous quality control measures at every stage of the fabrication process. Conduct regular inspections, testing, and documentation to ensure that fabricated components meet the required specifications and industry best practices.

Tip 4: Choose Experienced Fabricators

Select steel fabricators with a proven track record of success and expertise in handling complex projects. Look for fabricators who possess the necessary certifications and adhere to industry standards, such as those established by the American Institute of Steel Construction (AISC).

Tip 5: Consider Cost-Effective Solutions

Explore cost-effective solutions without compromising quality. Discuss material options, design optimizations, and fabrication techniques with your fabricator to find the best balance between cost and performance.

Tip 6: Plan for Timely Execution

Plan the project timeline carefully, considering the lead time for design, engineering, fabrication, and installation. Allow ample time for each stage to ensure smooth project execution and avoid delays.

Tip 7: Ensure Proper Installation

Partner with experienced installers who specialize in steel structures. Proper installation is essential for the long-term performance and safety of the fabricated components.

Tip 8: Seek Professional Advice

Consult with industry experts or professional engineers for guidance on complex design or technical issues. Their expertise can help you make informed decisions and achieve optimal results.

By following these tips, you can navigate the steel fabrication process in Dallas effectively, ensuring the successful completion of your project with high-quality, durable, and cost-efficient steel structures.

Transition to the article’s conclusion: Emphasizing the importance of partnering with reputable steel fabricators in Dallas for exceptional project outcomes.

Conclusion

Steel fabrication plays a vital role in the construction, manufacturing, and transportation industries in Dallas. By partnering with reputable steel fabricators in the city, project owners and contractors can ensure the successful execution of their projects with high-quality, durable, and cost-effective steel structures.

The expertise, capabilities, and commitment to quality of Dallas steel fabricators set them apart in the industry. Their adherence to codes and standards, utilization of advanced technology, and collaborative approach guarantee exceptional results. By choosing experienced fabricators and following best practices, clients can achieve optimal outcomes, contributing to the city’s reputation for excellence in steel fabrication.