What exactly is a “steel fabrication unit project report”? Steel fabrication unit project reports are detailed documents that outline the scope, schedule, and budget for a steel fabrication project.

Editor’s Note: Steel fabrication unit project reports are essential for ensuring that steel fabrication projects are completed on time, within budget, and to the required specifications.

Our team has analyzed different steel fabrication unit project reports, and dug into the details, we have put together this guide to help you understand what a steel fabrication unit project report is, why it is important, and what it should include.

| Key Differences | Key Takeaways |

|---|---|

| Objective | To outline the scope, schedule, and budget for a steel fabrication project. |

| Importance | To ensure that steel fabrication projects are completed on time, within budget, and to the required specifications. |

| Sections | Introduction, Project Scope, Project Schedule, Project Budget, Conclusion |

Main Article Topics

- What is a steel fabrication unit project report?

- Why is a steel fabrication unit project report important?

- What should a steel fabrication unit project report include?

- How to write a steel fabrication unit project report

- Tips for writing a successful steel fabrication unit project report

Steel Fabrication Unit Project Report

A steel fabrication unit project report is a detailed document that outlines the scope, schedule, and budget for a steel fabrication project. It is an essential tool for ensuring that steel fabrication projects are completed on time, within budget, and to the required specifications. Key aspects of a steel fabrication unit project report include:

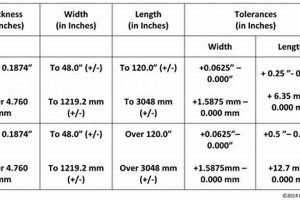

- Scope: The scope of the project should clearly define the work that is to be completed, including the type of steel fabrication, the dimensions of the fabricated steel, and the required quality standards.

- Schedule: The schedule should outline the timeline for the project, including the start and end dates, and the key milestones. It should also identify any potential risks to the schedule and contingency plans for mitigating those risks.

- Budget: The budget should outline the total cost of the project, including the cost of materials, labor, and overhead. It should also identify any potential cost overruns and contingency plans for mitigating those risks.

- Quality: The quality section should outline the quality standards that the fabricated steel must meet. It should also identify the inspection and testing procedures that will be used to ensure that the fabricated steel meets the required quality standards.

- Safety: The safety section should outline the safety procedures that will be followed during the project. It should also identify any potential hazards and contingency plans for mitigating those hazards.

- Environmental: The environmental section should outline the environmental impact of the project. It should also identify any measures that will be taken to minimize the environmental impact of the project.

- Sustainability: The sustainability section should outline the sustainability measures that will be incorporated into the project. It should also identify any measures that will be taken to minimize the environmental impact of the project.

- Innovation: The innovation section should outline any innovative technologies or processes that will be used in the project. It should also identify the potential benefits of using these technologies or processes.

- Lessons Learned: The lessons learned section should outline any lessons that were learned during the project. It should also identify any recommendations for improving the project process in the future.

These are just a few of the key aspects that should be included in a steel fabrication unit project report. By carefully considering all of these aspects, you can help ensure that your steel fabrication project is a success.

Scope

The scope of a steel fabrication unit project report is one of the most important aspects of the document. It defines the boundaries of the project and ensures that all stakeholders are on the same page about what is to be accomplished. A well-defined scope will help to prevent misunderstandings and change orders down the road.

-

Components of the Scope

The scope of a steel fabrication unit project report should include the following components:- A description of the work to be completed

- The type of steel fabrication required

- The dimensions of the fabricated steel

- The required quality standards

- The schedule for completing the work

- The budget for the project

-

Examples of Scope Statements

Here are some examples of scope statements for steel fabrication unit project reports:- Fabricate and erect a new steel frame building.

- Repair and replace the steel beams on a bridge.

- Manufacture and install a new steel staircase.

-

Implications of the Scope

The scope of a steel fabrication unit project report has a number of implications for the project. These implications include:- The cost of the project

- The schedule for completing the project

- The quality of the finished product

- The safety of the workers involved in the project

By carefully defining the scope of a steel fabrication unit project report, you can help to ensure that the project is completed on time, within budget, and to the required quality standards.

Schedule

The schedule is a critical component of any successful steel fabrication unit project report. It outlines the timeline for the project, including the start and end dates, and the key milestones. It is essential to identify any potential risks to the schedule and develop contingency plans for mitigating those risks.

-

Components of the Schedule

The schedule should include the following components:

- Start date: The date on which the project is scheduled to begin.

- End date: The date on which the project is scheduled to be completed.

- Key milestones: The major milestones that must be achieved in order to complete the project on time.

- Contingency plans: The plans that will be implemented if the project falls behind schedule.

-

Examples of Schedules

The following are examples of schedules for steel fabrication unit project reports:

-

Schedule for a new steel frame building: This schedule would include the following milestones:

- Design the building.

- Fabricate the steel.

- Erect the steel.

- Complete the building.

-

Schedule for a bridge repair: This schedule would include the following milestones:

- Inspect the bridge.

- Design the repairs.

- Fabricate the steel.

- Repair the bridge.

-

Schedule for a new steel frame building: This schedule would include the following milestones:

-

Implications of the Schedule

The schedule has a number of implications for the project. These implications include:

- Cost: The cost of the project will be affected by the schedule. A longer schedule will result in higher costs.

- Quality: The quality of the project will be affected by the schedule. A rushed schedule can lead to errors and defects.

- Safety: The safety of the workers involved in the project will be affected by the schedule. A rushed schedule can lead to accidents.

By carefully developing a schedule for a steel fabrication unit project report, you can help to ensure that the project is completed on time, within budget, and to the required quality standards.

Budget

The budget is a critical component of any successful steel fabrication unit project report. It outlines the total cost of the project, including the cost of materials, labor, and overhead. It is essential to identify any potential cost overruns and develop contingency plans for mitigating those risks.

-

Components of the Budget

The budget should include the following components:

- Cost of materials: The cost of the materials that will be used to fabricate the steel.

- Cost of labor: The cost of the labor that will be required to fabricate the steel.

- Cost of overhead: The cost of the overhead expenses that will be incurred during the project.

- Contingency fund: A fund that is set aside to cover unexpected costs.

-

Examples of Budgets

The following are examples of budgets for steel fabrication unit project reports:

-

Budget for a new steel frame building: This budget would include the following costs:

- Cost of materials: $100,000

- Cost of labor: $50,000

- Cost of overhead: $25,000

- Contingency fund: $10,000

-

Budget for a bridge repair: This budget would include the following costs:

- Cost of materials: $50,000

- Cost of labor: $25,000

- Cost of overhead: $10,000

- Contingency fund: $5,000

-

Budget for a new steel frame building: This budget would include the following costs:

-

Implications of the Budget

The budget has a number of implications for the project. These implications include:

- Cost: The cost of the project will be directly affected by the budget.

- Schedule: The schedule for the project may be affected by the budget.

- Quality: The quality of the project may be affected by the budget.

By carefully developing a budget for a steel fabrication unit project report, you can help to ensure that the project is completed on time, within budget, and to the required quality standards.

Quality

The quality section of a steel fabrication unit project report is essential for ensuring that the fabricated steel meets the required quality standards. This section should outline the quality standards that the fabricated steel must meet, as well as the inspection and testing procedures that will be used to ensure that the fabricated steel meets those standards.

The quality standards that are outlined in the quality section should be based on the intended use of the fabricated steel. For example, if the fabricated steel is going to be used in a structural application, then the quality standards should be based on the applicable building codes and standards. The quality section should also identify the inspection and testing procedures that will be used to ensure that the fabricated steel meets the required quality standards.

The inspection and testing procedures that are outlined in the quality section should be based on the specific requirements of the project. For example, if the fabricated steel is going to be used in a safety-critical application, then the inspection and testing procedures should be more rigorous than if the fabricated steel is going to be used in a non-critical application.

By carefully developing the quality section of a steel fabrication unit project report, you can help to ensure that the fabricated steel meets the required quality standards. This will help to ensure that the steel fabrication unit project is a success.

Table: Quality Standards for Steel Fabrication

| Quality Standard | Description |

|---|---|

| ASTM A36 | Standard Specification for Carbon Structural Steel |

| ASTM A572 | Standard Specification for High-Strength Low-Alloy Columbium-Vanadium Structural Steel |

| ASTM A913 | Standard Specification for High-Strength Low-Alloy Steel Shapes of Structural Quality, Produced by the Quenching and Self-Tempering Process |

Safety

The safety section of a steel fabrication unit project report is essential for ensuring that the project is completed without any accidents or injuries. This section should outline the safety procedures that will be followed during the project, as well as identify any potential hazards and contingency plans for mitigating those hazards.

The safety procedures that are outlined in the safety section should be based on the specific requirements of the project. For example, if the project involves working with heavy machinery, then the safety procedures should include instructions on how to safely operate the machinery. The safety section should also identify any potential hazards that could be encountered during the project, such as working at heights or in confined spaces. For each hazard, the safety section should include a contingency plan for mitigating the hazard.

By carefully developing the safety section of a steel fabrication unit project report, you can help to ensure that the project is completed safely and without any accidents or injuries.

Table: Safety Procedures for Steel Fabrication

| Safety Procedure | Description |

|---|---|

| Wear appropriate personal protective equipment (PPE) | This includes hard hats, safety glasses, gloves, and steel-toed boots. |

| Use machinery safely | This includes following all operating instructions and being aware of potential hazards. |

| Work in a safe environment | This includes keeping the work area clean and free of tripping hazards. |

| Be aware of potential hazards | This includes being aware of overhead hazards, electrical hazards, and chemical hazards. |

| Have a contingency plan for emergencies | This includes knowing what to do in case of a fire, accident, or other emergency. |

Environmental

The environmental section of a steel fabrication unit project report is essential for ensuring that the project is completed in a sustainable manner. This section should outline the environmental impact of the project, as well as identify any measures that will be taken to minimize the environmental impact of the project.

-

Air pollution

Steel fabrication can generate air pollution in the form of dust and fumes. This can be minimized by using dust collectors and other pollution control devices.

-

Water pollution

Steel fabrication can also generate water pollution in the form of wastewater. This can be minimized by using water treatment systems.

-

Solid waste

Steel fabrication can also generate solid waste in the form of scrap metal. This can be minimized by recycling scrap metal.

-

Noise pollution

Steel fabrication can also generate noise pollution. This can be minimized by using noise dampening materials.

By carefully developing the environmental section of a steel fabrication unit project report, you can help to ensure that the project is completed in a sustainable manner.

Sustainability

Sustainability is a key consideration in any steel fabrication unit project report. The sustainability section of the report should outline the sustainability measures that will be incorporated into the project, as well as identify any measures that will be taken to minimize the environmental impact of the project.

-

Use of recycled materials

One way to reduce the environmental impact of a steel fabrication project is to use recycled materials. Recycled steel is just as strong and durable as new steel, but it has a much lower environmental impact. Using recycled steel can help to conserve natural resources and reduce greenhouse gas emissions.

-

Energy efficiency

Another way to reduce the environmental impact of a steel fabrication project is to improve energy efficiency. This can be done by using energy-efficient equipment and processes, and by designing the project to minimize energy consumption. Energy efficiency can help to reduce operating costs and greenhouse gas emissions.

-

Waste reduction

Waste reduction is another important aspect of sustainability in steel fabrication. This can be done by reducing the amount of waste generated during the fabrication process, and by recycling or reusing waste materials. Waste reduction can help to conserve resources and reduce landfill waste.

-

Environmental management

Finally, it is important to have a comprehensive environmental management plan in place for any steel fabrication project. This plan should outline the measures that will be taken to protect the environment during the project, and to mitigate any potential environmental impacts. Environmental management can help to ensure that the project is completed in a sustainable manner.

By incorporating sustainability measures into a steel fabrication unit project report, you can help to reduce the environmental impact of the project and contribute to a more sustainable future.

Innovation

Innovation is essential for the success of any steel fabrication unit project report. By incorporating innovative technologies and processes into your project, you can improve efficiency, reduce costs, and create a more sustainable product. Some of the most common innovative technologies and processes used in steel fabrication include:

- Computer-aided design (CAD): CAD software allows engineers to design and model steel structures in 3D. This can help to identify potential problems early in the design process and reduce the need for costly rework.

- Computer-aided manufacturing (CAM): CAM software is used to control the operation of CNC machines. This can help to improve accuracy and efficiency, and reduce the risk of errors.

- Laser cutting: Laser cutting is a precise and efficient way to cut steel. It can be used to create complex shapes and designs that would be difficult or impossible to create using traditional methods.

- Robotic welding: Robotic welding is a fast and accurate way to weld steel. It can be used to weld complex assemblies and reduce the need for manual labor.

The potential benefits of using innovative technologies and processes in steel fabrication are significant. By incorporating these technologies and processes into your project, you can:

- Improve efficiency: Innovative technologies and processes can help to improve efficiency by automating tasks, reducing errors, and improving communication.

- Reduce costs: Innovative technologies and processes can help to reduce costs by reducing material waste, energy consumption, and labor costs.

- Create a more sustainable product: Innovative technologies and processes can help to create a more sustainable product by reducing environmental impact and improving durability.

If you are considering incorporating innovative technologies and processes into your steel fabrication unit project report, it is important to do your research and choose the right technologies and processes for your project. You should also consider the cost of implementing these technologies and processes, as well as the potential benefits. By carefully considering all of these factors, you can make an informed decision about whether or not to incorporate innovative technologies and processes into your project.

Lessons Learned

The “Lessons Learned” section is an essential component of any steel fabrication unit project report. It provides an opportunity to reflect on the project and identify what went well and what could be improved. By carefully considering the lessons learned, you can help to ensure that future projects are more successful.

There are many different types of lessons that can be learned from a steel fabrication unit project. These lessons can be related to any aspect of the project, from the planning and design phase to the fabrication and construction phase. Some common types of lessons learned include:

- Lessons learned about the project scope

- Lessons learned about the project schedule

- Lessons learned about the project budget

- Lessons learned about the project quality

- Lessons learned about the project safety

- Lessons learned about the project environmental impact

- Lessons learned about the project sustainability

- Lessons learned about the project innovation

It is important to note that the “Lessons Learned” section should not be a laundry list of everything that went wrong on the project. Instead, it should focus on the most important lessons that were learned and the recommendations for improving the project process in the future.

By carefully considering the lessons learned from a steel fabrication unit project, you can help to ensure that future projects are more successful. The following are some examples of how lessons learned can be used to improve future projects:

- Lessons learned about the project scope can be used to better define the scope of future projects and avoid scope creep.

- Lessons learned about the project schedule can be used to create more realistic schedules for future projects and avoid delays.

- Lessons learned about the project budget can be used to better estimate the cost of future projects and avoid cost overruns.

- Lessons learned about the project quality can be used to improve the quality of future projects and avoid defects.

- Lessons learned about the project safety can be used to improve the safety of future projects and avoid accidents.

- Lessons learned about the project environmental impact can be used to reduce the environmental impact of future projects.

- Lessons learned about the project sustainability can be used to improve the sustainability of future projects.

- Lessons learned about the project innovation can be used to incorporate more innovative technologies and processes into future projects.

By taking the time to learn from the past, you can help to ensure that future steel fabrication unit projects are more successful.

Table: Examples of Lessons Learned

| Lesson Learned | Recommendation for Improving the Project Process in the Future |

|---|---|

| The project scope was not well-defined, which led to scope creep and delays. | In the future, the project scope should be clearly defined and agreed upon by all stakeholders before the project begins. |

| The project schedule was unrealistic, which led to delays and cost overruns. | In the future, the project schedule should be realistic and based on the actual time required to complete the work. |

| The project budget was underestimated, which led to cost overruns. | In the future, the project budget should be carefully estimated and based on the actual cost of the materials and labor required to complete the work. |

| The project quality was not up to par, which led to rework and delays. | In the future, the project quality should be carefully controlled and inspected throughout the project. |

| The project safety was not adequate, which led to accidents and injuries. | In the future, the project safety should be carefully planned and implemented throughout the project. |

FAQs about Steel Fabrication Unit Project Reports

Steel fabrication unit project reports are essential documents that outline the scope, schedule, and budget for a steel fabrication project. They are used to ensure that projects are completed on time, within budget, and to the required quality standards.

Question 1: What is the purpose of a steel fabrication unit project report?

Answer: A steel fabrication unit project report is a comprehensive document that outlines the scope, schedule, and budget for a steel fabrication project. It is used to ensure that projects are completed on time, within budget, and to the required quality standards.

Question 2: What are the key components of a steel fabrication unit project report?

Answer: The key components of a steel fabrication unit project report include the scope of work, the project schedule, the project budget, the quality control plan, the safety plan, and the environmental impact assessment.

Question 3: Who is responsible for preparing a steel fabrication unit project report?

Answer: The project engineer is typically responsible for preparing the steel fabrication unit project report. However, the project manager may also be involved in the preparation of the report.

Question 4: What are the benefits of using a steel fabrication unit project report?

Answer: The benefits of using a steel fabrication unit project report include improved communication between the project team and stakeholders, reduced project risks, and increased project efficiency.

Question 5: What are some common challenges associated with steel fabrication unit project reports?

Answer: Some common challenges associated with steel fabrication unit project reports include gathering accurate data, developing realistic schedules, and managing project risks.

Question 6: How can I improve the quality of my steel fabrication unit project reports?

Answer: You can improve the quality of your steel fabrication unit project reports by using clear and concise language, providing accurate and complete information, and following a consistent format.

Summary: Steel fabrication unit project reports are essential for ensuring the success of steel fabrication projects. By carefully preparing and managing these reports, you can help to ensure that your projects are completed on time, within budget, and to the required quality standards.

Transition: For more information on steel fabrication unit project reports, please consult the following resources:

- Wikipedia: Steel Fabrication Unit Project Report

- YouTube: Steel Fabrication Unit Project Report

- Comparison: Steel Fabrication Unit Project Report

Tips for Writing a Steel Fabrication Unit Project Report

Steel fabrication unit project reports are essential for ensuring the success of steel fabrication projects. By following these tips, you can improve the quality of your project reports and help to ensure that your projects are completed on time, within budget, and to the required quality standards.

Tip 1: Use clear and concise language.

Your project report should be easy to read and understand. Avoid using technical jargon and acronyms that your readers may not be familiar with. Instead, use clear and concise language that is easy to follow.

Tip 2: Provide accurate and complete information.

Your project report should contain all of the information that is necessary for your readers to understand the scope, schedule, and budget of your project. This information should be accurate and complete. Do not omit any important details.

Tip 3: Follow a consistent format.

Your project report should follow a consistent format. This will make it easier for your readers to find the information they are looking for. Use headings and subheadings to organize your report and make it easy to navigate.

Tip 4: Get feedback from others.

Once you have written your project report, get feedback from others. This could include your colleagues, your supervisor, or even your clients. Getting feedback from others will help you to identify any areas that need improvement.

Tip 5: Proofread your report carefully.

Before you submit your project report, proofread it carefully for any errors. This includes checking for typos, grammatical errors, and formatting errors. A well-proofread report will make a good impression on your readers.

Summary: By following these tips, you can improve the quality of your steel fabrication unit project reports and help to ensure that your projects are completed on time, within budget, and to the required quality standards.

Conclusion

A steel fabrication unit project report is a critical document that outlines the scope, schedule, and budget for a steel fabrication project. It is an essential tool for ensuring that steel fabrication projects are completed on time, within budget, and to the required quality standards.

This article has explored the key components of a steel fabrication unit project report, as well as the benefits of using a project report. We have also provided tips for writing a successful steel fabrication unit project report.

By following the tips in this article, you can improve the quality of your steel fabrication unit project reports and help to ensure that your projects are a success.